Method for preparing ZnFeCr hydrotalcite photocatalyst

A catalyst, stone light technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as high cost and excitation wavelength limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

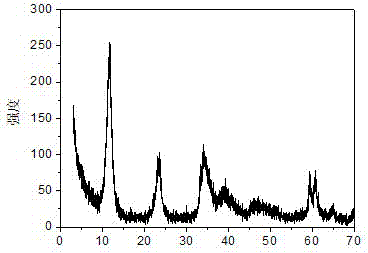

[0022] The XRD spectrum of the prepared ZnFeCr hydrotalcite is shown in the attached figure 1 . It can be seen that the prepared photocatalyst has typical hydrotalcite characteristic diffraction peaks.

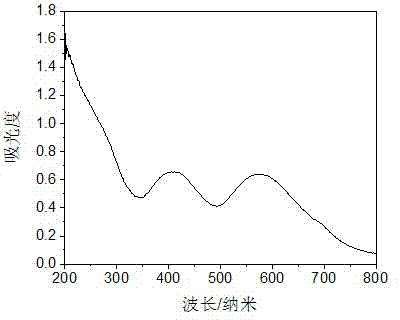

[0023] The UV-Vis spectrogram of the prepared ZnFeCr hydrotalcite is shown in the attached figure 2 . It can be seen that the prepared photocatalyst has visible light response.

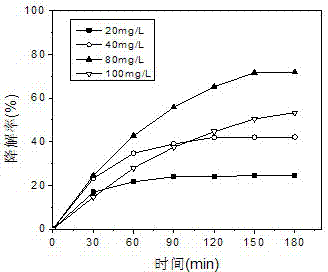

[0024] A 500 W long-arc xenon lamp (wavelength > 400 nm) is used as a simulated visible light source. The effective length of the visible light source lamp tube is 6 cm, and the light intensity is 1.5 kW / m 2 . The xenon lamp is placed in the quartz sleeve, and cooling water is passed through the interlayer of the sleeve to keep the reaction solution at a constant temperature. At 25 °C, 150 ml of methyl orange solutions of different concentrations and 1.25 g / L catalyst were added into the beaker. Before photocatalysis, stir in the dark for 2 h to allow the catalyst adsorption-dissociation to rea...

Embodiment 2

[0026] When the initial concentration of methyl orange is 30 mg / L, different catalyst concentrations are used to photocatalytically degrade methyl orange. Other photocatalytic performance test steps are the same as in Example 1. The test results are shown in the attached image 3 .

[0027] attached image 3 The results show that the prepared ZnFeCr hydrotalcite photocatalyst has a good methyl orange degradation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com