Column longitudinal movement surface grinder

A technology for vertically moving and surface grinding machines, which is applied in the direction of grinding machines, machine tools suitable for grinding the plane of workpieces, and parts of grinding machine tools, etc. problems, to achieve the effect of no power loss, avoid processing errors, and realize automatic error correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

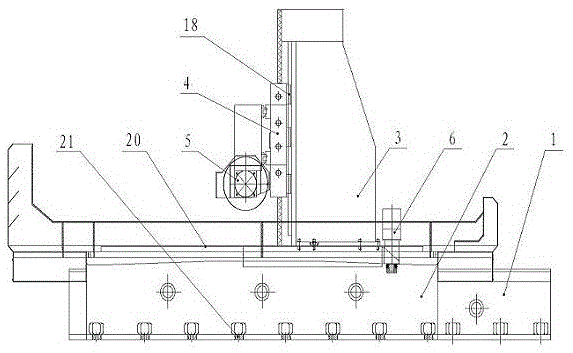

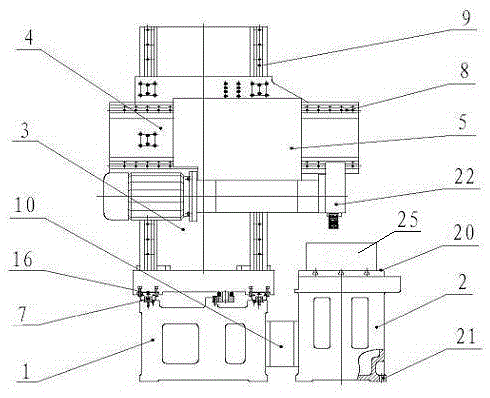

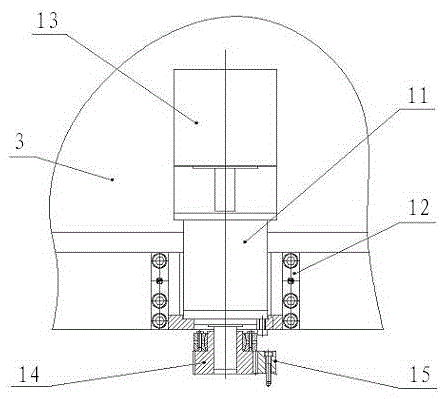

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0022] see figure 1 , figure 2 , The present embodiment is a surface grinder with column longitudinal movement, which is composed of two parts, the front table 2 and the rear bed 1, and the front table 2 and the rear bed 1 are arranged in parallel. The front workbench 2 base is provided with fixed installation hole 21, directly installs on the ground, and utilizes anchor bolts to adjust the levelness. The front workbench 2 and the rear bed 1 are connected into one body through a connecting block 10 .

[0023] Among them, the rear bed 1 is provided with two parallel longitudinal guide rails 7, and a stable guiding mechanism is arranged between the two longitudinal guide rails 7, and the stable guiding mechanism makes the column 3 and the rear bed 1 easy to cooperate during assembly and relative opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com