An Encoder Detection System of a Tower Pumping Unit

A tower pumping unit and detection system technology, applied in the direction of instruments, etc., can solve the problems of high concealment, potential safety hazards, no positioning means, etc., and achieve the effect of simple display interface, accurate state judgment and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

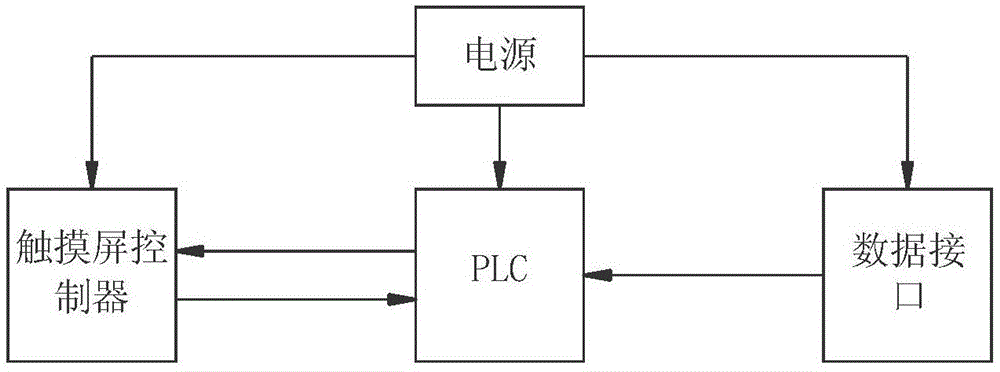

[0017] Example: see figure 1 , a tower type pumping unit encoder detection system, including PLC, touch screen controller, power supply, and cables connected to the pumping unit encoder, the PLC is provided with four high-speed acquisition ports HSC00 to HCS03, through high-speed The acquisition port performs pulse data acquisition for each phase of the encoders A, B, and Z. The high-speed acquisition port is connected to the cable of the pumping unit encoder. The existing tower pumping unit encoders are equipped with cables connected to the ground. , by designing the data interface on the cable, and connecting the data line to the high-speed acquisition port for data acquisition, it avoids the need for professional and technical personnel to climb to the tower and then open the back cover of the pumping unit encoder in the current operation process, and then use an oscilloscope to detect The working process simplifies the operation process and improves the work efficiency and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com