Preparation method of ultrapure isopropanol

A technology of ultra-pure isopropanol and isopropanol, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of difficult cost reduction, high content of impurity metal ions, and difficult post-processing, etc. Achieve the effects of reducing clogging, low content of impurity metal ions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

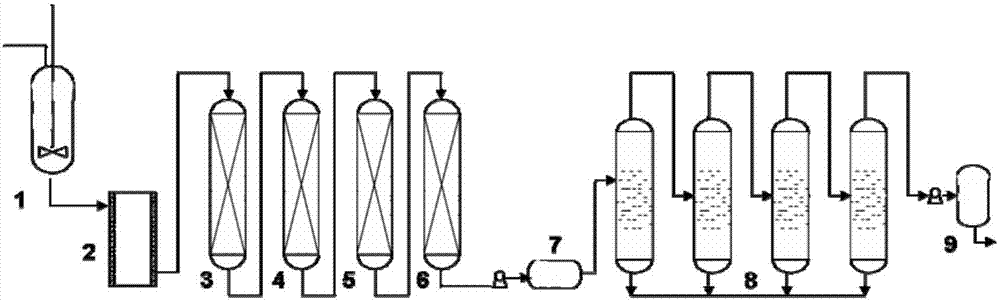

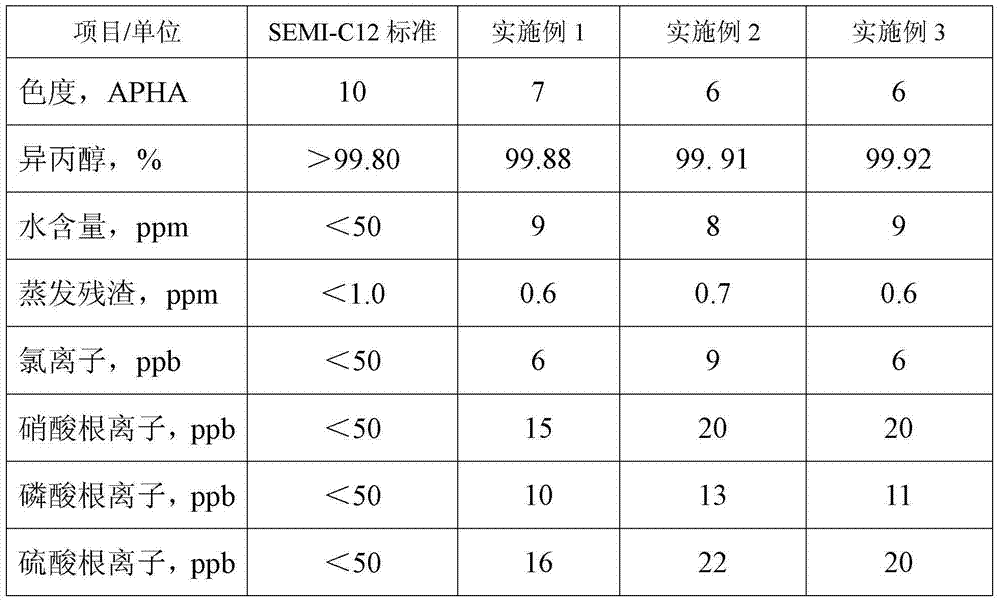

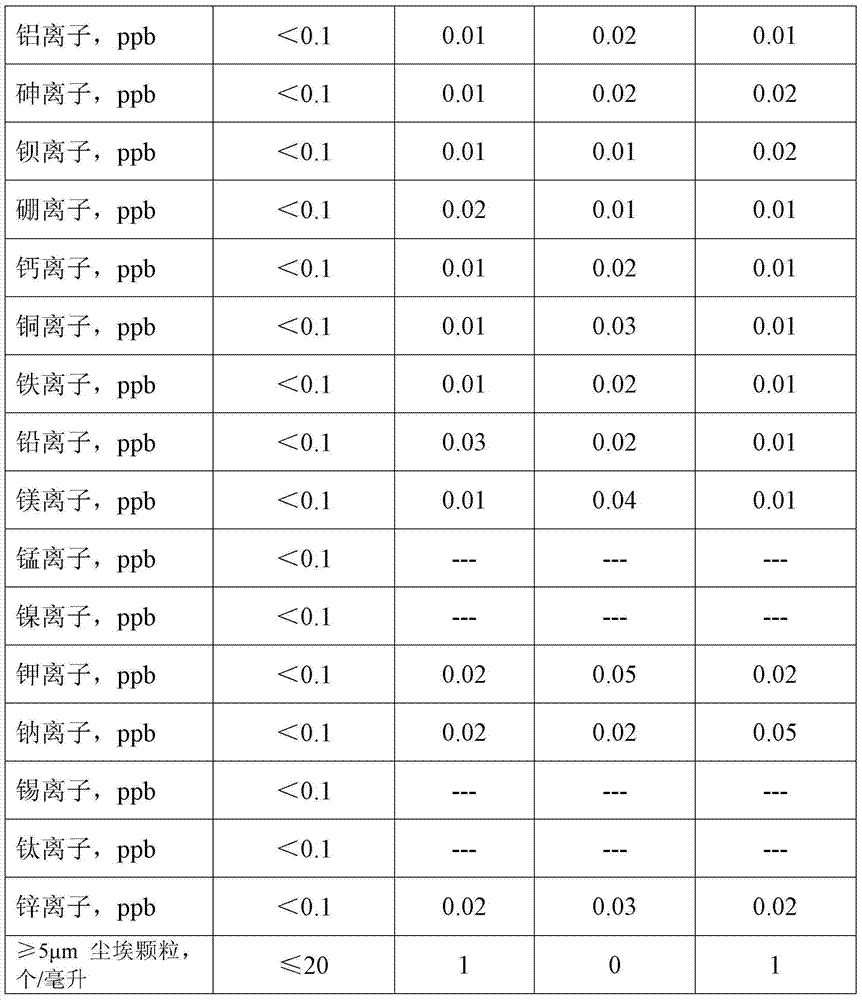

[0023] refer to figure 1 , at normal temperature and pressure, add 2.0g of ethylenediaminetetraacetic acid disodium salt into 200l of industrial grade isopropanol, stir well and enter electrophoresis tank 2 for 30 minutes of separation. Under the pressure of 0.6MPa, the The flow rate of 80l / h passes through the cation exchange column 3 equipped with strongly acidic D002 large-pore sulfonic acid-based polystyrene resin, the anion-exchange column 4 equipped with strong basic D201 large-pore styrene resin, and then enters the 4A molecular sieve Molecular sieve dryer 5 absorbs and dehydrates, and controls the water content to be less than 90ppm; dehydrates through the resin dryer 6 equipped with super absorbent resin at a constant flow rate of 80l / h, controls the water content to be less than 10ppm, and continues to enter at a flow rate of 80l / h Microfilter 7, with a working pressure of 0.6MPa, removes impurity particles; enters a tetrafluoroethylene-lined four-stage rectification...

Embodiment 2

[0025] refer to figure 1 , at normal temperature and pressure, add 6.0g of ethylenediaminetetraacetic acid disodium salt into 300l of industrial grade isopropanol, stir well and enter electrophoresis tank 2 for 40 minutes of separation. The flow rate of / h passes