Solid-phase fragment synthetic method of exenatide

A technology of exenatide and a synthesis method, which is applied in the field of solid-phase peptide synthesis, can solve the problems of low product content, high purification cost, low efficiency of synthesizing long peptides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

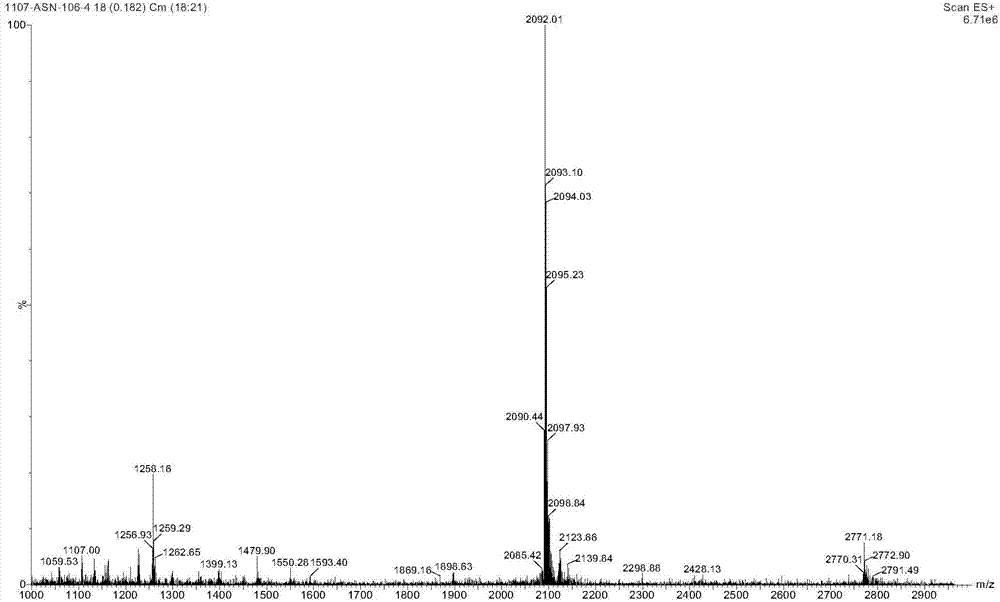

Image

Examples

Embodiment 1

[0043] 1. Synthesis of Fmoc-Gly-Pro-Ser(tBu)-Ser(tBu)-Gly-Ala-Pro-Pro-Pro-Ser(tBu)-MBHA Resin

[0044] (1) Synthesis of Fmoc-Ser(tBu)-MBHA Resin

[0045] Add 1.0g Fmoc-Rink Amide MBHA Resin into the reactor, add 10mL N,N-dimethylformamide to soak the resin for 30 minutes to fully swell the resin, remove N,N-dimethylformamide by suction filtration, and add to the reaction Add 10mL of piperidine and N,N-dimethylformamide with a volume ratio of 1:4 to the container, react for 5 minutes, remove the mixture by suction filtration, then add 10mL of piperidine and N,N-dimethylformamide The volume ratio of formamide is a mixture of 1:4, react for 20 minutes, filter with suction, wash the resin twice with isopropanol, and wash the resin three times with N,N-dimethylformamide, 10 mL each time, to complete the Fmoc- Rink Amide MBHA Resin de-Fmoc- twice, add 10mL N,N-dimethylformamide, 0.53g Fmoc-Ser(tBu)-OH, 0.19g 1-hydroxybenzotriazole, 0.44g benzene Ditriazole-N,N,N',N'-tetramethyluro...

Embodiment 2

[0073] In step 1 of this implementation, Fmoc-Ser(tBu)-OH, Fmoc-Pro-OH, Fmoc-Pro-OH, Fmoc-Pro-OH, Fmoc-Ala-OH, Fmoc-Gly-OH, Fmoc-Ser( The molar ratio of tBu)-OH, Fmoc-Ser(tBu)-OH, Fmoc-Pro-OH, Fmoc-Gly-OH and Fmoc-Rink Amide MBHA Resin is 2:1, Fmoc-Rink Amide MBHA Resin and 1- The molar ratio of hydroxybenzotriazole, benzotriazole-N,N,N′,N′-tetramethylurea tetrafluoroboric acid, N,N′-diisopropylethylamine is 1:2:2 : 2, other steps of this step are identical with embodiment 1. In step 2 of this example, the molar ratios of Fmoc-Asn(Trt)-OH, Fmoc-Lys(Boc)-OH and 2-chlorotrityl chloride resin are all 2:1, 2-chlorotrityl chloride resin and 1-hydroxybenzene The molar ratio of propanetriazole, benzotriazole-N,N,N',N'-tetramethylurea tetrafluoroboric acid, N,N'-diisopropylethylamine is 1:2:2:2, Other steps of this step are the same as in Example 1. In steps 3 to 6 of this example, 2-chlororityl chloride resin and Fmoc-amino acid, 1-hydroxybenzotriazole, benzotriazole-N,N,N',N'-tet...

Embodiment 3

[0075] In step 1 of this implementation, Fmoc-Ser(tBu)-OH, Fmoc-Pro-OH, Fmoc-Pro-OH, Fmoc-Pro-OH, Fmoc-Ala-OH, Fmoc-Gly-OH, Fmoc-Ser( The molar ratio of tBu)-OH, Fmoc-Ser(tBu)-OH, Fmoc-Pro-OH, Fmoc-Gly-OH and Fmoc-Rink Amide MBHA Resin is 3:1, Fmoc-Rink Amide MBHA Resin and 1- The molar ratio of hydroxybenzotriazole, benzotriazole-N,N,N′,N′-tetramethylurea tetrafluoroboric acid, N,N′-diisopropylethylamine is 1:3:3 : 3, other steps of this step are identical with embodiment 1. In step 2 of this example, the molar ratios of Fmoc-Asn(Trt)-OH, Fmoc-Lys(Boc)-OH and 2-chlorotrityl chloride resin are all 3:1, 2-chlorotrityl chloride resin and 1-hydroxybenzene The molar ratio of propanetriazole, benzotriazole-N,N,N',N'-tetramethyluronium tetrafluoroboric acid, N,N'-diisopropylethylamine is 1:3:3:3, Other steps of this step are the same as in Example 1. In steps 3 to 6 of this example, 2-chlororityl chloride resin and Fmoc-amino acid, 1-hydroxybenzotriazole, benzotriazole-N,N,N',N'-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com