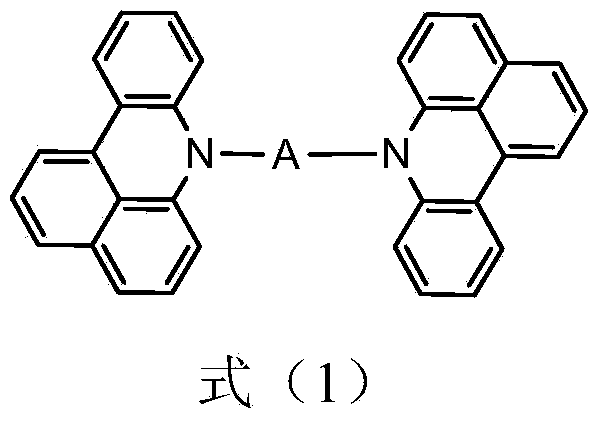

Organic electroluminescent material and preparation method thereof

An electroluminescent material and luminescent technology, applied in the direction of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems that the luminous efficiency of luminescent materials cannot meet the requirements of OLEDs, etc., and achieve improved luminous efficiency, high purity, and good Effects of planar structures and conjugated systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

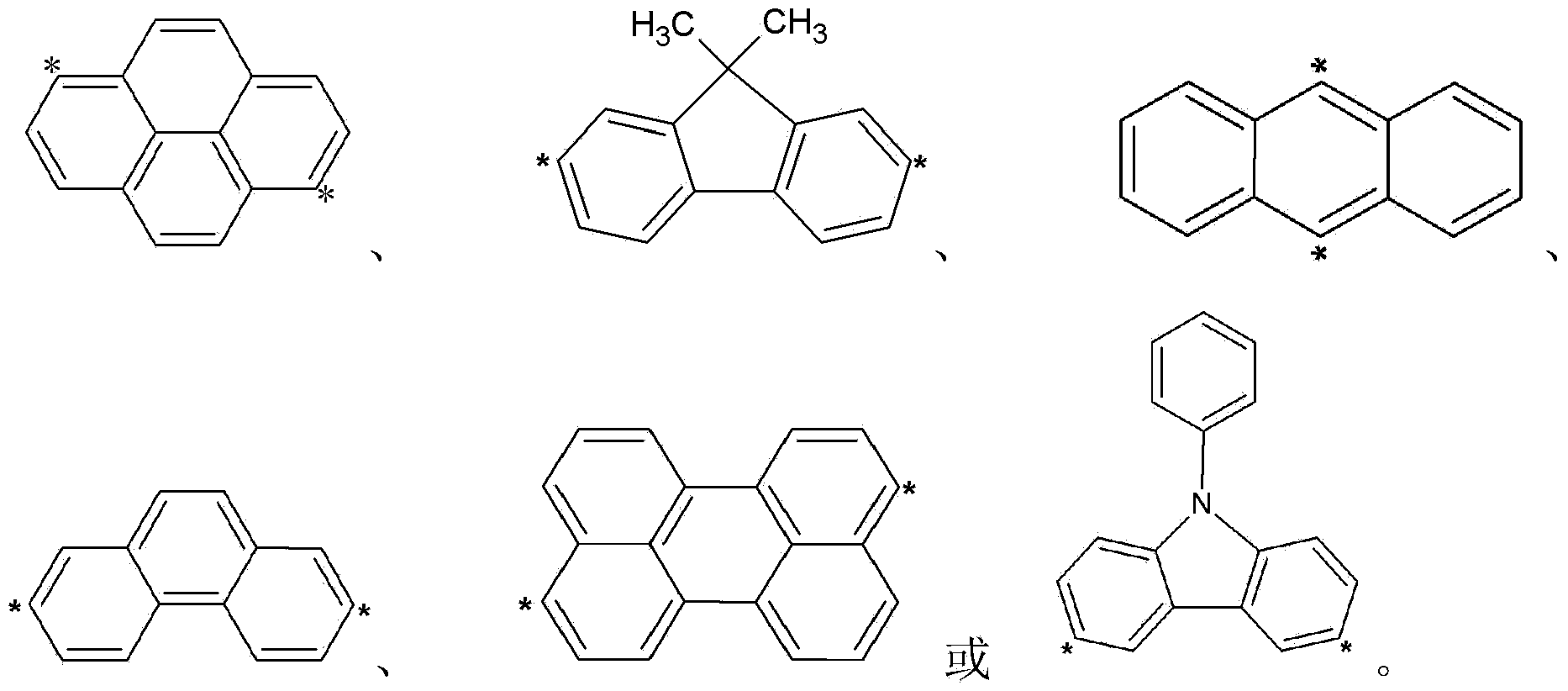

[0026] Embodiment 1: the synthesis of compound 001

[0027] Concrete synthetic route is as follows:

[0028]

[0029] Weigh 35.79g of 1,6-dibromopyrene, 64.18g of 7H-benzoacridine, 13.46g of potassium tert-butoxide, 0.41g of palladium (II) acetate, and 0.45g of tri-tert-butylphosphine, dissolve them in 250ml of toluene, and Under the protection of nitrogen, react at 80°C for 10 hours. Filter the reaction solution, purify the obtained crude product with silica gel chromatography, then recrystallize the obtained solid crude product with toluene, and dry to obtain 53.78g yellow-white solid bisbenzoacridine compound 001, with a yield of more than 85%, HPLC The purity is greater than 98%. Mass spectrum: calculated value 632.75; found value 632.73. Elemental analysis: calculated value C: 91.11%; H: 4.46%; N: 4.43%; tested value C: 91.13%; H: 4.47%; N: 4.40%.

Embodiment 2

[0030] Embodiment 2: the synthesis of compound 002

[0031] Concrete synthetic route is as follows:

[0032]

[0033] Weigh 35.20 g of 2,7-dibromo-9,9-dimethylfluorene, 67.35 g of 7H-benzoacridine, 14.36 g of potassium tert-butoxide, 0.48 g of palladium (II) acetate, and 0.54 g of tri-tert-butylphosphine g, dissolved in 250ml of toluene, and reacted at 82°C for 11 hours. Filter the reaction solution, purify the obtained crude product with silica gel chromatography, recrystallize the obtained solid crude product with toluene, and dry to obtain 51.85g of yellow-white solid bisbenzoacridine compound 002, with a yield of more than 83% and HPLC purity Greater than 98%. Mass Spectrum: Calculated 624.77; Found 624.75. Elemental analysis: calculated value C: 90.35%; H: 5.16%; N: 4.48%; tested value C: 90.34%; H: 5.18%; N: 4.47%.

Embodiment 3

[0034] Embodiment 3: the synthesis of compound 003

[0035] Concrete synthetic route is as follows:

[0036]

[0037] Weigh 33.60g of 9,10-dibromoanthracene, 69.52g of 7H-benzoacridine, 15.26g of potassium tert-butoxide, 0.56g of palladium(II) acetate, and 0.63g of tri-tert-butylphosphine, dissolve them in 250ml of toluene, and React at 84°C for 12 hours. Filter the reaction solution, purify the obtained crude product with silica gel chromatography, recrystallize the obtained solid crude product with toluene, and dry to obtain 52.35g of yellow-white solid bisbenzoacridine compound 003, with a yield of more than 86%, HPLC purity Greater than 98%. Mass Spectrum: Calcd. 608.73; Tested 608.71. Elemental analysis: calculated value C: 90.76%; H: 4.64%; N: 4.60%; tested value C: 90.77%; H: 4.63%; N: 4.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com