Chain stopping device and windlass

A windlass and chain stop technology, which is applied in the direction of anchor arrangement, transportation and packaging, anchor treatment/binding, etc. It can solve the problems of large force between the chain stopper and the anchor chain ring, occupying space, damage to the anchor chain, etc., and achieves saving effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

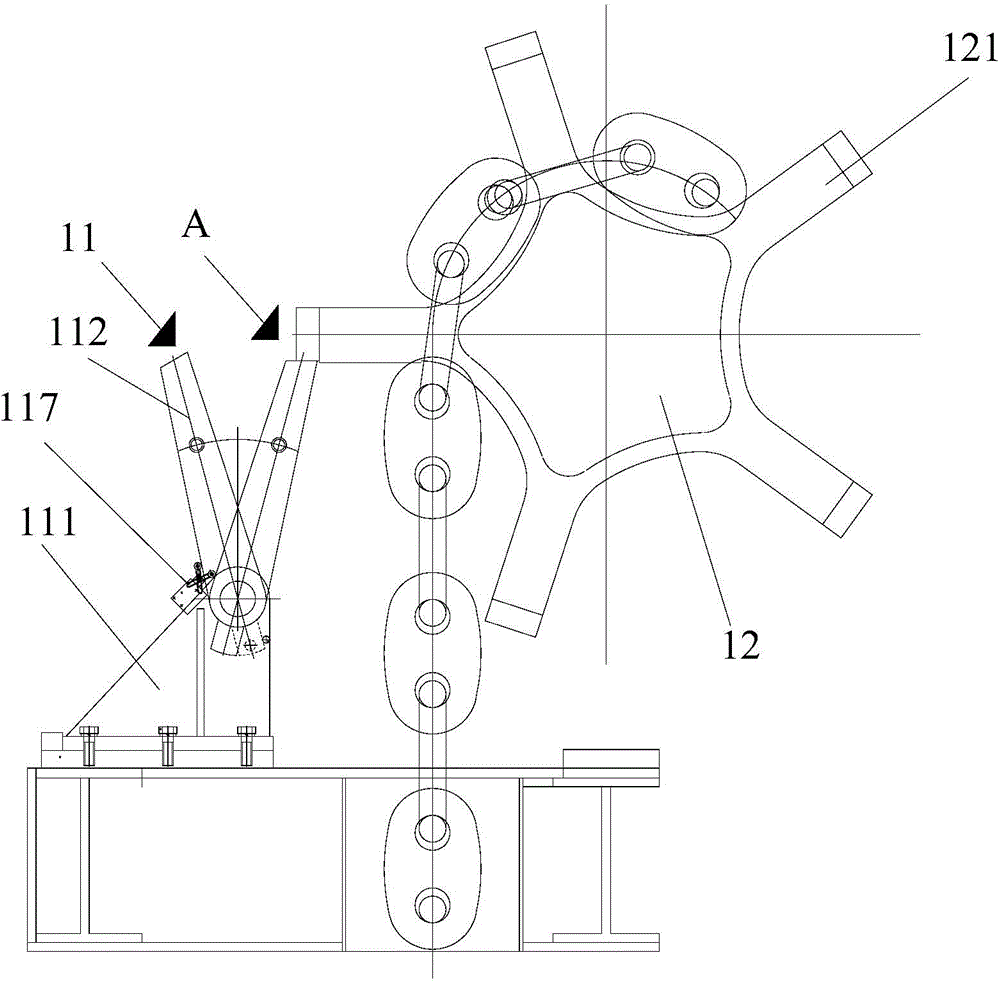

[0032] The embodiment of the present invention provides a chain stop device, see figure 1 , the device comprises: a chain stopper 11 and a chain wheel 12 rotatably mounted on the windlass frame.

