Preparation method of super-hydrophobic particle/chitosan framework composite oil-absorption sponge

A technology of oil-absorbing sponge and chitosan, which is applied in the field of preparation of superhydrophobic oil-absorbing sponge, can solve the problems of low oil absorption rate and secondary pollution, and achieve the effects of low cost, convenient secondary recovery, and controllable experimental parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

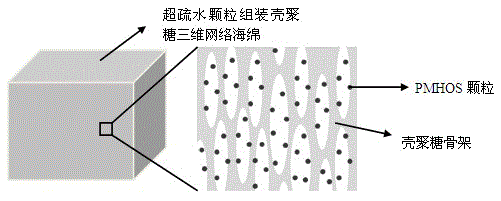

[0018] Specific implementation mode one: as figure 1 As shown, the present embodiment prepares chitosan superhydrophobic oil-absorbing sponge according to the following steps:

[0019] Step 1, prepare chitosan sponge by freeze-drying method

[0020] Chitosan powder was dissolved in acetic acid aqueous solution (2 wt %) to prepare a 0.1-10 wt % chitosan solution; the chitosan solution was transferred to an evaporating dish, the filter paper was covered on the upper part of the vessel, and sealed with scotch tape; Then it is placed in the cold steel rod on the top of the freeze dryer, cooled and completely frozen by liquid nitrogen, and the freezing temperature ranges from -5 to -60°C; the three-dimensional network chitosan is formed by freezing into ice crystals with water and drying to remove.

[0021] Step 2. Synthesis of superhydrophobic PMHOS (polymethylhydroxysiloxane)

[0022] Dissolve PMHS (2-100 g) in absolute ethanol (10-1000 mL), then add sodium hydroxide (0...

specific Embodiment approach 2

[0025] Specific embodiment two: present embodiment prepares chitosan superhydrophobic oil-absorbing sponge according to the following steps:

[0026] Step 1, prepare chitosan sponge by freeze-drying method

[0027] Chitosan powder (4g) is dissolved in the aqueous acetic acid solution (2wt%) of 200 milliliters, preparation chitosan solution (2wt%); Chitosan solution is transferred in the evaporating dish, filter paper is covered on vessel top, and with Sealed with scotch tape, then placed in the cold steel rod at the top, cooled and completely frozen by liquid nitrogen, the freezing temperature is -5°C; the three-dimensional network chitosan is formed by freezing into ice crystals with water and drying to remove them to form a three-dimensional network Chitosan backbone.

[0028] Step 2. Synthesis of superhydrophobic PMHOS (polymethylhydroxysiloxane)

[0029] PMHS (4.7 g, 78 mmol MeHSiO) was dissolved in absolute ethanol (70 mL), and then a solution of sodium hydroxid...

specific Embodiment approach 3

[0033] Specific embodiment three: present embodiment prepares chitosan superhydrophobic oil-absorbing sponge according to the following steps:

[0034] Step 1, prepare chitosan sponge by freeze-drying method

[0035] Chitosan powder (4 g) was dissolved in 200 ml of acetic acid aqueous solution (2 wt %) to prepare chitosan solution (2 wt %). Transfer the chitosan solution to an evaporating dish, cover the upper part of the vessel with filter paper, and seal it with scotch tape, then place it in a cold steel rod at the top, cool and completely freeze it with liquid nitrogen, and the freezing temperature is -20 °C. The three-dimensional network chitosan is formed by freezing water into ice crystals and drying to remove the three-dimensional network chitosan skeleton.

[0036] Step 2. Synthesis of superhydrophobic PMHOS (polymethylhydroxysiloxane)

[0037] PMHS (4.7 g, 78 mmol MeHSiO) was dissolved in absolute ethanol (70 mL), then sodium hydroxide (0.008 g, 0.2 mmol in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com