Electrostatic spinning device for manufacturing nano fibers in electromagnetic field with coupling method

An electrospinning and nanofiber technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of unstable jet flow, disordered collection fibers, etc., and achieve simple structure, simple control, and technological process. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

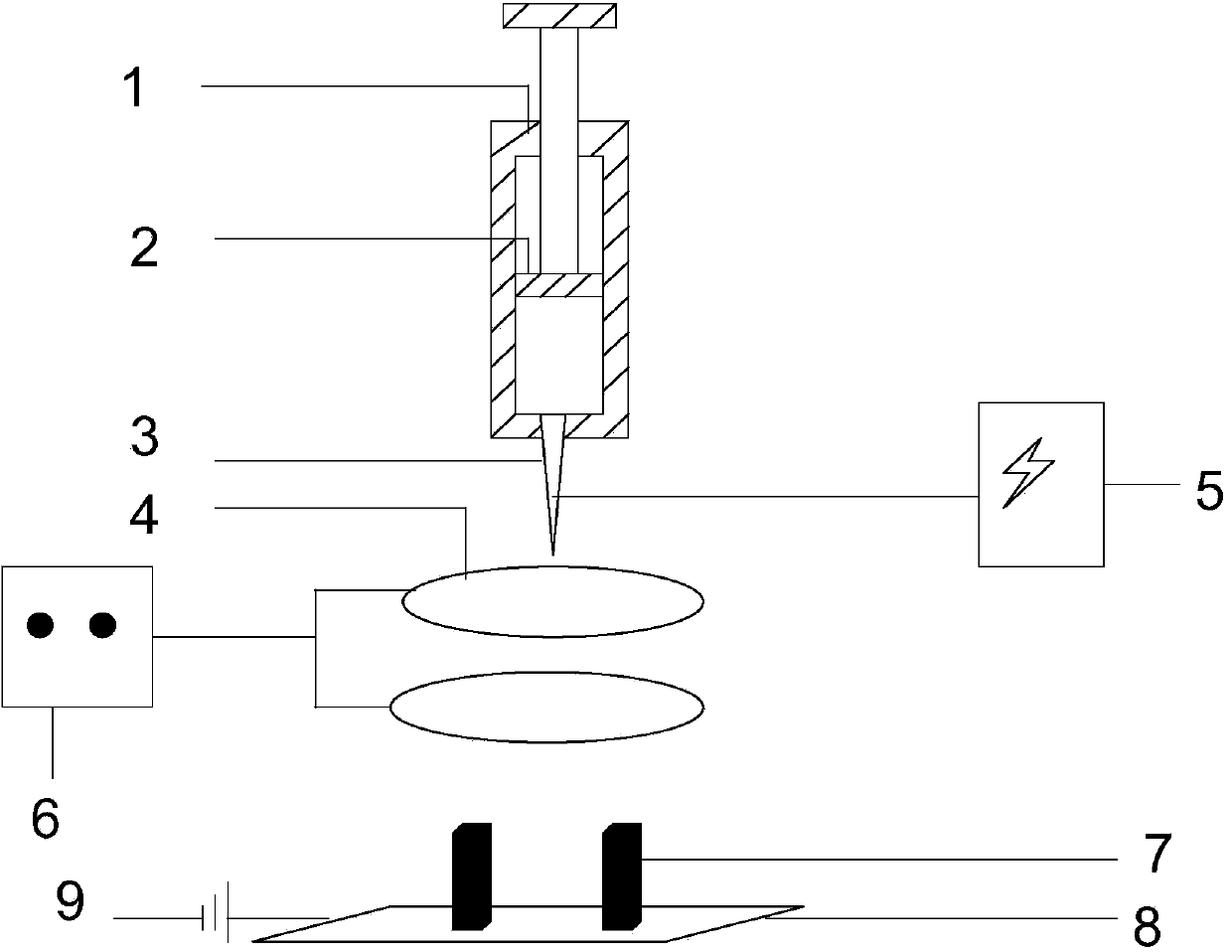

[0018] The invention discloses an electrostatic spinning device capable of preparing ordered nanofibers. The electrostatic spinning device uses a magnetic field coupling method to prepare ordered nanofibers.

