Closure section steel shell of turning continuous beam

A technology of closing section and swivel, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of the superiority of swivel construction and the greater impact of closing section construction, and achieve the effect of improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in combination with specific embodiments.

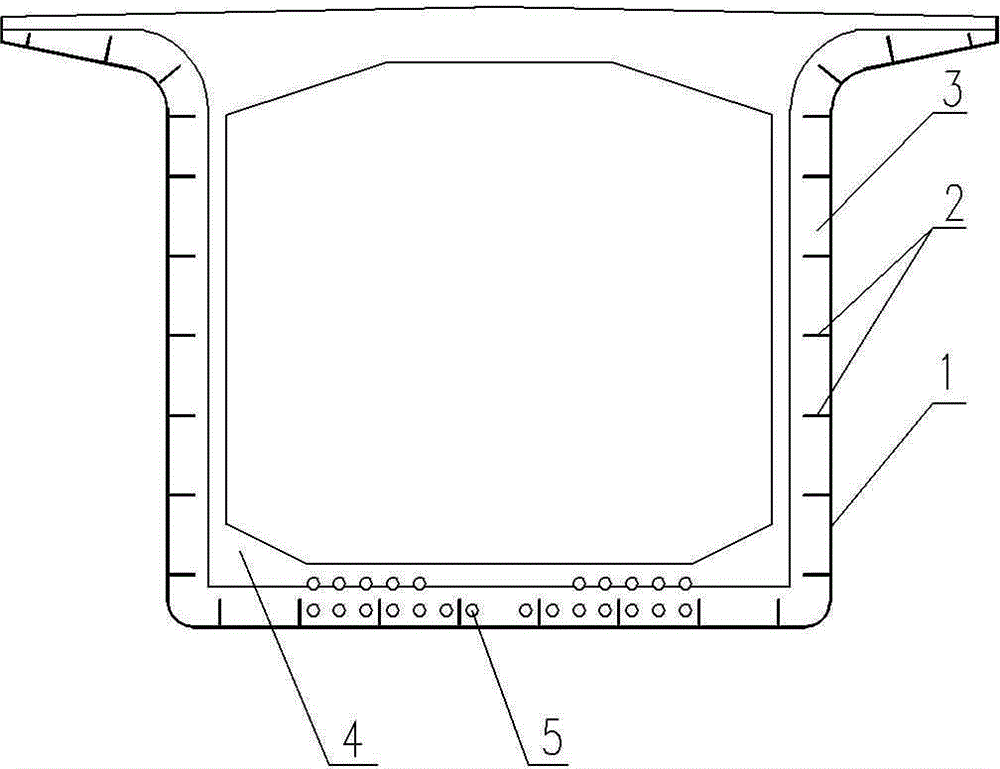

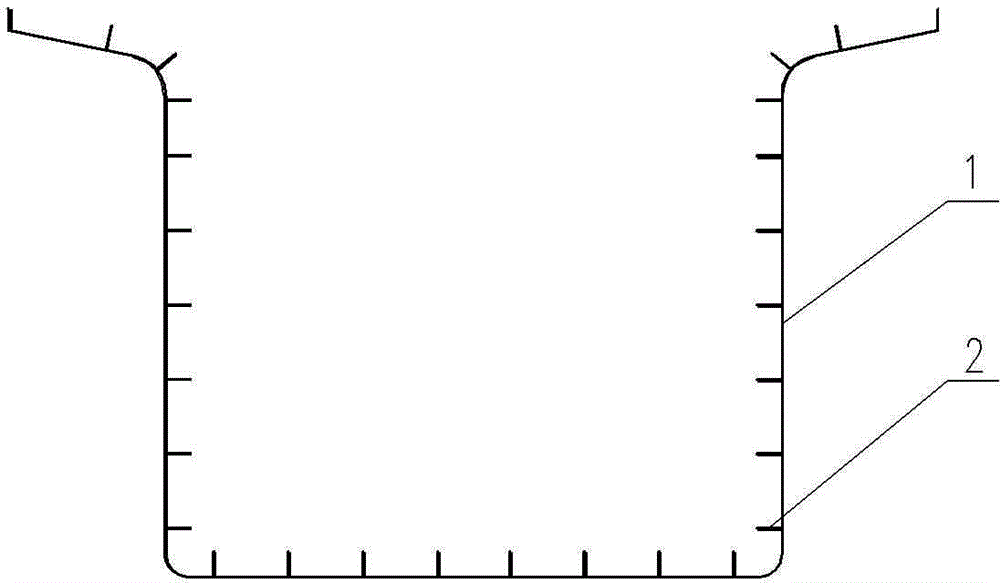

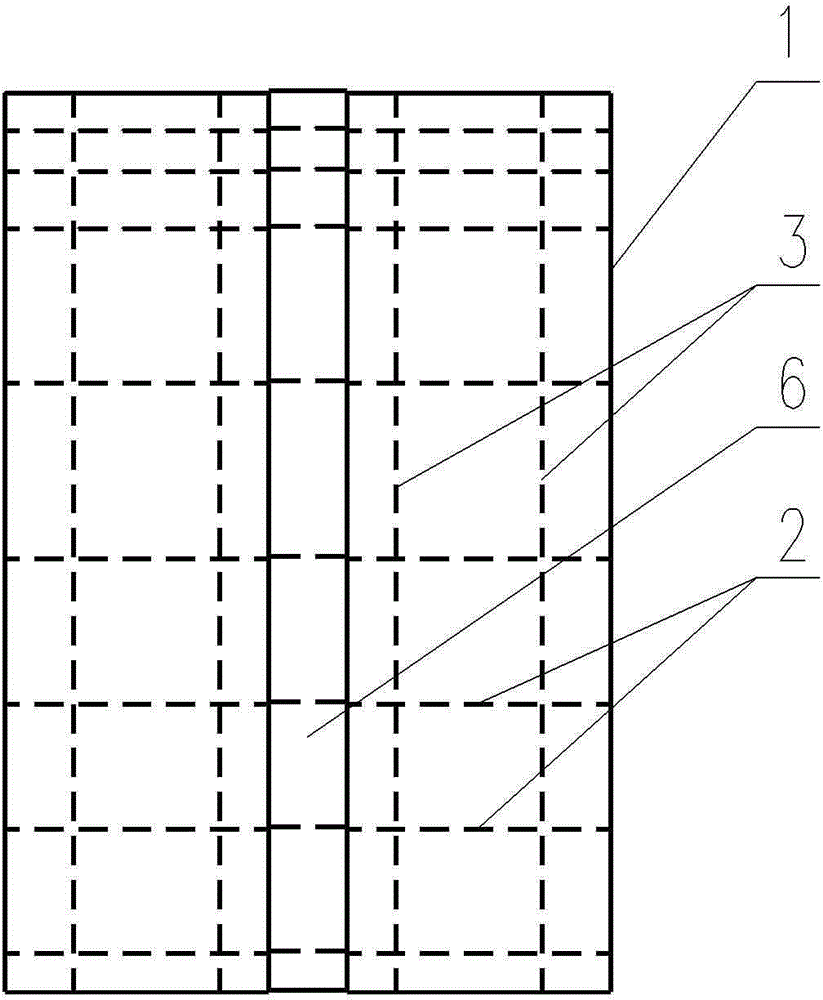

[0017] The present invention relates to a steel shell of a continuous beam with a rotating body, which is provided with a shell 1 with the same shape as the external surface of the beam, and is connected to the end of the beam body 4 of the continuous beam with a rotating body, see figure 1 and figure 2 The housing 1 includes a bottom plate and side plates protruding upwards on both sides of the bottom plate, and the shape of the end part is also the same as that of the beam body wing. The longitudinal width of the casing 1 can be adjusted according to the needs of the working space. The inner wall of the housing 1 is welded with a transverse partition 3 perpendicular to the bottom and side plates of the housing 1, and the transverse partition 3 is a bent strip. The quantity of diaphragm 3 can be adjusted according to the longitudinal width of housing 1, as image 3 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com