One-step forming combined tool of curved surface for plastic boards

A technology of combining cutting tools and curved surfaces, applied in the field of non-standard cutting tools, which can solve problems such as difficult appearance and inability to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

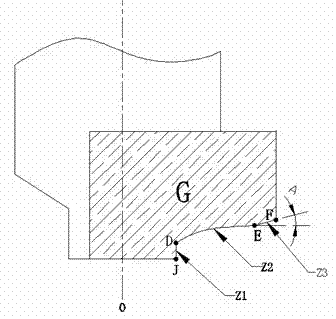

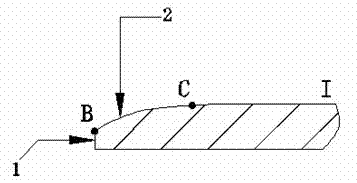

[0017] Example: When the thickness of the cut product is 2mm, the non-curved part L 1 The total height is 1.2mm, the diameter of the main cutting edge of the tool is ?2mm, the diameter of the handle is ?6mm, and the length of the main cutting edge Z1 is generally selected as L Z1 =1.25mm (the tool will penetrate the protective film to a certain depth, that is, the depth in the Y direction from the bottom plane of the cutting piece as a reference, the range is 0.05~0.1mm), the arc cutting edge Z2 is completely in line with the arc surface of the workpiece 2 contour lines coincide. If the angle A formed between the safety bevel Z3 and the horizontal plane is 4° (avoidance transition angle), the purpose is to process a smoother surface without tool marks; the starting point B of the arc surface of the workpiece to be processed is horizontal to the end point C the distance L BC 4mm; the vertical distance H between the starting point B of the arc surface of the workpiece and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com