Combined drilling unit

A unit and component technology, applied in cutting machinery, slitting machinery, drilling equipment, etc., can solve the problems of small drilling depth, large space occupation, waste of time, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

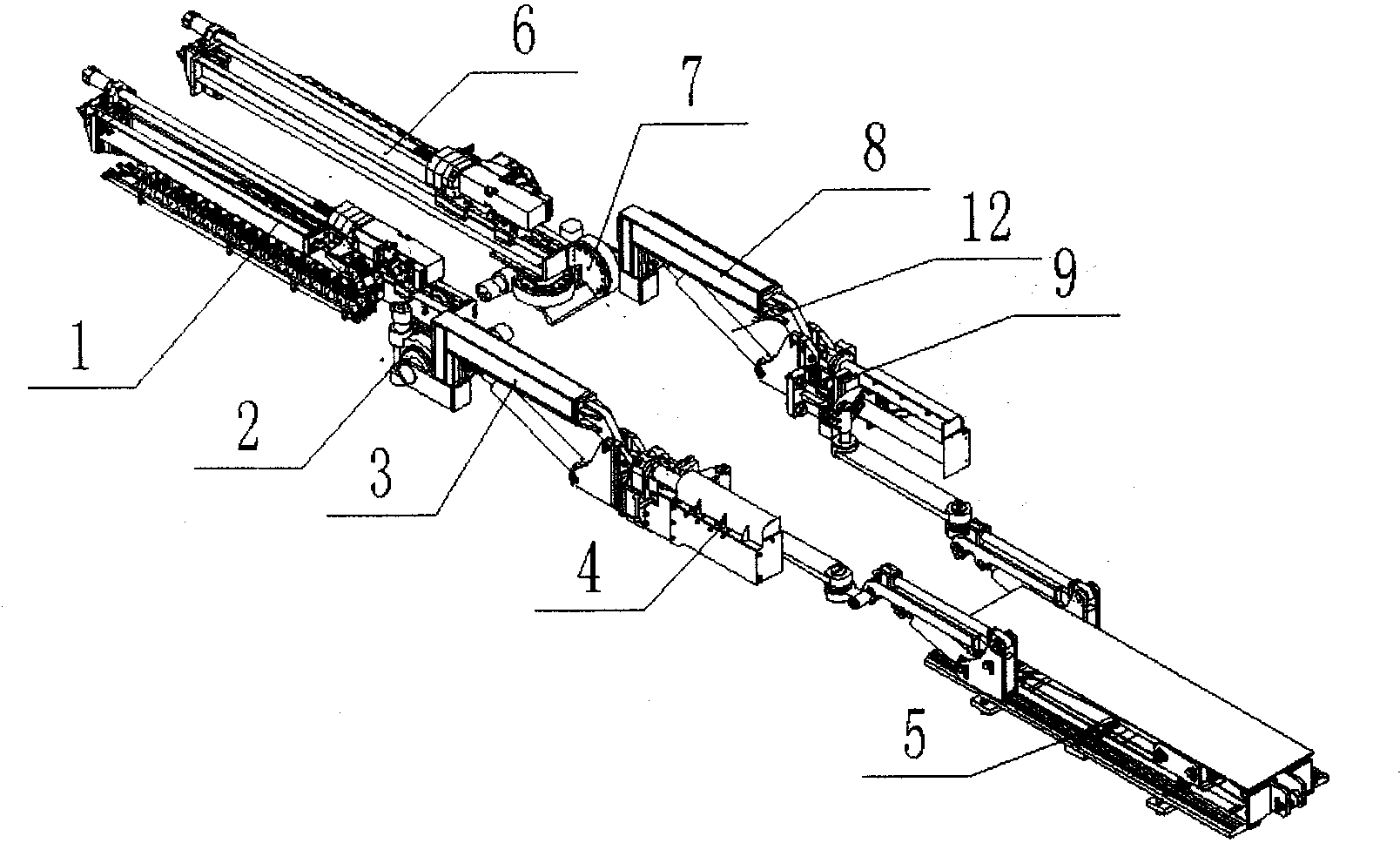

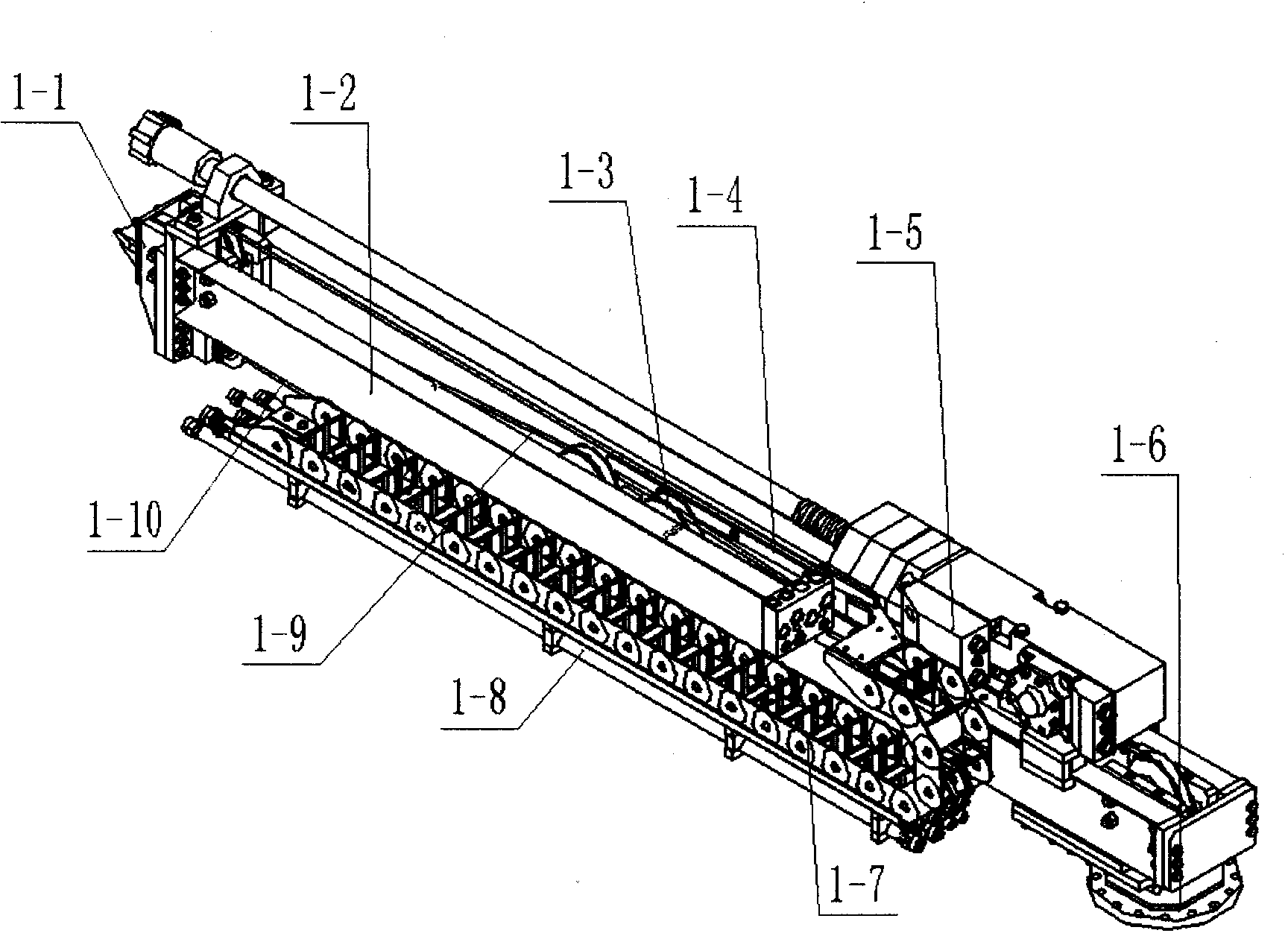

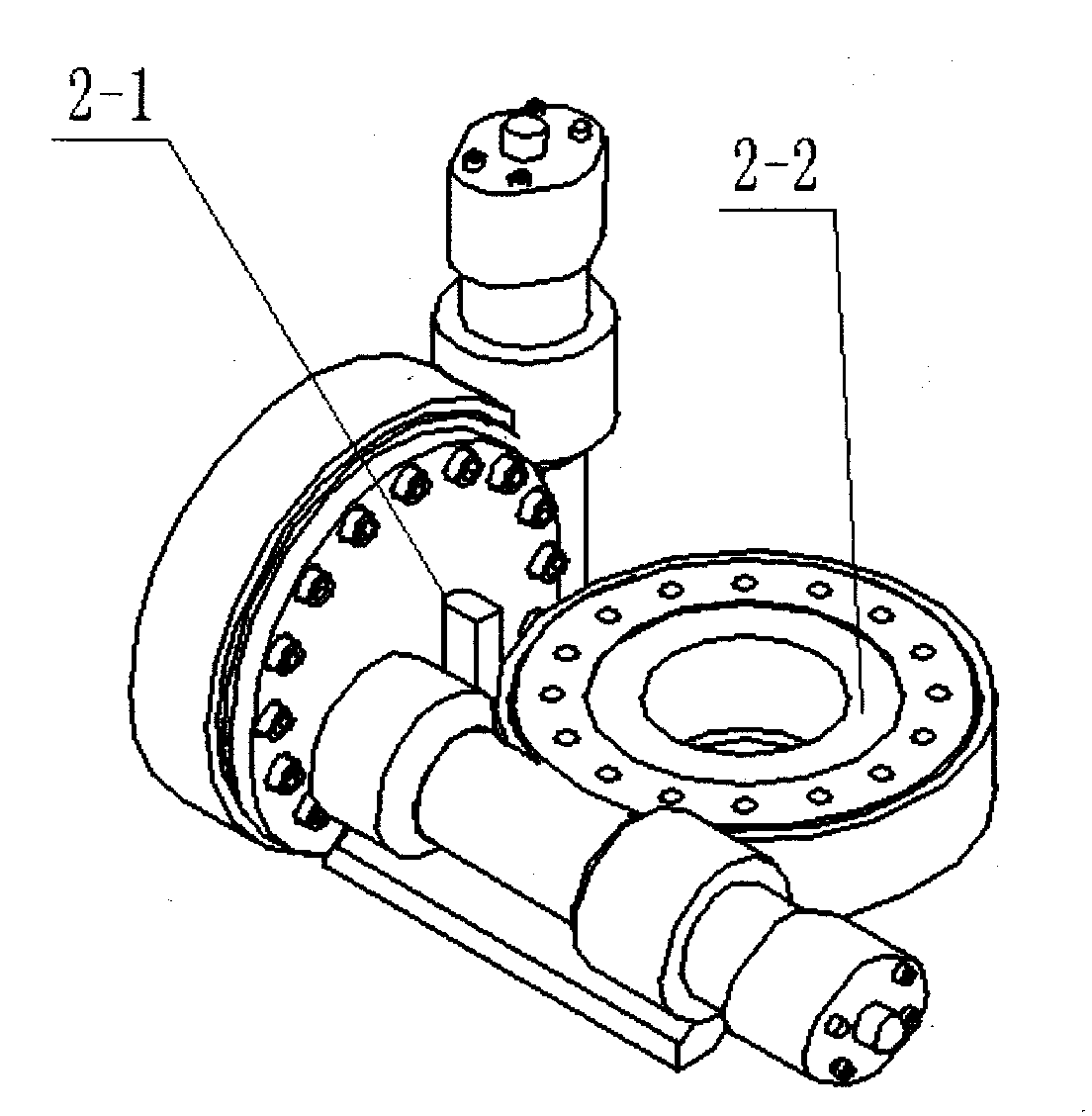

[0031] Example: figure 1 — Figure 10 The combined rock drilling unit is shown in the figure. The left hydraulic rock drilling unit and the right hydraulic rock drilling unit have two distributions: the space position of the rock drilling hole and the position of the cutting space. The fixed seat is rotated and fixed by the locking handle. The base forms two states of full restraint and non-full restraint. The rotating shaft seat moves through the closing bolt and the fixed seat forms two states of full restraint and non-full restraint. The full restraint of the fixed seat and the fixed base and the fixed The non-full constraint combination of the seat is the rock drilling space position of the left and right hydraulic rock drilling components, the non-full constraint combination of the fixed seat and the fixed base and the full constraint combination of the rotating shaft seat and the fixed seat are the left and right hydraulic drilling components. The cut-space location...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com