a steam separator

A technology of steam-water separator and steam-water separation, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of low separation efficiency of steam-water separation reheater, steam quality not meeting design requirements, limited separation space, etc. problems, to achieve the best steam-water separation efficiency, complete steam-water separation, and steam quality up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

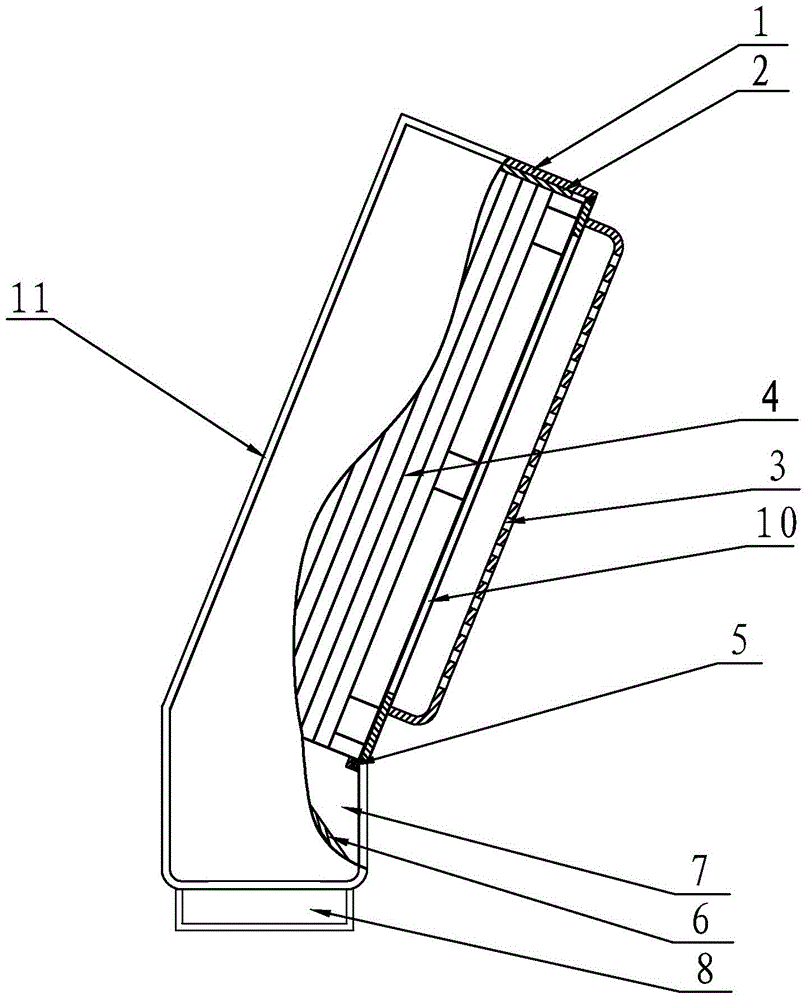

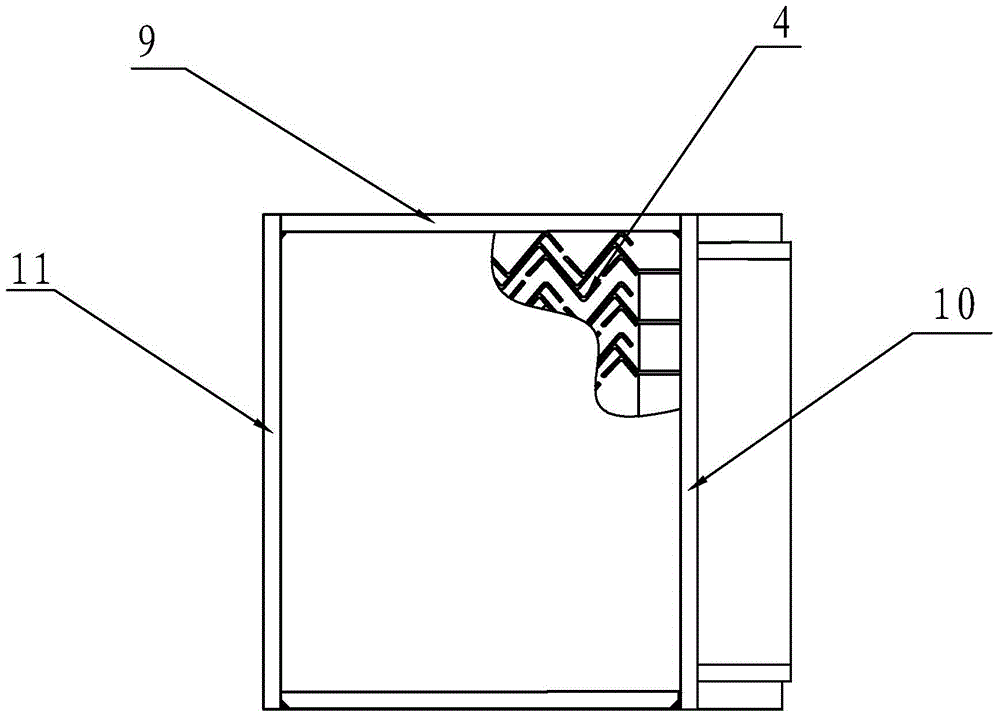

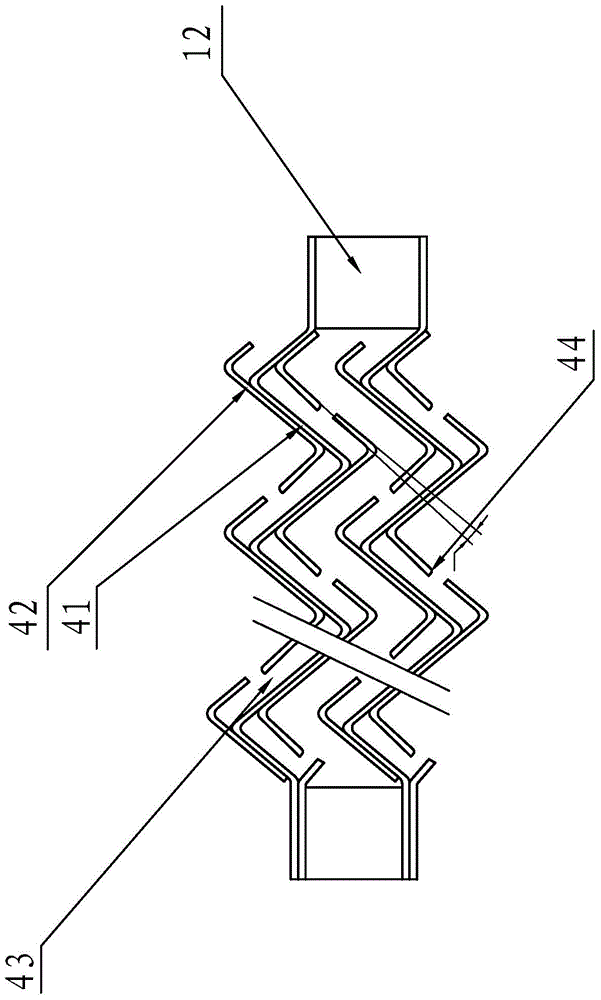

[0019] refer to Figure 1 ~ Figure 3 , the present invention is a steam-water separator, comprising a porous plate 3 and a steam-water separation cavity for receiving the wet steam entered by the porous plate 3, a corrugated plate assembly 4 is arranged in the steam-water separation cavity, the steam-water separation cavity is arranged obliquely, and the corrugated plate Component 4 includes several corrugated main boards 41 arranged in the steam-water separation cavity and spacer plates 12 installed at both ends of adjacent corrugated main boards 41 for spacing adjacent corrugated main boards 41, and two adjacent corrugated main boards 41 form a The steam channel, the bottom of the steam-water separation chamber is provided with a sump 7 and a drain 8 below the sump 7 .

[0020] This steam-water separator passes the wet steam through the corrugated plate assembly 4, and separates the wet steam from steam and water through several corrugated main boards 41 in the corrugated pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com