Desalination and purification method of pentasodium diethylenetriamine pentaacetic acid (DTPA)

A purification method, pentasodium salt technology, which is applied in the field of desalination and purification of DTPA pentasodium salt, can solve the problems of inconvenient production management, restrictions, high salt content, etc., achieve good social and economic benefits, reduce environmental protection investment, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

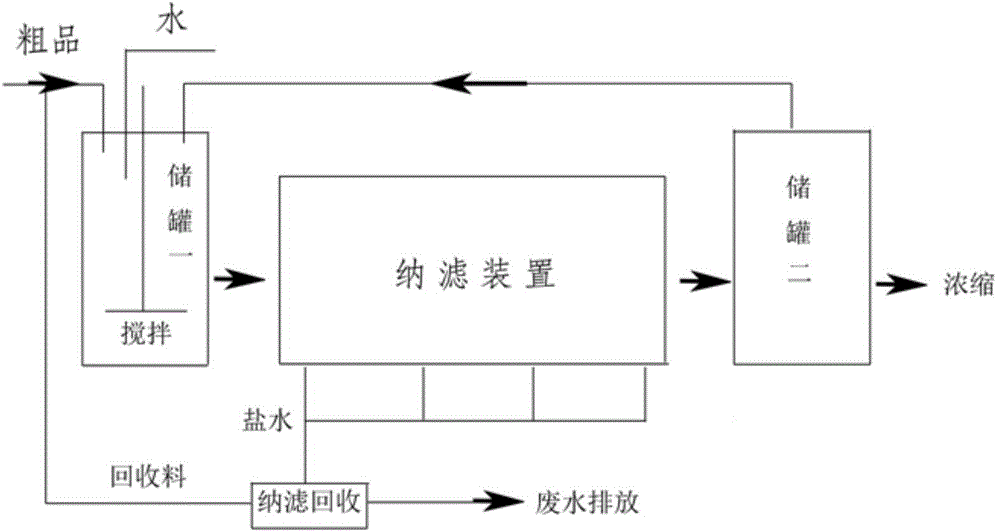

Image

Examples

Embodiment 1

[0058] DTPA pentasodium salt crude product solution preparation:

[0059] Dissolve 240 kg of chloroacetic acid in 80 kg of deionized water, slowly add 52 kg of diethylenetriamine, turn on the cooling device, and put ice water into the jacket to control the temperature of the reaction system at -10~-5°C; then slowly divide into 2 batches Add 630 kg of 32-33% sodium hydroxide solution. When the first 315 kg of sodium hydroxide solution is slowly added, the jacket is passed into ice water to control the reaction temperature at -10~-5°C; when the last 315 kg of sodium hydroxide solution is slowly added, Water is passed into the jacket to control the temperature of the reaction system to be 55-60°C, and the sodium hydroxide solution is added to keep warm for 3 hours; the pH value of the solution is adjusted to 11.5, and the solution is lowered to room temperature, and the material is filtered out. At this time, the content of DTPA pentasodium salt It was 24.8%, and the yield was 99...

Embodiment 2

[0066] DTPA pentasodium salt crude product solution preparation:

[0067] Dissolve 240 kg of chloroacetic acid in 80 kg of deionized water, slowly add 52 kg of diethylenetriamine, turn on the cooling device, put ice water into the jacket to control the temperature of the reaction system at -5 ~ 0 °C; then slowly add in 2 batches 630 kg of 32-33% sodium hydroxide solution. When the first 315 kg of sodium hydroxide solution is slowly added, the jacket is fed with ice water to control the reaction temperature at -5~0°C; when the last 315 kg of sodium hydroxide solution is slowly added, the jacket Feed water to control the temperature of the reaction system to be 45-50°C, and keep warm for 4 hours after adding the sodium hydroxide solution; adjust the pH value of the solution to 11.5, drop to room temperature, and filter the material. At this time, the content of DTPA pentasodium salt is 24.5 %, the yield is 98%.

[0068] Purification of crude product of DTPA pentasodium salt:

...

Embodiment 3

[0074] DTPA pentasodium salt crude product solution preparation:

[0075] Dissolve 240 kg of chloroacetic acid in 80 kg of deionized water, slowly add 52 kg of diethylenetriamine, turn on the cooling device, put ice water into the jacket to control the temperature of the reaction system at 0-5°C; then slowly add 630 Kg of 32-33% sodium hydroxide solution. When the first 315 kg of sodium hydroxide solution is slowly added, the jacket is passed into ice water to control the reaction temperature at 0-5°C; when the last 315 kg of sodium hydroxide solution is slowly added, the jacket is passed into water The temperature of the control reaction system is 50~55 ℃, and the sodium hydroxide solution is added and incubated for 5 hours after the end; the pH value of the solution is adjusted to 11.5, down to room temperature, and filtered to discharge the material. At this time, the content of DTPA pentasodium salt is 24%. The yield was 96%.

[0076] Purification of crude product of DTPA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com