successively through the cation exchange column 3 equipped with strongly acidic D002 large-aperture sulfonic acid-based polystyrene resin, the anion-exchange column 4 equipped with strongly basic D201 large-aperture styrene resin, and then enters the 4A molecular sieve. Molecular sieve dryer 5 absorbs and dehydrates, and controls the water content to be less than 90ppm; dehydrates through the resin dryer 6 equipped with super absorbent resin at a constant flow rate of 100l / h, controls the water content to be less than 10ppm, and continues to enter the micro at a flow rate of 100l / h Filter 7, the working pressure is 0.6MPa, remove impurity particles; enter the four-stage rectification tower 8 lined with tetrafluoroethy...

Embodiment 3

[0027] refer to figure 1 , at normal temperature and pressure, add 20.0g of ethylenediaminetetraacetic acid disodium salt (EDTA) into 400l of industrial grade isopropanol, stir well and enter electrophoresis tank 2 for 60 minutes of separation, under the pressure of 1.0MPa , pass through the cation exchange column 3 that strongly acidic D002 large-pore diameter sulfonic acid group polystyrene resin is housed, the anion-exchange column 4 that strongly basic D201 large-pore diameter styrene resin is housed with the flow velocity of 150l / h successively, then enter the house that is equipped with Molecular sieve drier 5 of 4A molecular sieve absorbs and dehydrates, and controls the water content to be less than 90ppm; dehydrates through the resin drier 6 equipped with super absorbent resin at a constant flow rate of 150l / h, controls the water content to be less than 10ppm, and continues to flow at 150l / h The flow rate enters the microfilter 7, and the working pressure is 0.6MPa to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com