Gas drying device for micro-coulometry total-chlorine analyzer

A gas drying and analyzer technology, which is applied to the microcoulometric determination of total chlorine content in petrochemical products, and the field of gas drying devices for microcoulomb total chlorine analyzers, which can solve the problem of low detection results, easy burns to operators, peaks shape tailing and other problems, to achieve safe and reliable operation, good drying effect and good air tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

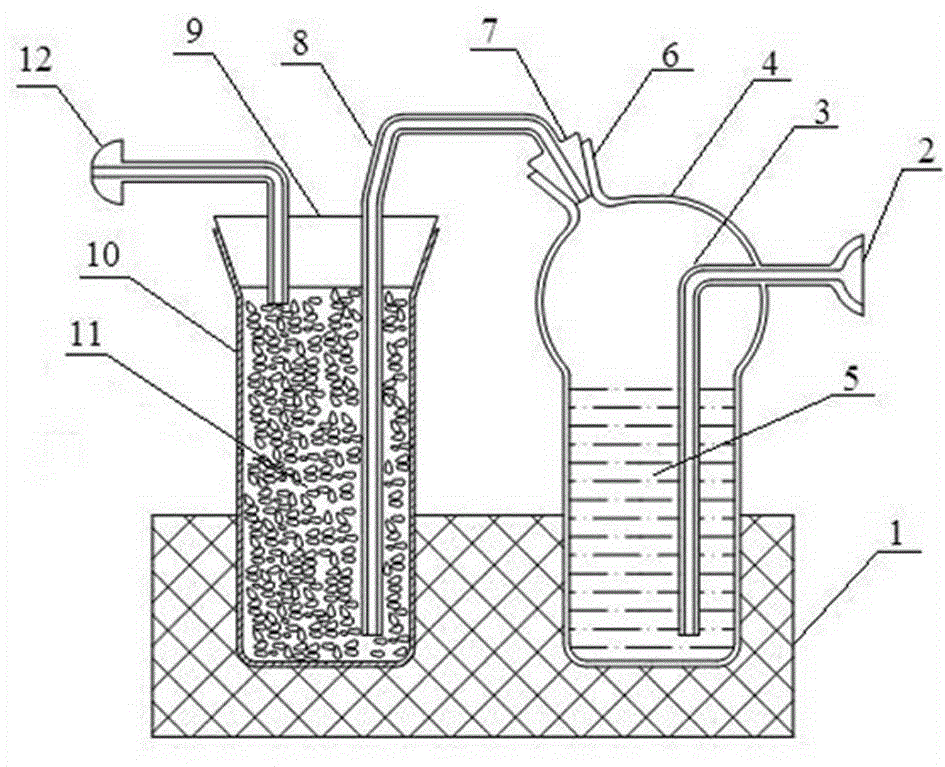

[0013] see figure 1 , The drying device of the present invention is composed of a concentrated sulfuric acid drying cylinder and a magnesium perchlorate drying tube connected in series, and is fixed by a fixed base 1 . Concentrated sulfuric acid drying cylinder is composed of inlet pipe 3, cylinder body 4, and air outlet 6. Concentrated sulfuric acid 5 is filled in the cylinder body, and its weight percentage concentration is 98%. The magnesium perchlorate drying pipe is composed of inlet pipe 8, rubber plug 9, pipe 10, the outlet pipe 12 is formed, and the magnesium perchlorate 11 is adorned in the pipe body.

[0014] In the present embodiment, the total height of the concentrated sulfuric acid drying cylinder body 4 is 10cm, the upper part of the cylinder body is spherical, the lower part is cylindrical, the height of the columnar part is 6cm, and the diameter is 3cm. The liquid level of the concentrated sulfuric acid 5 in the cylinder body is The height is 5cm. Intake pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com