Heat-conducting, wear-resistant and insulated nylon 6 composite material and preparation method thereof

A technology of composite materials and thermally conductive fillers, applied in the field of thermally conductive and wear-resistant insulating nylon 6 composite materials and its preparation, can solve the problems of large loss of mechanical properties and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

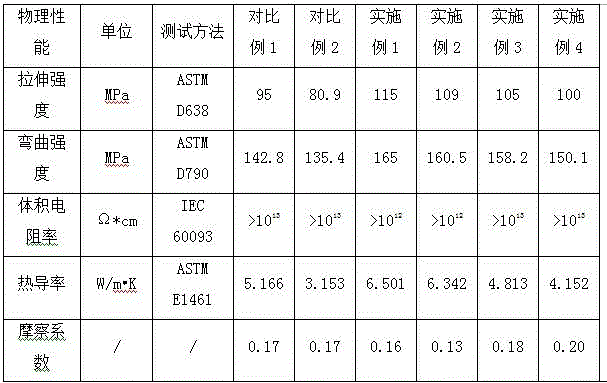

Examples

Embodiment 1

[0040] (1) Weigh raw materials according to weight ratio: PA6: 20%, 50μm magnesium oxide 30%, 3μm alumina 10%, 50μm flake graphite 10%, carbon fiber 25%, compatibilizer CMG9805 3.5%, silane coupling agent 1.5% , MB-4 0.2%, 168 / 1010 0.4%.

[0041] (2) Add the above-mentioned magnesium oxide, aluminum oxide, and flake graphite into a high-speed mixer, then add a silane coupling agent and mix evenly for later use.

[0042] (3) Add the above uniformly mixed thermally conductive filler together with PA6, processing aids and compatibilizers into a high-speed mixer, mix evenly, and then add them to the main feeding barrel of the twin-screw extruder.

[0043] (4) The above materials are extruded and granulated by a twin-screw extruder to obtain a primary granulated material. The frequency of the twin-screw host is 42Hz, the feeding frequency is 7Hz, and the temperature is 225°C.

[0044] (5) The primary granulated material is added to the main feeding barrel of the single-screw extru...

Embodiment 2

[0046] (1) Weigh raw materials according to weight ratio: PA6: 30%, 50μm alumina 20%, 3μm boron nitride 10%, 50μm flake graphite 15%, carbon fiber 20%, compatibilizer CMG9805 3.5% silane coupling agent 1.5%, MB-4 0.2%, 168 / 1010 0.4%.

[0047] (2) Add the above-mentioned alumina, boron nitride, and flake graphite into a high-speed mixer, then add a silane coupling agent and mix evenly for later use.

[0048] (3) Add the above uniformly mixed thermally conductive filler together with PA6, processing aids and compatibilizers into a high-speed mixer, mix evenly, and then add them to the main feeding barrel of the twin-screw extruder.

[0049] (4) The above materials are extruded and granulated by a twin-screw extruder to obtain a primary granulated material. The frequency of the twin-screw host is 40Hz, the feeding frequency is 9Hz, and the temperature is 235°C.

[0050] (5) The primary granulated material is added to the main feeding barrel of the single-screw extruder, extruded...

Embodiment 3

[0052] (1) Weigh raw materials according to weight ratio: PA6: 40%, 50μm magnesium oxide 20%, 5μm magnesium oxide 10%, 50μm expanded graphite 10%, carbon fiber 15%, compatibilizer CMG9805 3.5%, silane coupling agent 1.5% , MB-4 0.2%, 168 / 1010 0.4%.

[0053] (2) Add the above-mentioned magnesium oxide and expanded graphite into the high-speed mixer, then add the silane coupling agent and mix evenly for later use.

[0054] (3) Add the above uniformly mixed thermally conductive filler together with PA6, processing aids and compatibilizers into a high-speed mixer, mix evenly, and then add them to the main feeding barrel of the twin-screw extruder.

[0055] (4) The above materials are extruded and granulated by a twin-screw extruder to obtain a primary granulated material. The frequency of the twin-screw host is 40Hz, the feeding frequency is 10Hz, and the temperature is 235°C.

[0056] (5) The primary granulated material is added to the main feeding barrel of the single-screw ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com