Silicone rubber composite material and preparation method thereof

A technology of composite materials and silicone rubber, which is applied in the field of silicone rubber composite materials and its preparation, can solve the problems of strength reduction, cumbersome preparation process, poor thermal crack resistance, etc., and achieve the effect of low smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

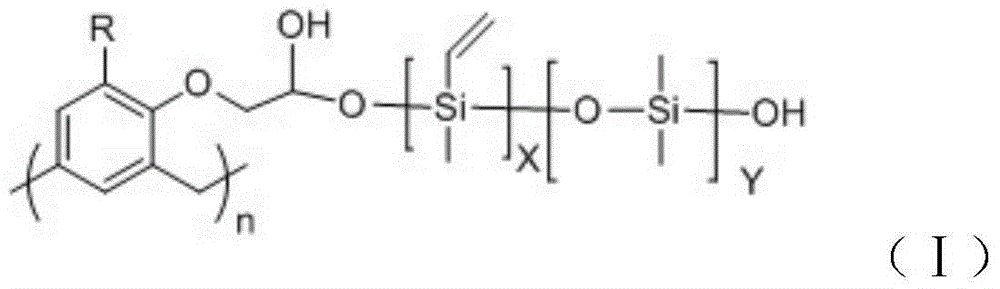

[0036] The B component of the silicone rubber matrix of the present invention contains novolac epoxy groups, utilizes the excellent bonding ability of the novolac epoxy groups and the characteristics of high carbon content, and improves the ablation resistance of the silicone resin; at the same time , the addition of phenolic resin improves the carbonization rate of the silicone rubber composite material, makes it better to form a carbonized layer, and plays the role of separating and absorbing heat. The specific preparation method includes the following:

[0037] Step 1: reacting the phenolic resin monomer with formaldehyde to obtain the first intermediate;

[0038] Step 2: reacting the first intermediate obtained in step 1 with epichlorohydrin to obtain a second intermediate;

[0039] Step 3: reacting the second intermediate obtained in Step 2 with a transition metal catalyst and organic silicone oil to obtain silicone rubber.

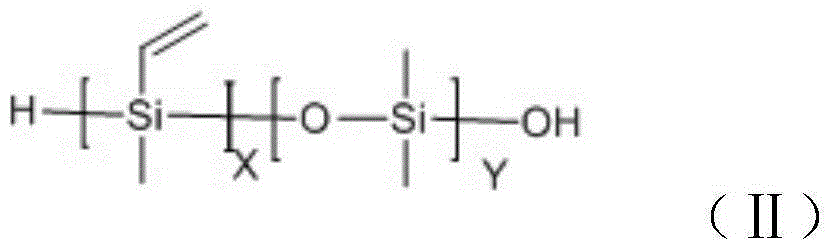

[0040] According to the present invention, fi...

Embodiment 1

[0059] Add 1 mol of m-cresol, 1 mol of formaldehyde and 80 ml of toluene into the reactor and stir evenly, heat up to 80°C and stir for 4 hours to obtain the first intermediate; cool the temperature in the reactor to room temperature and add 1 mol of epichlorohydrin and 0.01 mol tetrabutylammonium bromide, stirred at room temperature for 2h, heated to 70°C and stirred for 2h to obtain the second intermediate; the temperature in the reactor was cooled to room temperature, and 0.003mol dibutyltin dilaurate and 50% hydrogen Add potassium oxide aqueous solution into the reaction kettle, continue to add 60ml of toluene, then gradually increase the temperature to 80°C, stir for 2 hours, take a sample for detection, stop heating after the viscosity reaches 120mPas, and distill under reduced pressure to remove toluene, water and volatile small molecules generated by the reaction to obtain the reaction solution; at 50°C, slowly add 1 mol of commercially available silicone oil into the r...

Embodiment 2

[0062] Add 1 mol of m-ethylphenol, 1 mol of formaldehyde and 80 ml of toluene into the reactor and stir evenly, heat up to 70°C and stir for 5 hours to obtain the first intermediate; cool the temperature in the reactor to room temperature and add 1 mol of epichlorohydrin and 0.01 mol of tetrabutylammonium bromide, stirred at room temperature for 2h, heated to 60°C and stirred for 3h to obtain the second intermediate; the temperature in the reactor was cooled to room temperature, and 0.005mol of dibutyltin dilaurate and 50% hydrogen Add potassium oxide aqueous solution into the reaction kettle, continue to add 60ml of toluene, then gradually increase the temperature to 70°C, stir for 3 hours and then take a sample for testing, stop heating after the viscosity reaches 120mPas, and distill under reduced pressure to remove toluene, water and volatile small molecules generated by the reaction to obtain the reaction Solution; at 40°C, slowly add 1 mol of commercially available silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com