A kind of formula, preparation method and application of pencil board softener

A softener and pencil board technology, applied in chemical instruments and methods, manufacturing tools, other chemical processes, etc., can solve the problems of unsuitable softening treatment of poplar pencil boards, long chemical treatment period, and uneven heat exposure of wood. , to achieve the effect of small expansion and contraction, straight gas texture and low wood requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

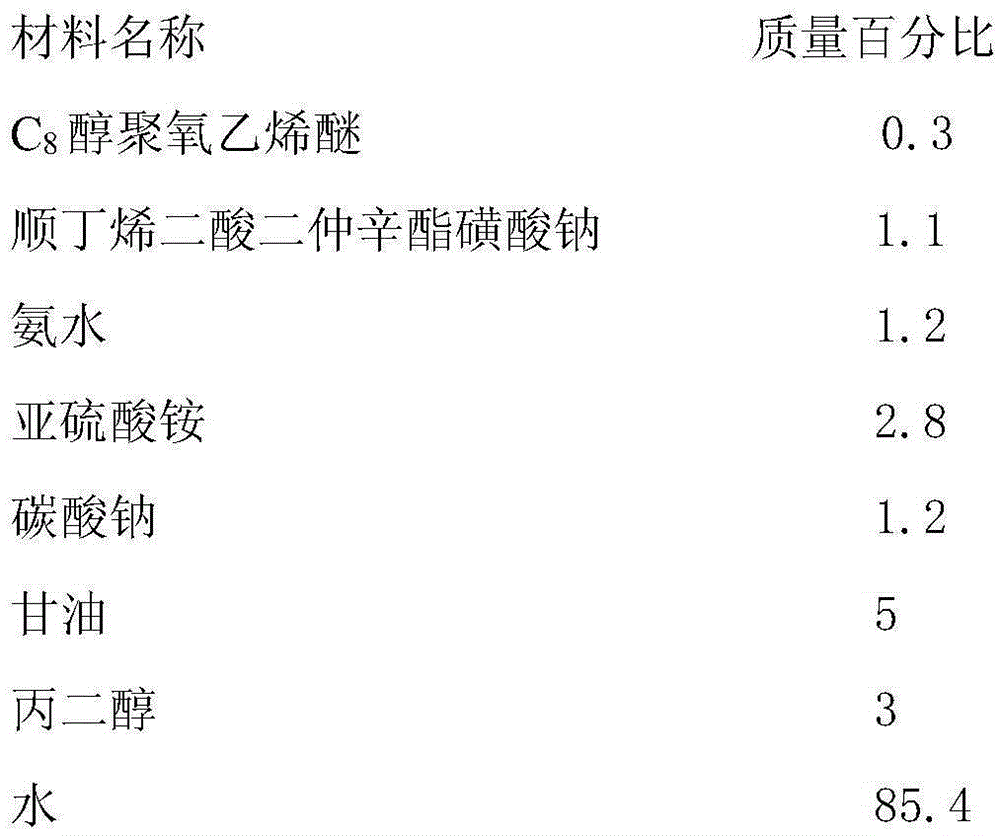

[0019] The specific configuration of medicines and ratios are as follows:

[0020]

[0021] Concrete preparation method: solvent water is placed in container, and part of material urea, sodium sulfite, sodium hydroxide weighed above is added, after dissolving completely, add softener, emulsifier, penetrating agent and protective agent again, obtain transparent liquid.

[0022] Specific implementation of plate processing

[0023] Immerse the poplar wood pencil board (length 183mm*width 73mm*thickness 5mm) into a 0.8% sodium hydroxide solution for 24 hours, take out the pencil board and wash it; then immerse the pencil board in a container containing a pencil board softener for 80 Treat at ℃ for 3 hours; take out the pencil board, rinse it with clean water, and dry it in an oven. The poplar pencil board treated in this way has the characteristics of less resin and lignin content, easy scratching, straight gas texture, fine and uniform structure, moderate soft and hard textu...

Embodiment 2

[0025] A kind of pencil board softener is specifically configured with medicines, and the ratio is as follows:

[0026]

[0027] The specific preparation method is the same as the process in Example 1.

[0028] A kind of concrete application of pencil board softening agent: immerse poplar wood pencil board (length 183mm*width 73mm*thickness 5mm) in mass fraction and be soaked in 0.8% sodium hydroxide solution for 24h, take out pencil board and clean; Immerse in a container containing a pencil board softener and treat at 60°C for 2 hours; take out the pencil board, rinse it with clean water, and dry it in an oven. The poplar pencil board treated in this way has the characteristics of less resin and lignin content, easy scratching, straight gas texture, fine and uniform structure, moderate soft and hard texture, microstrip brittleness, and small expansion and contraction. The softening fluid can treat the pencil board several times in a row.

Embodiment 3

[0030] A kind of pencil board softener is specifically configured with medicines, and the ratio is as follows:

[0031]

[0032] The specific preparation method is the same as the process in Example 1.

[0033] A kind of concrete application of pencil board softening agent: immerse poplar wood pencil board (length 183mm*width 73mm*thickness 5mm) in mass fraction and be soaked in 0.8% sodium hydroxide solution for 24h, take out pencil board and clean; Immerse in a container containing a pencil board softener and treat at 60°C for 2 hours; take out the pencil board, rinse it with clean water, and dry it in an oven. The poplar pencil board treated in this way has the characteristics of less resin and lignin content, easy scratching, straight gas texture, fine and uniform structure, moderate soft and hard texture, microstrip brittleness, and small expansion and contraction. The softening fluid can treat the pencil board several times in a row.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com