Method for field detection on structural adhesive gap between glass panel and secondary frame of existing hidden frame curtain wall

A glass panel and on-site detection technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as heavy workload, limited use range, and normal use of buildings, so as to avoid normal use, The effect of simple operation and avoiding complicated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

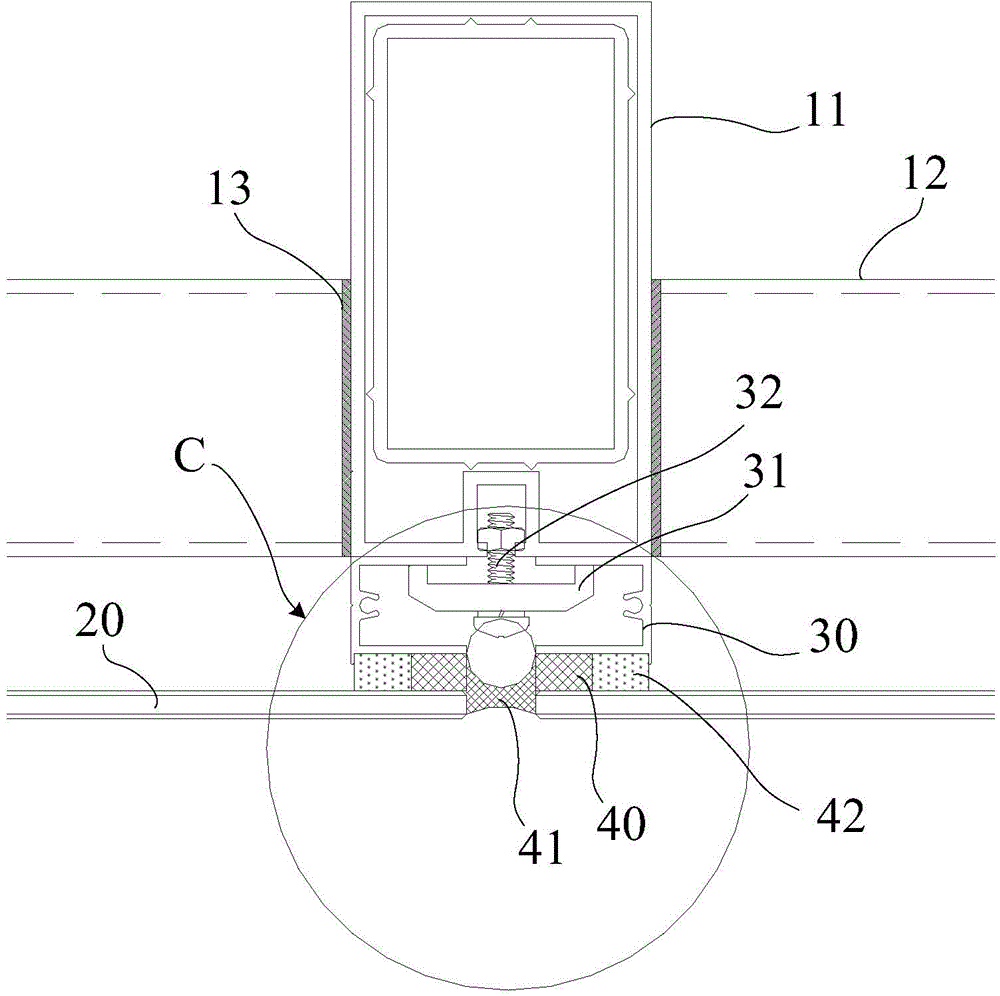

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

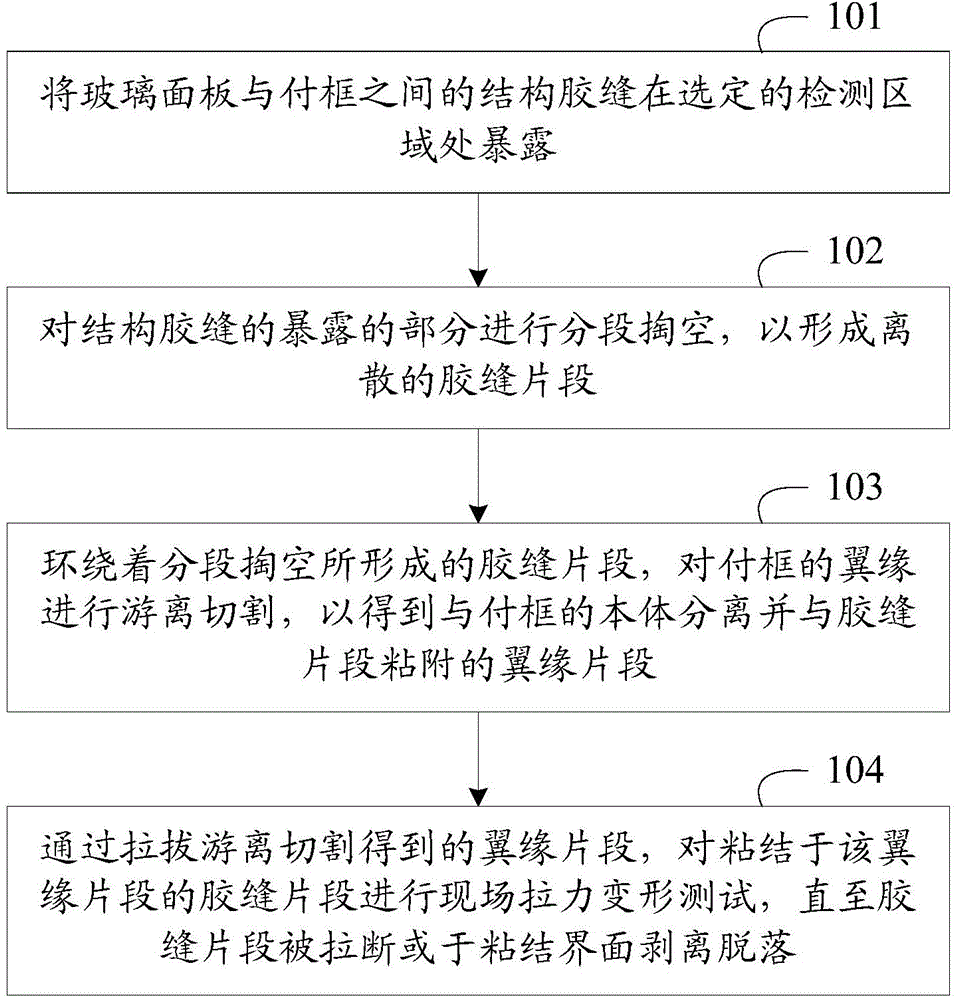

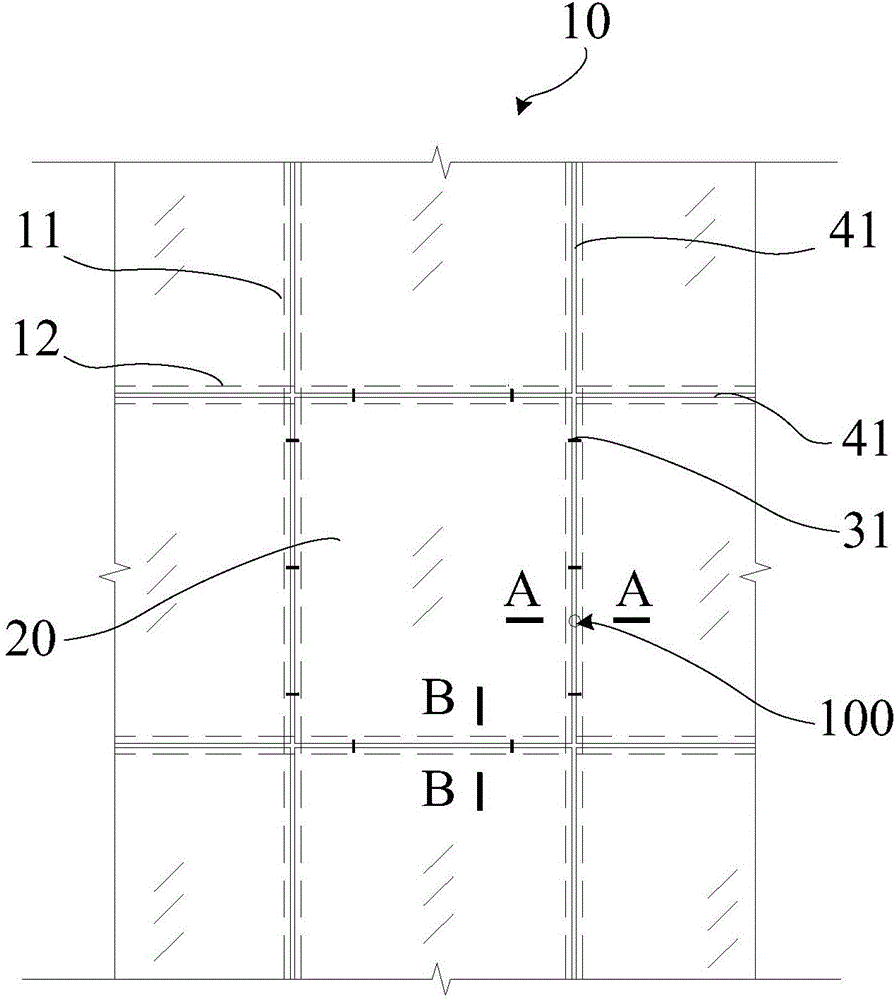

[0033] figure 1 It is a schematic flowchart of a method for on-site detection of structural glue joints of glass panel sub-frames of existing hidden frame curtain walls in an embodiment of the present invention. Such as figure 1 As shown, in the embodiment of the present invention, the method for on-site detection of the structural glue seam of the glass panel sub-frame of the existing hidden frame curtain wall includes:

[0034] Step 101, exposing the structural glue joint between the glass panel and the auxiliary frame at a selected detection area. In practical applications, for the case where the structural rubber joint is covered and protected by double-sided sealant, this step can expose the structural rubber joint in the detection area by removi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com