Tea dampening machine

A moisture-rejuvenating machine and tea technology, applied in the direction of tea treatment before extraction, can solve the problems of tea dispersion, unsuitable for tea re-moisturizing, and can not achieve a moderate stacking effect, etc., and achieve the effect of being conducive to transformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

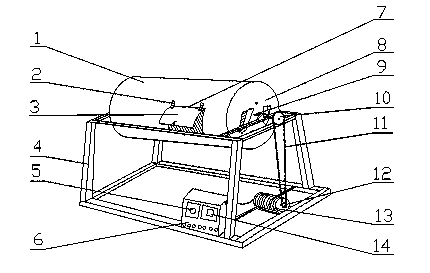

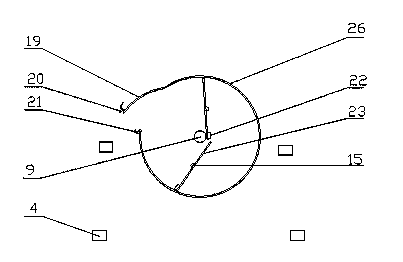

[0022] A tea moisture rejuvenating machine, comprising a bracket (4), a drum (1), a central shaft (9), a transmission system, and a control box (6); the drum (1) consists of a cylindrical drum side wall (26) fixed together It is composed of the cylinder cover (8), the inner diameter of the cylinder side wall (26) is 60cm, and the length is 120cm; the central axis (9) passes through the center of the cylinder cover (8) at both ends of the cylinder (1) and connects with the cylinder cover (8) fixed, the transmission system drives the drum (1) to rotate through the central shaft (9).

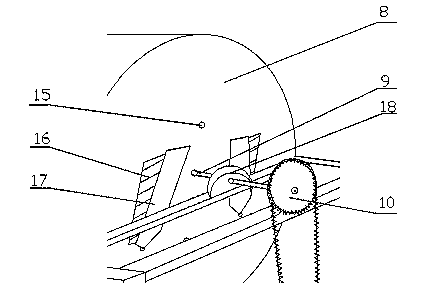

[0023] The transmission system includes a DC motor (13), a power sprocket (12), a bearing (25), a bearing seat (18), a central shaft sprocket (10), and a chain (11); the transmission system and the central shaft (9) The way is: the two ends of the central shaft (9) are installed on the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com