Continuous-casting crystallizer vibration simulation test unit and non-sine vibration control method thereof

A technology of continuous casting mold and simulation test, applied in the field of continuous casting mold simulation application of iron and steel metallurgy, can solve the problems of unfavorable technical level, high operation and maintenance, expensive investment, etc., and achieves a simple and clear speed curve, strong adaptability, Easy-to-get effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

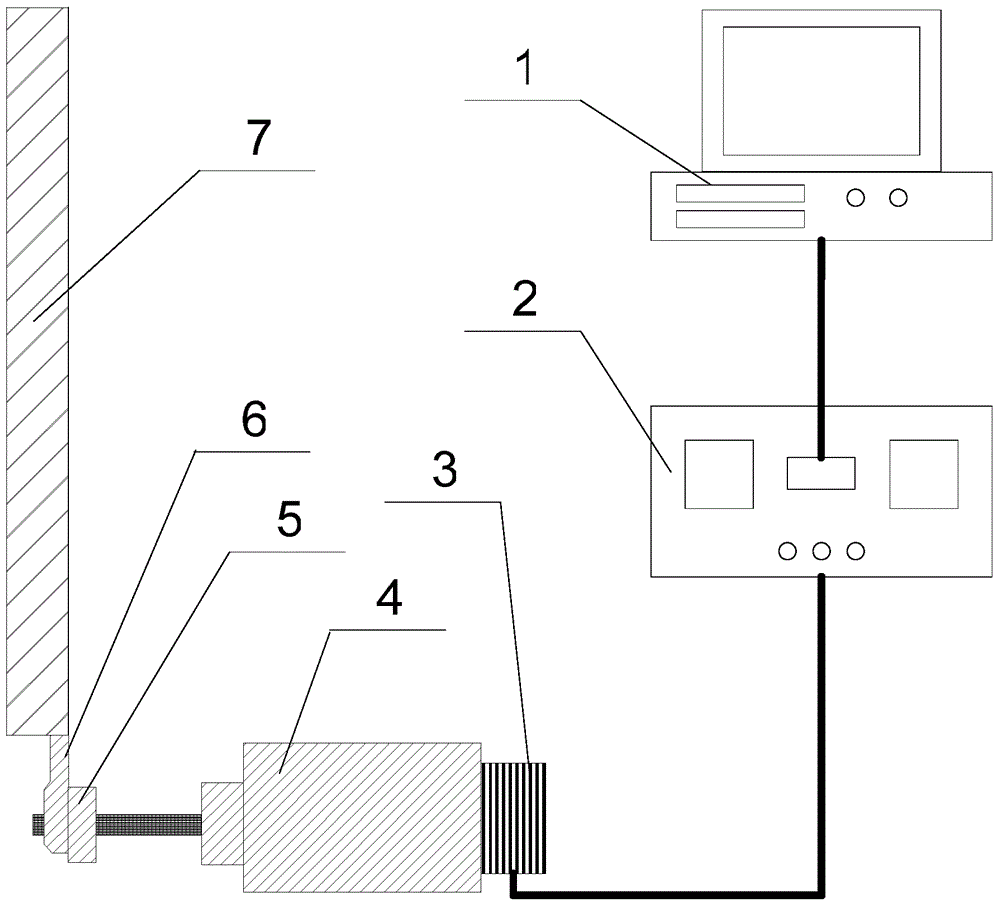

[0027] like figure 1 As shown, a continuous casting crystallizer vibration simulation test device includes a main control computer 1, a controller 2, a motor driver 3, a stepping motor 4, an eccentric wheel 5, a connecting rod 6 and a device for simulating a continuous casting mold copper plate Vibration plate 7;

[0028] The main control computer 1 is connected to the input end of the controller 2, the output end of the controller 2 is connected to the input end of the motor driver 3, the output end of the motor driver 3 is connected to the control input end of the stepping motor 4, and the output shaft of the stepping motor 4 is connected to An eccentric wheel 5, one side of the eccentric wheel 5 is connected to one end of the connecting rod 6, and the vibrating plate 7 is vertically connected to the other end of the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com