Glue injection device of battery

A technology of glue injection device and battery, which is applied to primary batteries, equipment for manufacturing primary batteries, and battery assembly machines, etc., can solve the problem of unrealistically coating the bottom of separator paper, affecting the performance of battery composition, and increasing the amount of glue injected, etc. problems, to achieve the effect of ensuring electrical performance, avoiding performance impact, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0027] Due to the poor fluidity of the glue, the uneven coating on the bottom of the separator paper, and if the injection volume of the glue is increased to ensure uniform coating, the glue on the bottom of the battery steel case (the bottom of the separator paper) will be too thick, which will affect the volume and other performance, reducing safety and working life. Therefore, it is necessary to design a more reasonable battery glue injection device that can evenly coat the glue on the bottom of the separator paper.

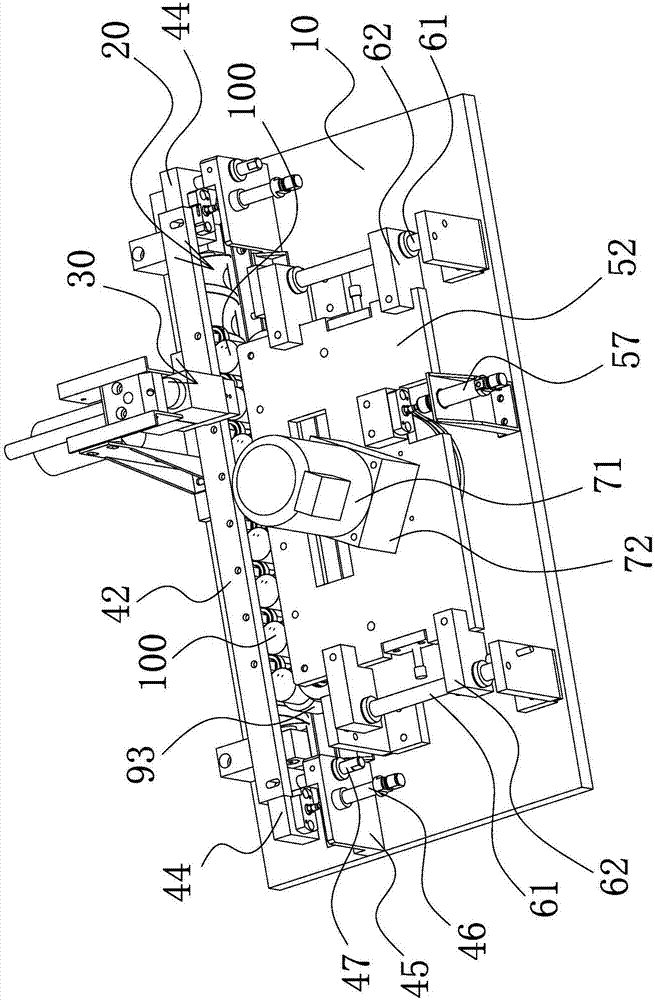

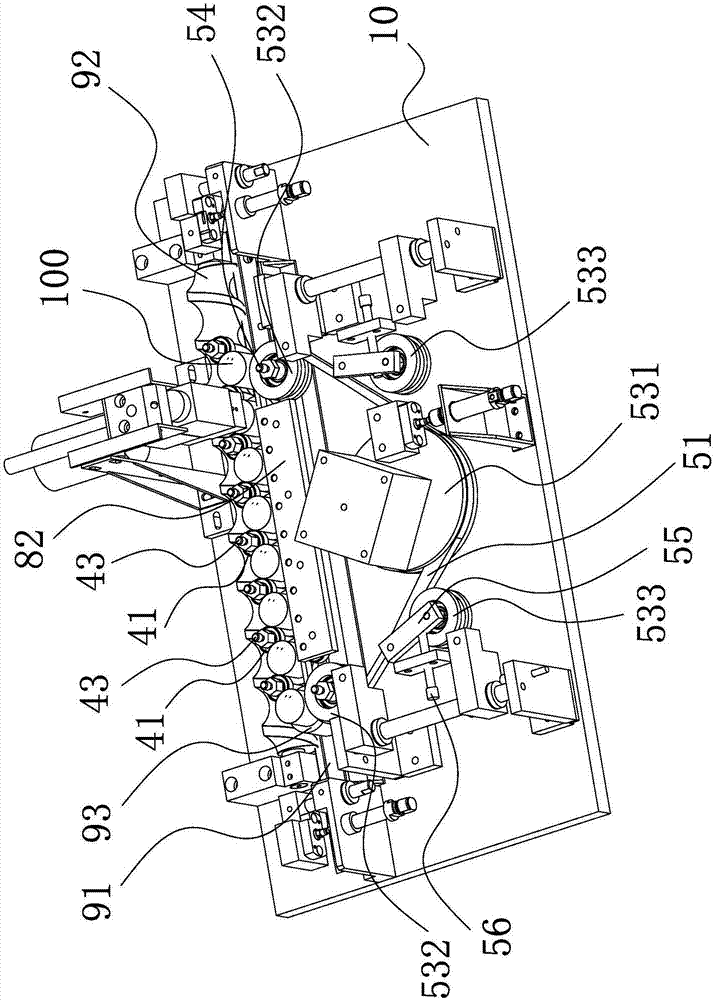

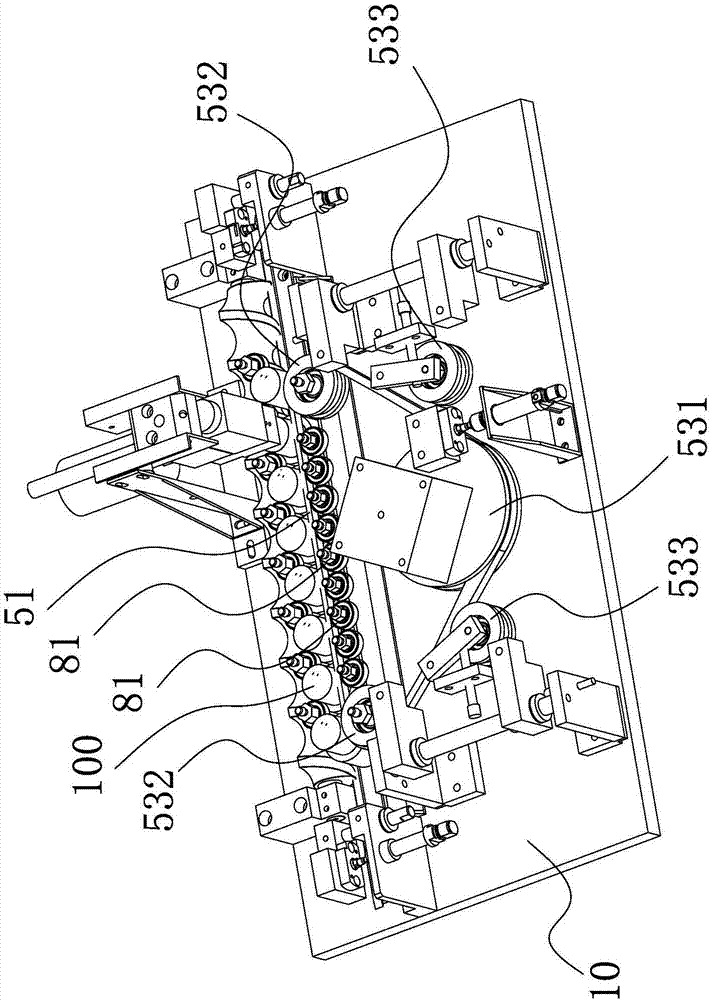

[0028] Combine below Figure 1 to Figure 3 The technical solution provided by the present invention is described in more detail.

[0029] Such as Figure 1 to Figure 3 As shown, the battery glue injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com