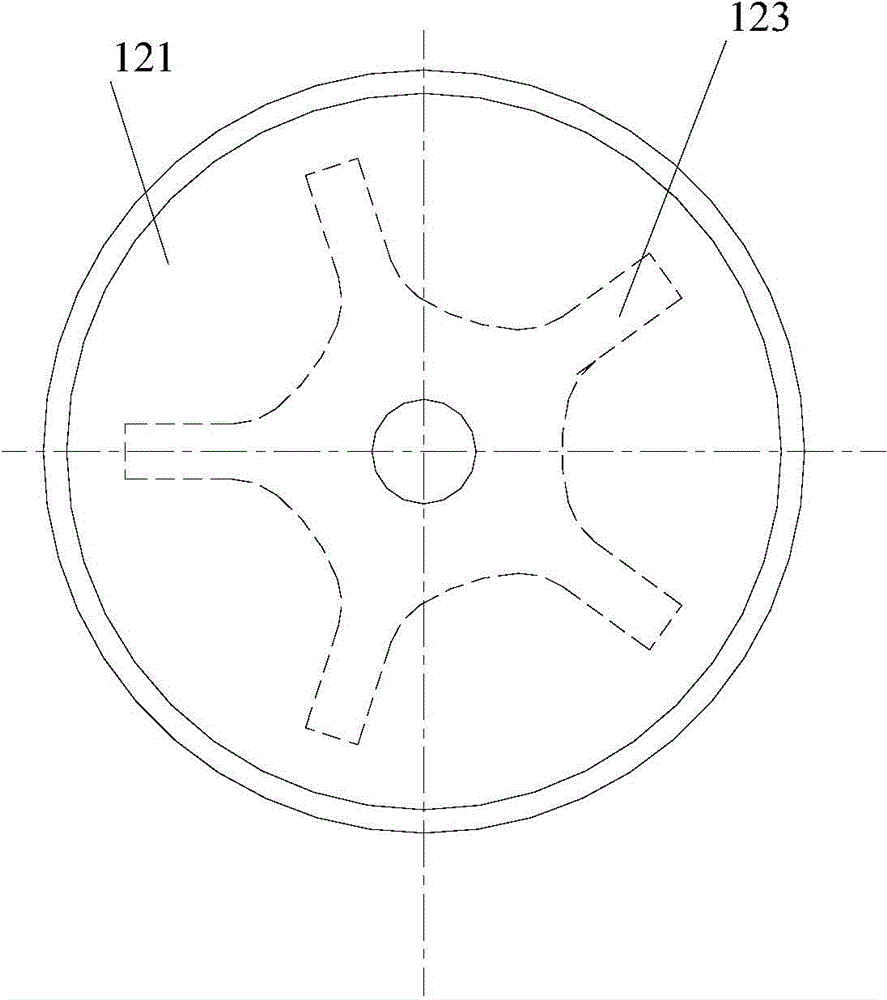

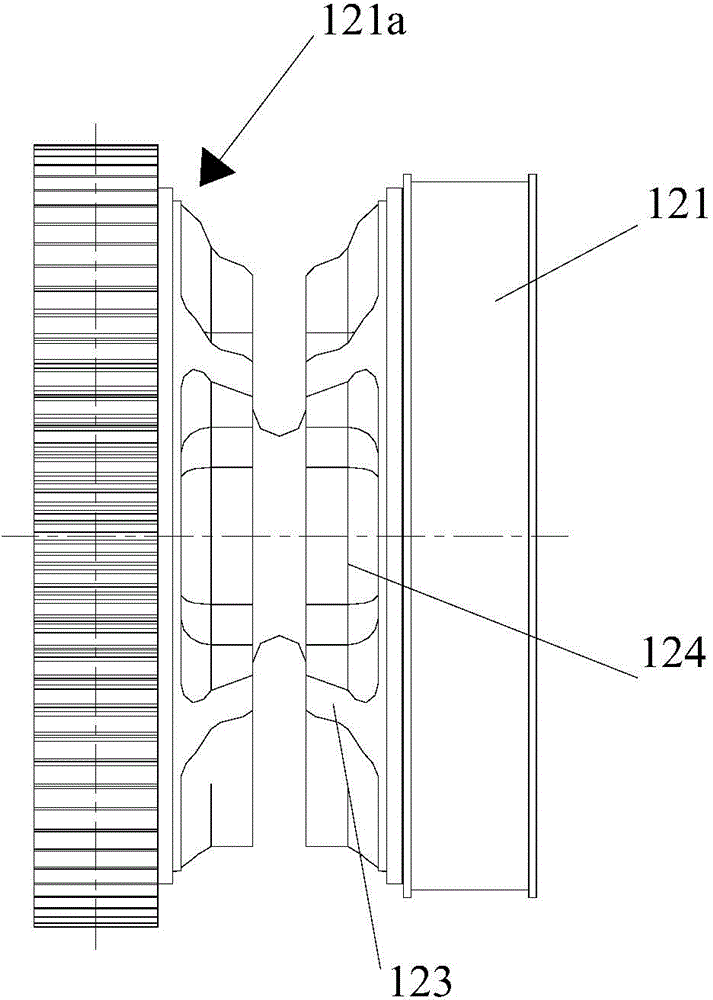

[0033] Such as Figure 2a and Figure 2b As shown, the chain wheel 12 includes two chain wheel plates 121 arranged in parallel and a connecting shaft 122 connecting the two chain wheel plates. The connecting shaft 122 is provided with a groove 124 matching the anchor chain, and when the anchor chain is wound on the anchor wheel, the anchor chain ring rests in the groove 124 . In order to facilitate understanding of the embodiments of the present invention, figure 1 The structure of the anchor chain wheel plate and the connecting shaft of the anchor chain wheel is omitted in the figure.

[0034] In this embodiment, the two anchor chain wheel plates 121 are respectively provided with a plurality of claws 123, and the claws 123 on each anchor chain wheel plate 121 are arranged at in...

Embodiment 2

[0050] The embodiment of the present invention also provides a windlass, which includes a windlass frame, a driving device, a roller, a chain stop device, an anchor chain and an anchor. The drum is rotatably mounted on the windlass frame, the chain stop device is installed on the windlass frame, the anchor chain is wound on the drum and passes around the chain wheel, and the anchor is connected to one end of the anchor chain. The chain stopping device is the chain stopping device provided in the first embodiment.

[0051] In this embodiment, the chain stop device can be installed on the windlass frame by using bolts, or the chain stop device can be directly welded on the windlass frame.

[0052] Optionally, the windlass also includes a braking device for braking the drum.

[0053] When anchoring and anchoring are needed, the stop arm is pushed back to the anchor chain wheel, so that the chain stopper is in the open state of the chain stopper, and the windlass can normally rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com