Efficient ultrasonic metal surface machining tool

A metal surface and machining tool technology, applied in the field of ultrasonic machining, can solve the problems of inability to use, low machining efficiency, poor effect, etc., and achieve the effect of reducing the overall volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

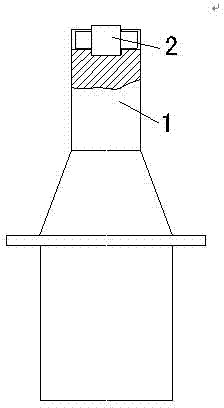

[0022] Such as figure 1 As shown, the ultrasonic machining tool of this embodiment includes a horn 1 and a tool head 2. The tool head 2 is in the shape of a stepped shaft with small ends and a large middle part. The two ends are positioning parts, and the middle is a processing part. The diameter is smaller than the processing part. The front part of the horn 1 is provided with a positioning installation groove for installing the tool head 2, the structure of the positioning installation groove is adapted to the tool head 2, and the size of the middle part is larger than that of both ends. The tool head 2 is put into the positioning installation groove by the front end of the horn 1, and the bottom edge of the middle processing part is in contact with the horn 1. In this way, when in use, the tool head 2 is always in contact with the horn 1, and there is no need to adjust the gap between the tool head 2 and the horn 1.

[0023] The horn 1 directly drives the intermediate pro...

Embodiment 2

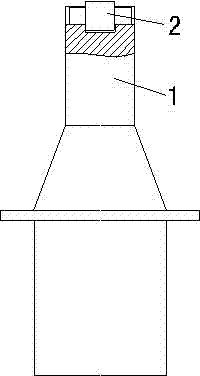

[0025] Such as figure 2 As shown, the difference between the ultrasonic machining tool of this embodiment and Embodiment 1 is that the bottom edge of the positioning part at both ends of the tool head 2 is in contact with the horn 1 , while the middle processing part is not in contact with the horn 1 . The horn 1 drives the middle processing part to vibrate at high frequency through the positioning parts at both ends of the tool head 2, so as to realize ultrasonic processing on the surface of the workpiece.

Embodiment 3

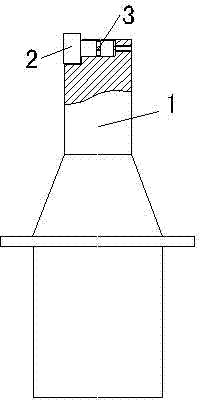

[0027] Such as image 3 As shown, the ultrasonic machining tool in this embodiment includes a horn 1 and a tool head 2 . The front end of the horn 1 is provided with a tool head installation hole perpendicular to the axis of the horn 1, and the tool head installation hole may be a blind hole or a through hole. The side of the tool head mounting hole is provided with a limit pin hole, and a limit pin 3 is installed in the limit pin hole. The tool head 2 is a T-shaped stepped shaft structure, one end is a positioning part, and the other end is a processing part, and the diameter of the positioning part is smaller than that of the processing part. The positioning part is provided with a circumferential limit groove, which realizes the axial positioning of the tool head 2 in the tool head installation hole by cooperating with the limit pin 3, so that the tool head 2 can only rotate but cannot move axially . The processed part of the tool head 2 is outside the mounting hole of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com