Food stuffing conveying device

A filling and conveying technology, applied in transportation and packaging, conveyors, conveying bulk materials, etc., can solve the problems of low utilization rate of equipment, increase labor intensity, and low efficiency, reduce labor intensity, facilitate disassembly, and improve economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

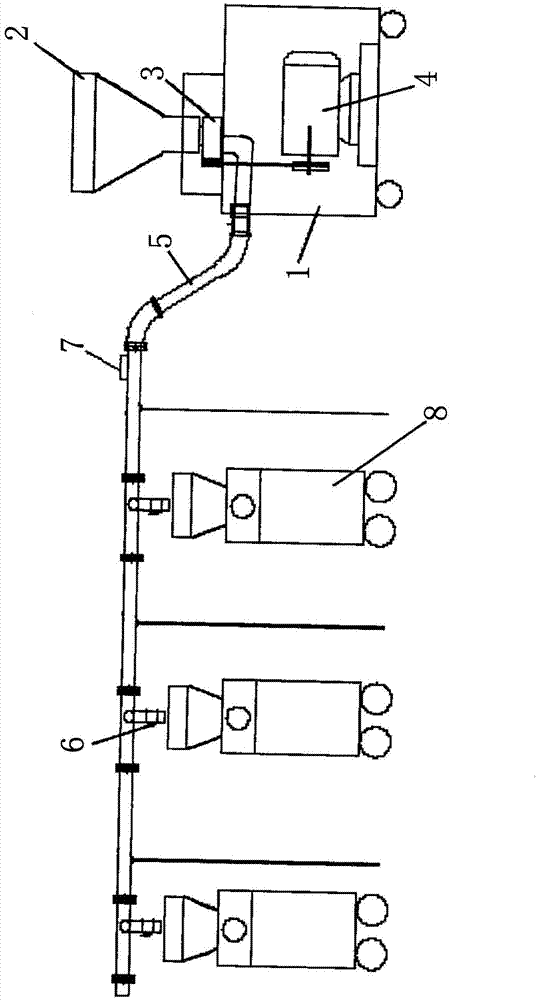

[0009] Such as figure 1 As shown, the present invention is equipped with a hopper 2 on the top of the frame 1, and a feed pump 3 is connected to the lower discharge port of the hopper 2, and the feed pump 3 is connected together with the motor 4 located at the bottom of the frame 1 through a belt. A main discharge pipe 5 is connected to the feed pump 3, and a plurality of branch feed valves 6 are arranged on the main discharge pipe 5, and a pressure sensor 7 is also arranged on the main discharge pipe 5. Through the above settings, food fillings are added to the hopper 2 of the present invention, and the feed pump 3 transports the food fillings to the main discharge pipe 5 under the action of the motor 4, and a plurality of branch feeders on the main discharge pipe 5 are opened. The material valve 6 can supply materials to multiple meatball machines 8 respectively, and the pressure sensor 7 senses the pressure of the filling material in the main discharge pipe 5, which ensures...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com