Polyphenyl ether/polyamide alloy material and preparation method thereof

An alloy material and polyphenylene ether technology, which is applied in the field of ultra-low shrinkage and high toughness polyphenylene ether/polyamide alloy material and its preparation, can solve the problem that the comprehensive performance needs to be further improved, the comprehensive performance affecting the dimensional stability, the large shrinkage rate, etc. problem, to achieve the effect of easy industrialized large-scale production, high toughness, ultra-low shrinkage

Active Publication Date: 2014-03-05

CGN JUNER NEW MATERIALS +1

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This technical solution improves the interfacial strength through the compound containing isocyanate group of the compatibilizer, and the comprehensive performance of the composition is excellent, especially the impact resistance and heat resistance are good, but t

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Login to View More

Abstract

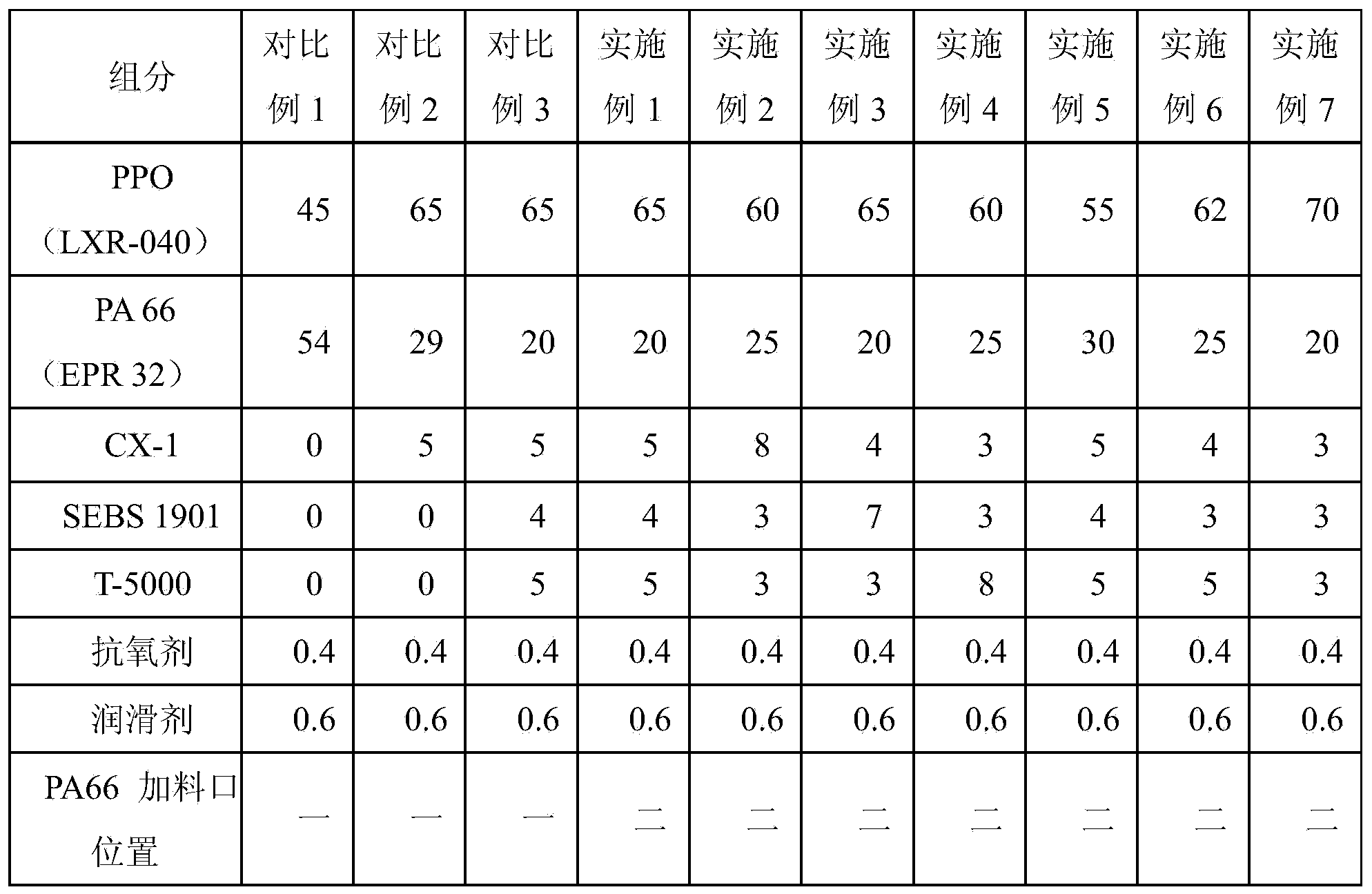

The invention discloses a polyphenyl ether/polyamide alloy material, which is composed of the following components in percentage by weight: 55 to 70% of polyphenyl ether PPO, 20 to 35% of polyamide PA66, 3 to 10% of compatilizer, 2 to 10% of flexibilizer, 1 to 10% of contraction rate conditioning agent, and 0.3 to 5% of auxiliary agent. All components are prepared in a proper ratio so as to generate an ideal synergetic effect to enable the composite material to have a super low contraction rate and a high toughness, so the composite material has a size stability and excellent comprehensive property, and is suitable for injection moulding of parts of automobiles or precision electronic and electric appliances. The invention also discloses a preparation method of the polyphenyl ether/polyamide alloy material. The method can be achieved by a conventional double-screw extruder through controlling the material feeding position and temperature, has the advantages of simple preparation, easy control, easy application to industrial mass production, and has a vast application prospect.

Description

technical field [0001] The invention relates to the field of polyphenylene ether / polyamide alloy materials, in particular to an ultra-low shrinkage and high-toughness polyphenylene ether / polyamide alloy material and a preparation method thereof. Background technique [0002] Polyphenylene ether (PPO or PPE) resin has good heat resistance, dimensional stability and hydrolysis resistance. Polyamide has excellent solvent resistance and good processability, but polyamide has poor heat resistance and dimensional stability. Alloying polyphenylene ether and polyamide can improve the poor dimensional stability and moisture absorption of polyamide, and polyamide can improve the processing performance, chemical resistance and temperature resistance of polyphenylene ether resin. With the development of the automobile industry, light weight and energy saving, replacing steel with plastic has become the theme of the development of automobile materials. Polyphenylene ether / polyamide all...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L71/12C08L77/06C08L51/08C08L51/00B29B9/06B29C47/92B29C48/92

Inventor 黄瑞杰陈继奏黄志杰

Owner CGN JUNER NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com