Milling mechanism for milling machines special for tube plate partitions

A special milling machine and clapboard technology, which is applied in the field of milling machines, can solve the problems of affecting the economic benefits of enterprises, long outsourcing processing time, and high processing costs, and achieve the effects of saving round-trip transportation costs, improving corporate reputation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

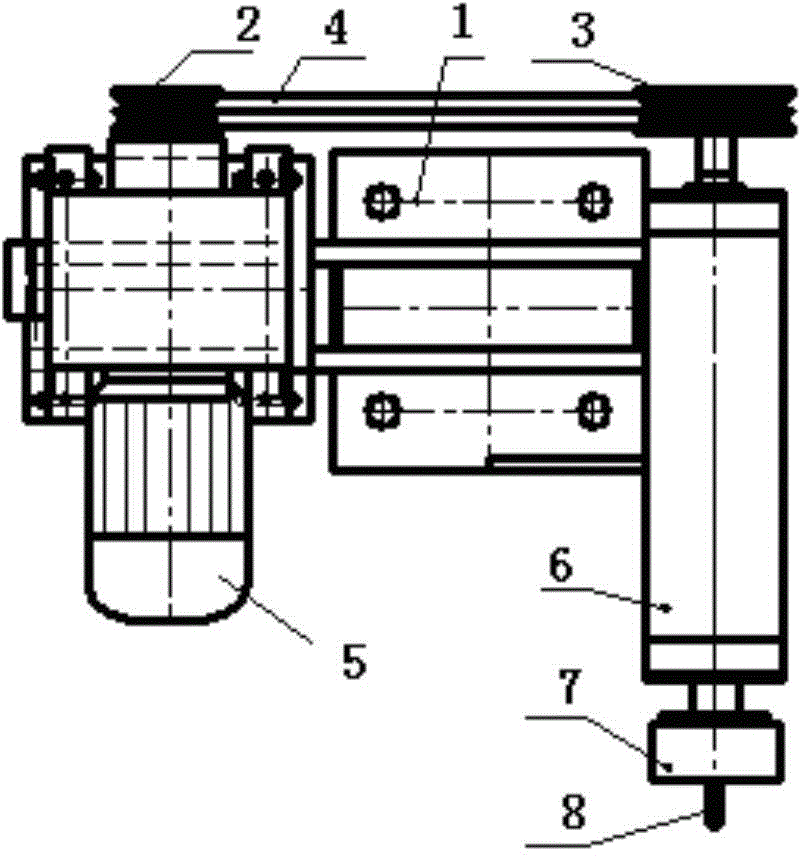

[0014] Referring to the accompanying drawings, the milling mechanism of the special milling machine for tube plate partitions includes a fixed frame 1, a small pulley 2, a large pulley 3, a V-belt 4, and a speed regulating motor 5. The large pulley 3 is fixedly connected to a main shaft 6, and the lower end of the main shaft 6 is installed There are three-jaw chuck 7, milling cutter 8, and the fixed frame is fixedly connected with the middle carriage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com