Dispersive droplet emulsion and preparation method thereof

A technology for dispersing liquid droplets and emulsions, applied in the field of chemical engineering, can solve the problems of wide distribution of dispersed liquid droplet diameters and poor controllability of dispersed liquid droplet diameters, and achieve the effect of avoiding large equipment volume, economical and practical operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] According to a typical embodiment of the present invention, a method for preparing a dispersed droplet emulsion is provided, comprising the following steps: mixing a hydrophobic organic solvent and a hydrophilic organic solvent according to a mass ratio of 1:20 to 1:2000 to obtain a dispersing solvent; and mixing the dispersing solvent and the aqueous solution of the inorganic salt to form a dispersed uniform droplet emulsion; wherein the dispersing solvent and the aqueous solution of the inorganic salt are mixed in a static mixer.

[0022] In the present invention, a hydrophilic organic solvent is mixed with a hydrophobic organic solvent to obtain a dispersive solvent, and the dispersive solvent is sent to a static mixer to mix with an aqueous solution of inorganic salt, so that the dispersed solvent with controllable particle size and wide diameter distribution can be rapidly prepared. Uniform droplet emulsion. The preparation method of the present invention is simple...

Embodiment 1

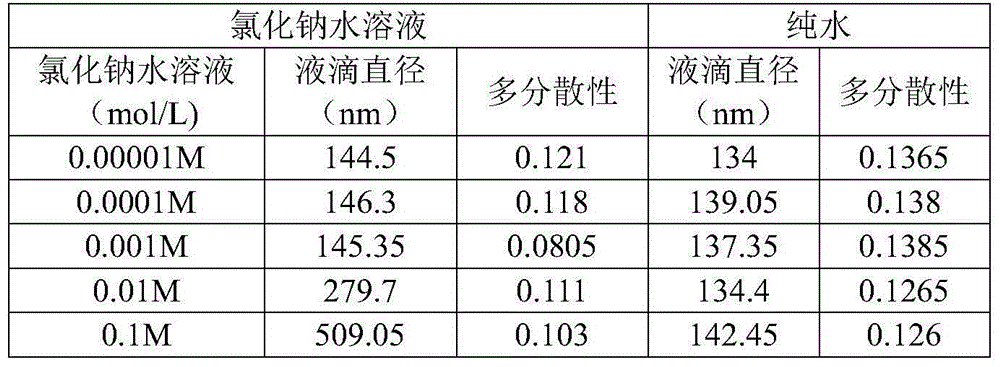

[0036] Mix hexadecane and methanol according to the mass percentage of 1:2000 to obtain a dispersing solvent, wherein the ratio of the moles of hexadecane to the volume of methanol is 1.0×10 -4 mol / L. The dispersing solvent was ultrasonically degassed for 5 minutes to form a homogeneous dispersing solvent. The homogeneous dispersibility solvent is placed in the first syringe pump 11, and the sodium chloride aqueous solution is placed in the second syringe pump 12. Driven by the first syringe pump 11 and the second syringe pump 12, the homogeneous dispersibility The solvent and the aqueous sodium chloride solution are mixed in the SV type static mixer 2 to form a dispersed droplet emulsion, and the emulsion of the dispersed liquid continues to flow forward into the collecting vessel 3, and the pH value of the dispersed droplet emulsion is adjusted to 3.0 with hydrochloric acid.

[0037] According to the above method, the prepared dispersing solvent is divided into 10 parts, an...

Embodiment 2~5

[0043] Mix n-dodecane and acetone according to the ratio in Table 2 to obtain a dispersing solvent. The dispersing solvent was ultrasonically degassed for 5 minutes to form a homogeneous dispersing solvent. Put the homogeneous dispersion solution into the first syringe pump 11, put the 0.001mol / L sodium chloride solution into the second syringe pump 12, under the drive of the first syringe pump 11 and the second syringe pump 12, Mix the homogeneous dispersing solvent and potassium chloride aqueous solution in a static mixer to form a dispersed droplet emulsion, and the dispersed droplet emulsion continues to flow forward in the collection vessel 3, and adjust the pH value of the dispersed droplet emulsion with sodium hydroxide to 6.0. The diameter of the droplet was measured by the dynamic light scattering method and the particle size distribution of the droplet was counted. The samples were measured three times, and the average value was taken. The specific data are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com