Dental implant surgery guide plate for complete tooth loss and manufacturing method thereof

A dental implant and guide plate technology, which is applied in dental prosthetics, dentistry, dental implants, etc., can solve the problems of mucosal positioning drift, inaccurate positioning, and large trauma, and achieve the effects of pain relief, accurate positioning, and small trauma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

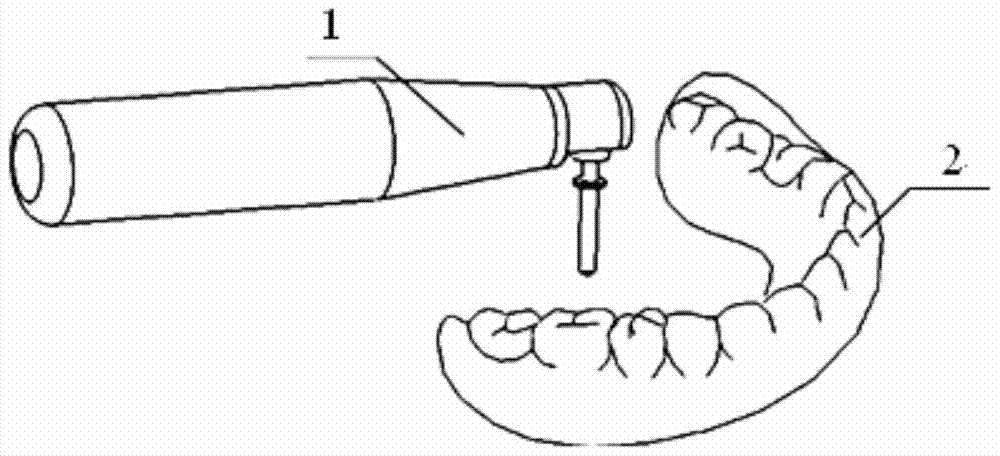

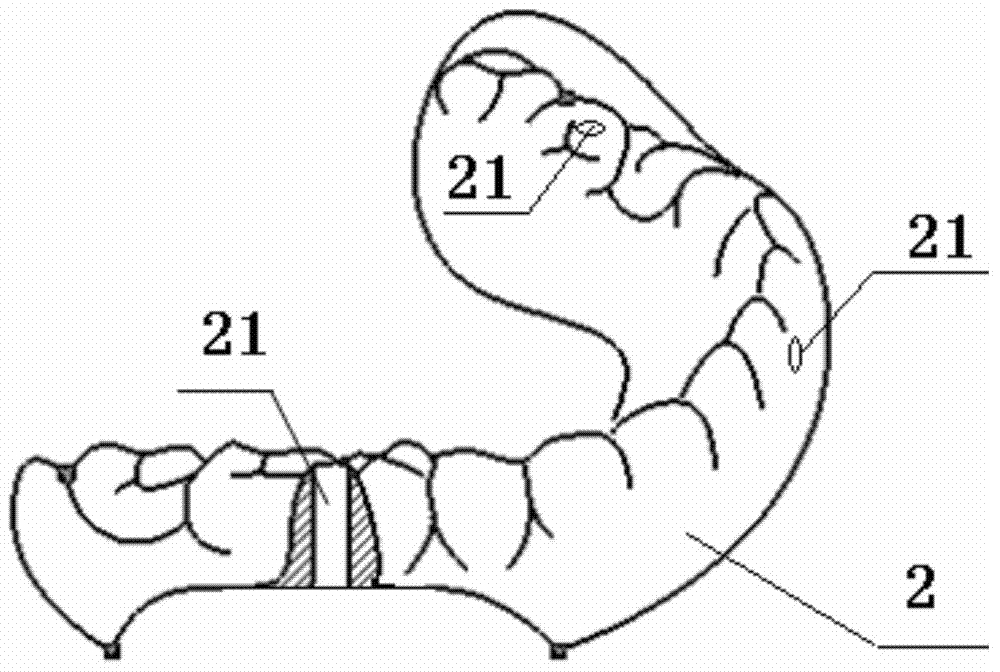

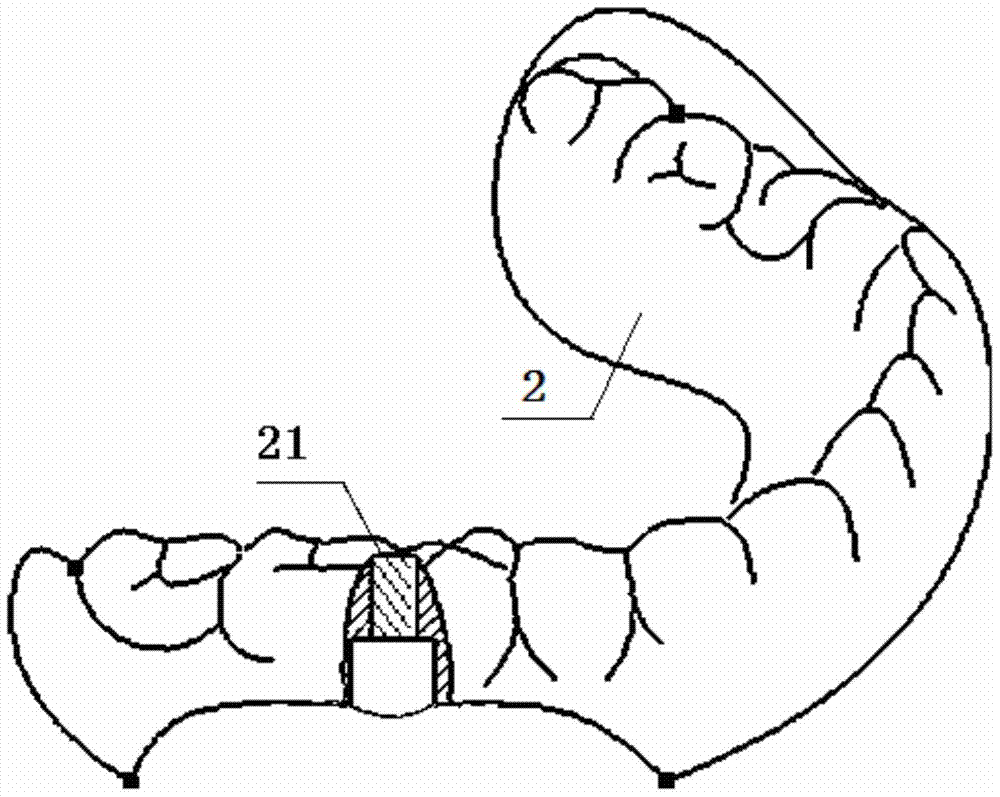

[0031] Such as Image 6 , 7 As shown, the dental implant surgery guide plate for full dentition is in contact with the alveolar bone or mucous membrane to locate the base body 5 at the surgical site. The base body 5 is provided with at least one guide hole 51 for drilling, and each guide The hole 51 corresponds to the corresponding implant socket on the alveolar bone; the base body 5 is provided with a positioning hole 52, and the positioning hole 52 cooperates with the positioning nail 4 arranged in the patient's oral cavity; the guide plate platform 53 is used as a positioning surface for controlling the drilling of the drill bit depth. The positioning pin 4 is fixed in the patient's oral cavity as a positioning reference. When the positioning pin 4 is inserted into the positioning hole 52 of the base 5, the position of the base 5 can be locked to prevent the base 5 from drifting, so that patients with complete dentition can also use it The guide plate is used for dental i...

Embodiment 2

[0035] The method for making the dental implant guide plate with complete tooth loss includes the following steps:

[0036] 1) Preliminarily determine the position of the positioning pin 4 on the patient's gum bed, and fix the positioning pin 4 on the corresponding position of the gum 3; the method of fixing the positioning pin 4 on the gum 3 is to implant the positioning pin 4 into the patient's alveolar bone ; The positioning nail 4 is fixed on the patient's gums 3 as Figure 5 shown;

[0037] 2) Take a CT scan of the patient's oral cavity, and determine the implantation plan based on the CT data. The content of the implantation plan includes the number of implants, the type of implants, and the distribution of implants; The number of holes to be prepared on the patient's alveolar bone, the distribution position of the implants corresponds to the distribution of the prepared holes on the alveolar bone, and the type of implant corresponds to the shape and depth of the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com