Anti-interference low-temperature curing catalyst for powder paint and preparation method thereof

A curing catalyst and powder coating technology, applied in powder coatings, coatings, etc., can solve the problems of high temperature curing of powder coatings, increase of production costs of enterprises, waste of energy, etc., to achieve sensitive mixing control, improve quality, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

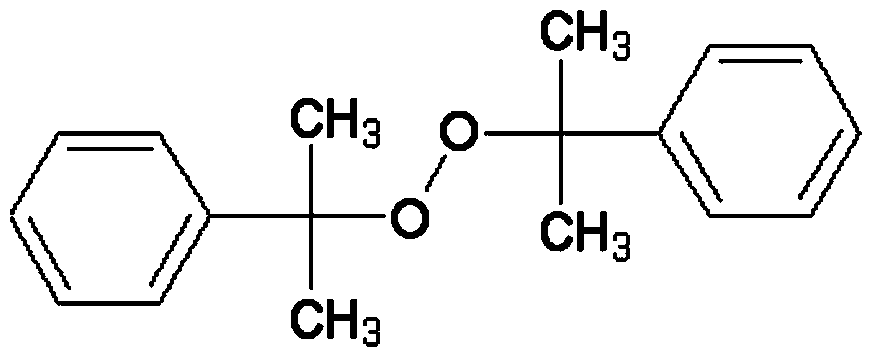

Image

Examples

Embodiment 1

[0038] An anti-interference low-temperature curing catalyst for powder coatings, its raw material components and parts by weight are as follows:

[0039]

[0040] The above-mentioned anti-interference low-temperature curing catalyst for powder coatings can be prepared by twin-screw molten solid phase slurry addition polymerization, and its specific preparation steps are as follows:

[0041] (1) The process parameters of the extrusion equipment are adjusted in place and are in a state of sensitive self-control;

[0042] The temperature of the first, second, third and fourth stages is controlled within the set range: the temperature of the first stage is 0-40°C, the temperature of the second stage is 150-180°C, the temperature of the third stage is 200-220°C, and the outlet temperature of the fourth stage is 180-120°C. And it can sensitively and automatically control the temperature through electric heating rods and circulating cooling water. The temperature control is realiz...

Embodiment 2

[0054]

[0055] The preparation method of the anti-interference low-temperature curing catalyst for the above-mentioned powder coating, the steps are as follows:

[0056] (1) Accurately weigh FINEDIC A-241, dicumyl peroxide, and polypropylene micropowder (average particle size 1--5 μm), put them into a pre-mixing mixer and mix for 5-8 minutes (stirring at room temperature), and discharge to obtain a mixed good material;

[0057] (2) Control the temperature of the first, second, third and fourth stages of the melting extruder (co-rotating twin-screw extruder) within the set range, the temperature of the first stage is 0-40°C, the temperature of the second stage is 150-180°C, and the temperature of the third stage is 200 ~220°C, the temperature of the four-stage outlet is 180-120°C, and the temperature of each stage during the entire extrusion process must be maintained within the range;

[0058] (3) Pour the materials mixed in step (1) into the hopper, turn on the screw of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com