Preparation method of pearl fleece breathable fiber

A breathable fiber and pearl fleece technology, applied in fiber treatment, melt spinning, melting of filament raw materials, etc., can solve the problems of urgent additional properties of conventional polyester fibers, improper use of man-made fiber fabrics, damage of man-made fiber fabrics, etc. Achieve good hand feeling, improve wearing comfort, and improve air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

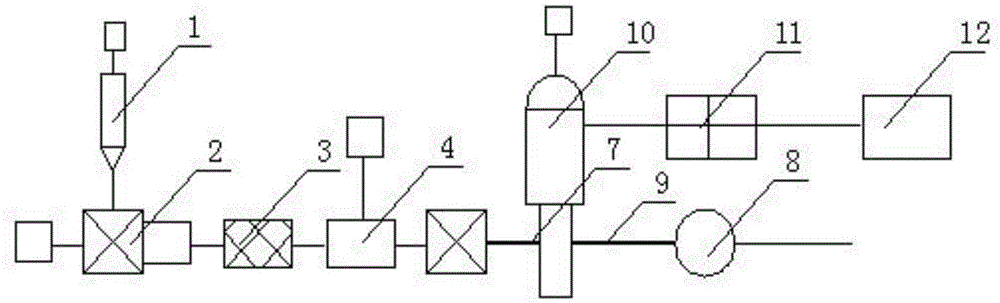

[0021] Such as figure 1 As shown, in the preparation method of the pearl fleece breathable fiber described in this example, the pearl functional masterbatch is placed in the masterbatch dryer 1 to dry for 13 hours, the water content of the masterbatch is 28ppm, and the drying temperature of the masterbatch is 130°C. The masterbatch is extruded after melting through the screw extruder 2, and the temperature of each section of the extruder is divided into 277°C, 282°C, 288°C, 292°C, 292°C, 292°C, and then passes through the melt pre-filter 3 The molten masterbatch is sent into the metering injection pump 4 through the delivery pipeline, and the masterbatch melt is sent into the dynamic mixing agitator 10 through the delivery pipeline 7 to mix with the polyester melt after the metering. The speed of the dynamic mixing agitator 10 is 60r / min. The mixed polyester melt is further mixed uniformly through the static mixer 11; the uniformly mixed polyester melt is passed through the po...

Embodiment 2

[0025] Such as figure 1 As shown, in the preparation method of the pearl fleece breathable fiber described in this example, the pearl functional masterbatch is placed in the masterbatch dryer 1 to dry for 14 hours, the water content of the masterbatch is 29ppm, and the drying temperature of the masterbatch is 130°C. The masterbatch is extruded after being melted by the screw extruder 2, and the temperature of each section of the extruder is divided into 278°C, 283°C, 289°C, 293°C, 293°C, 293°C, and then passed through the melt pre-filter 3 The molten masterbatch is sent into the metering injection pump 4 through the delivery pipeline, and the masterbatch melt is sent into the dynamic mixing agitator 10 through the delivery pipeline 7 to mix with the polyester melt after the metering, and the speed of the dynamic mixing agitator 10 is 63r / min. The mixed polyester melt is further mixed uniformly through the static mixer 11; the uniformly mixed polyester melt is passed through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation of linear density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com