A kind of silicone rubber and preparation method thereof

A technology of silicone rubber and silicone oil, applied in the field of silicone rubber, can solve the problems of poor ablation resistance and adhesion of silicone rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

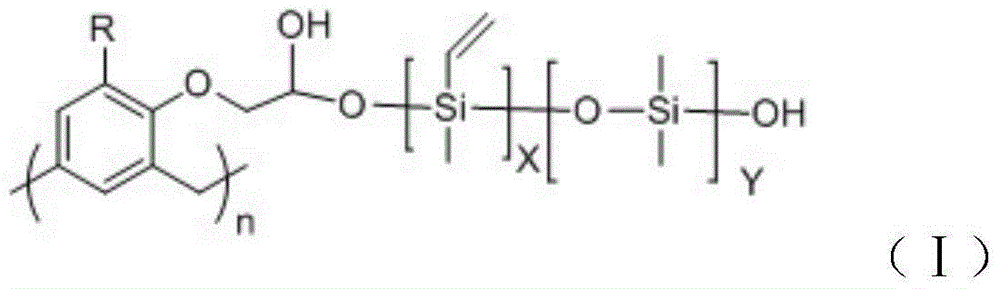

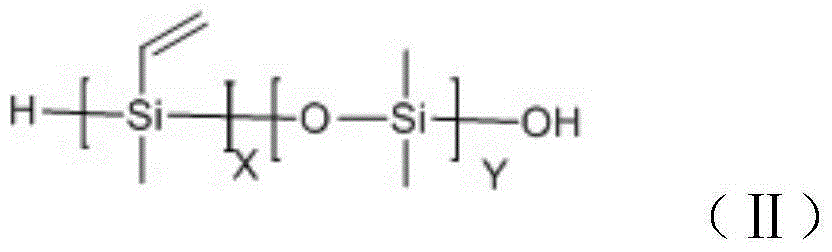

[0030] The present invention also provides a kind of preparation method of silicone rubber, comprises as follows:

[0031] Step 1: reacting the phenolic resin monomer with formaldehyde to obtain the first intermediate;

[0032] Step 2: reacting the first intermediate obtained in step 1 with epichlorohydrin to obtain a second intermediate;

[0033] Step 3: reacting the second intermediate obtained in Step 2 with a transition metal catalyst and organic silicone oil to obtain silicone rubber.

[0034] According to the present invention, first put the phenolic resin monomer and formaldehyde into the reaction container, add an organic solvent, the organic solvent is preferably toluene, after stirring evenly, heat up the reaction to obtain the first intermediate, the reaction temperature is preferably 70-90°C, more preferably 80°C, the reaction time is preferably 3-5h, more preferably 4h; the molar ratio of the phenolic resin to formaldehyde is preferably 1:1. The phenolic resin m...

Embodiment 1

[0047]

[0048] Add 1 mol of m-cresol, 1 mol of formaldehyde and 80 ml of toluene into the reactor, stir evenly, raise the temperature to 80°C and stir for 4 hours to obtain the first intermediate; cool the temperature inside the reactor to room temperature, then add 1 mol of epichlorohydrin and 0.01 mol tetrabutylammonium bromide, stirred at room temperature for 2h, heated to 70°C and stirred for 2h to obtain the second intermediate; the temperature in the reactor was cooled to room temperature, and 0.003mol dibutyltin dilaurate and 50% hydrogen Add potassium oxide aqueous solution into the reaction kettle, continue to add 60ml of toluene, then gradually increase the temperature to 80°C, stir for 2 hours, take a sample for detection, stop heating after the viscosity reaches 120mPas, and distill under reduced pressure to remove toluene, water and volatile small molecules generated by the reaction to obtain the reaction solution; at 50°C, slowly add 1 mol of commercially avai...

Embodiment 2

[0055]

[0056]

[0057] Add 1 mol of m-ethylphenol, 1 mol of formaldehyde and 80 ml of toluene into the reactor and stir evenly, heat up to 70°C and stir for 5 hours to obtain the first intermediate; cool the temperature in the reactor to room temperature and add 1 mol of epichlorohydrin and 0.01 Tetrabutylammonium bromide, stirred at room temperature for 2 hours, heated to 60°C and stirred for 3 hours to obtain the second intermediate; the temperature in the reactor was cooled to room temperature, and 0.005mol dibutyltin dilaurate and 50% hydroxide Add potassium aqueous solution into the reaction kettle, continue to add 60ml of toluene, then gradually increase the temperature to 70°C, stir for 3 hours, take a sample for testing, stop heating after the viscosity reaches 120mPas, and distill under reduced pressure to remove toluene, water and volatile small molecules generated by the reaction to obtain a reaction solution ; At 40°C, slowly add 1 mol of commercially availa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com