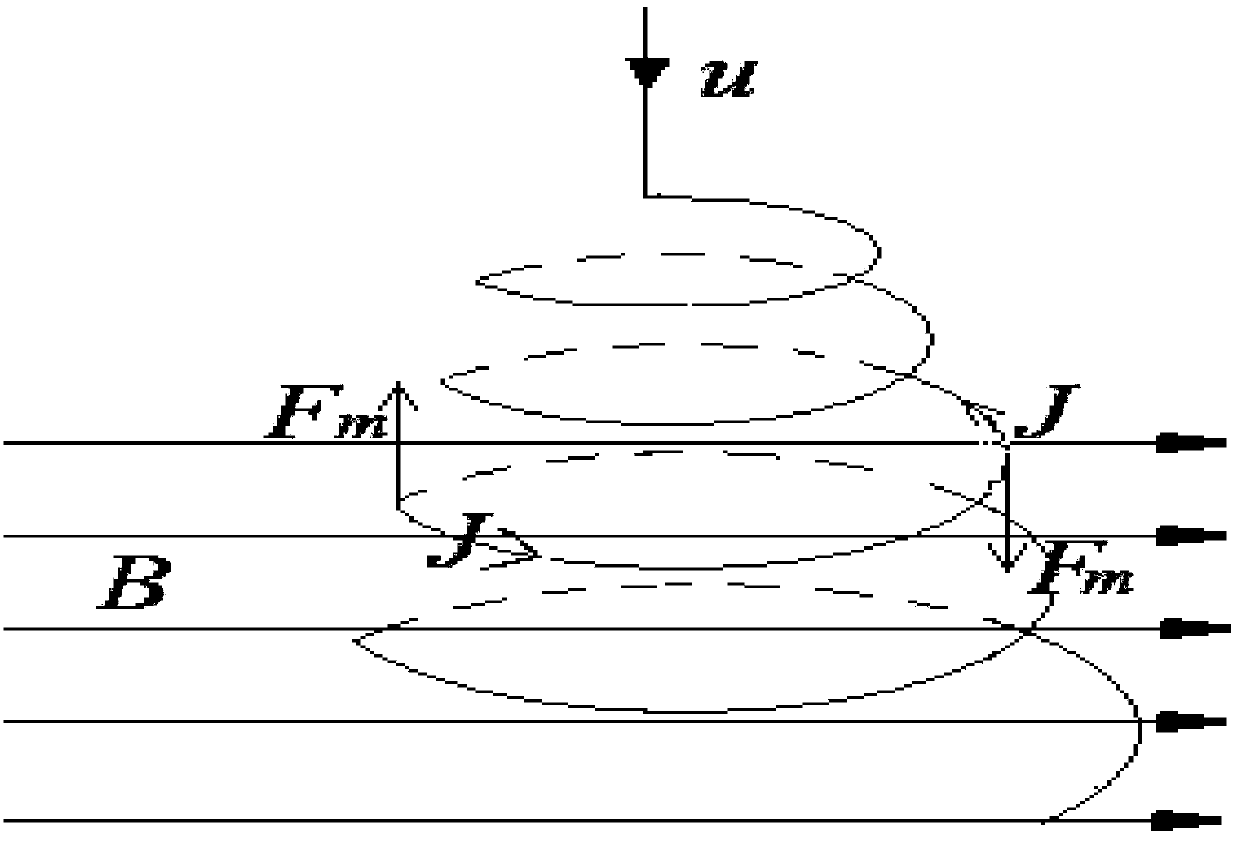

[0019] The electrospinning device for preparing nanofibers by the electromagnetic field coupling method includes a barrel, a piston arranged in the barrel and capable of moving in the barrel, a spinneret arranged at one end of the barrel and connected to the barrel, and connected to the The high-voltage power supply device on the spinneret, the receiving plate corresponding to the position of the spinneret and the grounding power line for the grounding of the receiving plate, the electrospinning device is also provided between the spinneret and the receiving plate and facing The conductive coil of the spinneret and the receiving plate, in the spinning area, a magnetic field generating device forming a parallel magnetic field is arranged in the receiving area of the fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com