Full-automatic intelligent steel wire handle forming machine

A fully automatic, molding machine technology, applied in other home appliances, home appliances, applications, etc., can solve problems such as inability to intelligently control, low efficiency, and difficult to guarantee product quality, to reduce the quantity and labor, reduce labor costs, The effect of coating quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

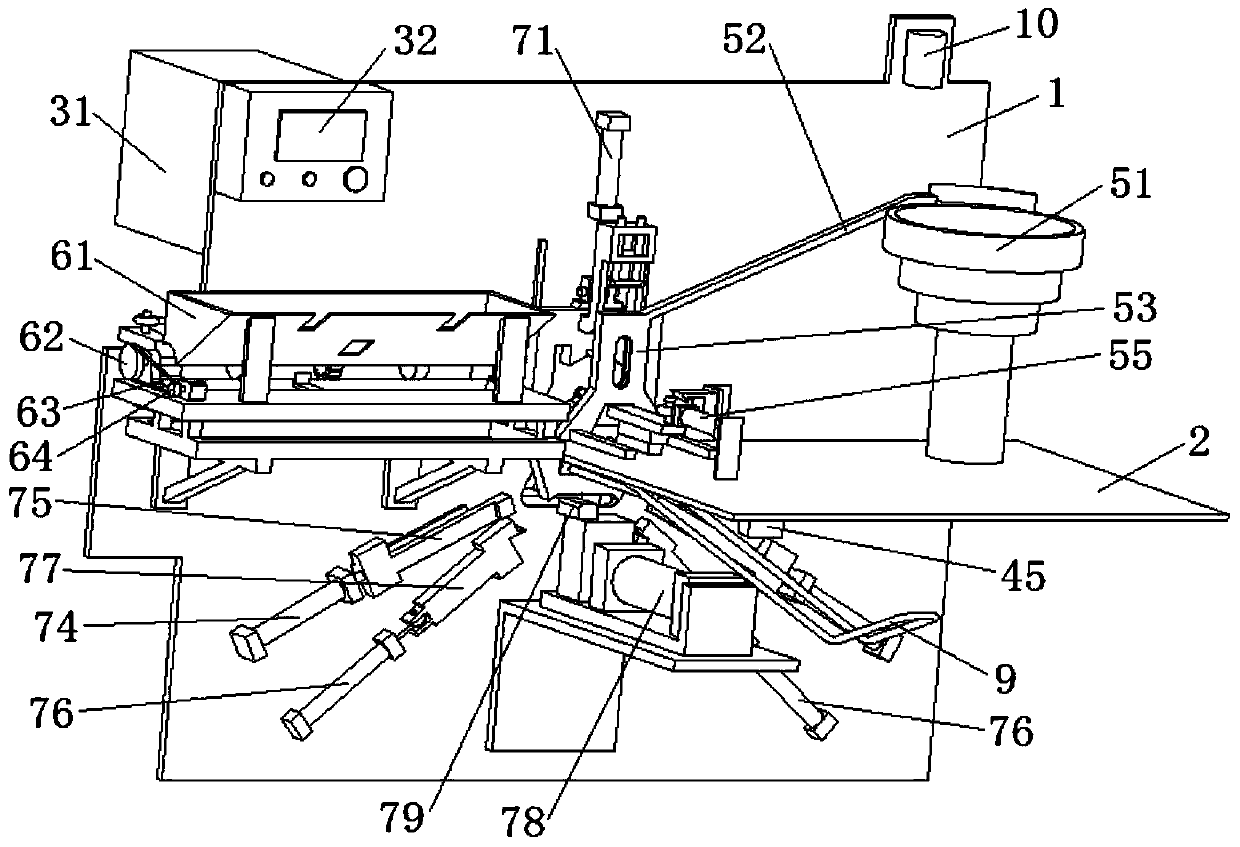

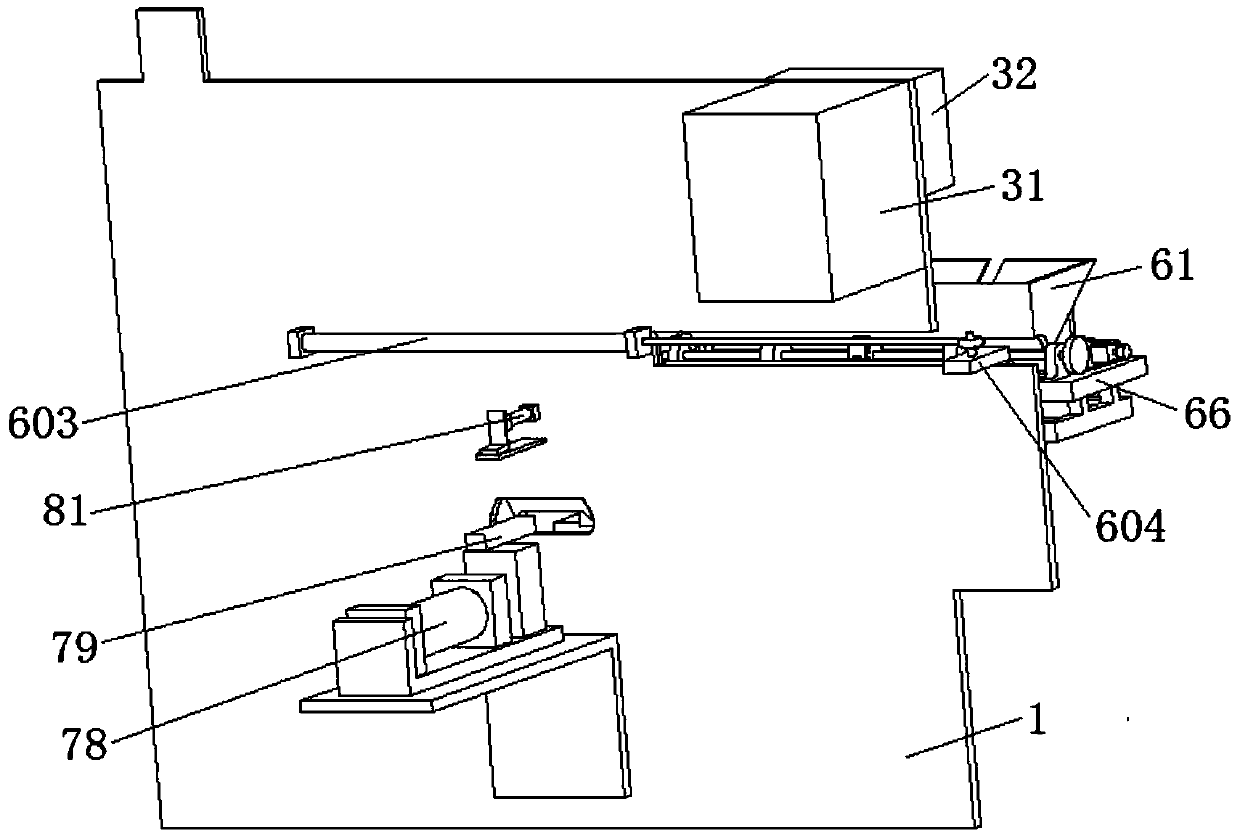

[0041] to combine Figure 1 to Figure 7 , a kind of fully automatic intelligent steel wire handle forming machine of the present embodiment comprises frame 1, workbench 2, handle tube feeding device, steel wire feeding device, forming device, unloading device, PLC control device and detection device, wherein , The forming device, unloading device, steel wire feeding device and PLC control device are installed on the frame 1, and the handle tube feeding device is installed on the workbench 2. Such as image 3 As shown, the molding device includes a movable mold 72, a movable mold driver 71, a fixed mold 73, a pressing member 75, a pressing driver 74, a first bending member 77, a first bending driver 76, a second bending member 79 and The second bending driver 78, the fixed mold 73 is fixedly installed on the frame 1, the movable mold 72 is installed on the slide rail above the fixed mold 73, and is connected with the movable mold driver 71, and the two sides of the fixed mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com