High altitude spherical net rack splicing method based on large gymnasium frame continuous beam

A network frame and ball-shaped technology, which is applied in the field of high-altitude ball-shaped network frame splicing, can solve the problems of large site, long construction period, and affecting the simultaneous construction of the lower part of the network frame, so as to shorten the construction period, occupy a small space on the site, and shorten the overall The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0023] A high-altitude spherical grid splicing method based on the continuous beam of the frame of a large venue, the steps are as follows:

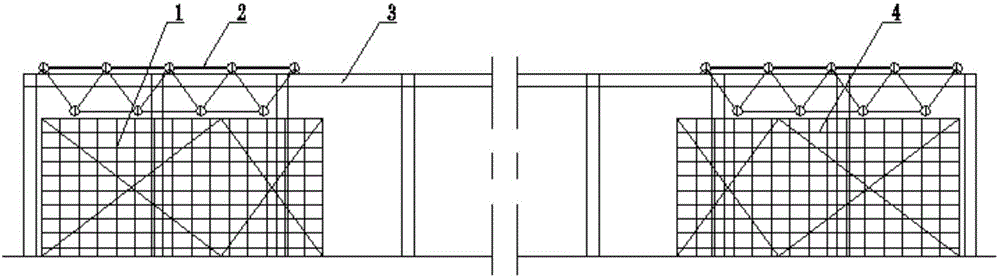

[0024] (1) Build the left installation platform 1 and the right installation platform 4 under the two ends of the continuous beam 3 of the frame of the large venue respectively;

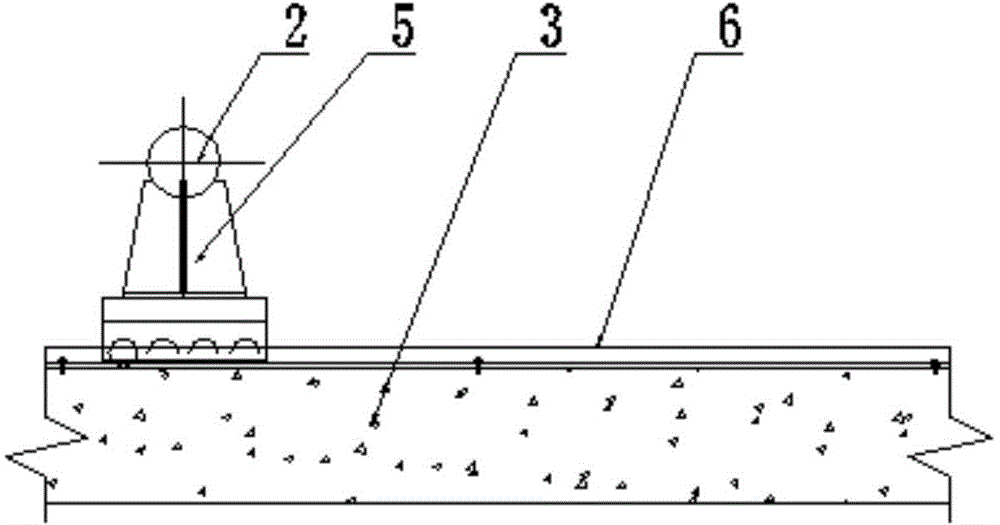

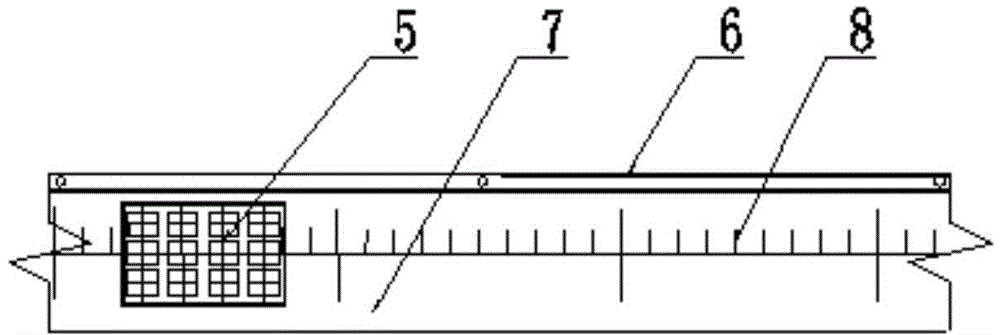

[0025] (2) Install the slideway 7 on the continuous beam of the frame of the large-scale venue, and slide and install the moving trolley 5 of the grid frame at both ends of the slideway; pop up the deflection correction axis 8 of the grid sliding track on the continuous beam of the large-scale venue frame; The side-slip limiting angle steel 6 is respectively fixed on the continuous beams of the large venue frame on both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com