Method for processing onion juice by ultrasonic-assisted biological enzymolysis technology

An ultrasonic and bio-enzyme technology is applied in the field of onion juice processing by ultrasonic-assisted bio-enzymolysis technology, which can solve the problems of insufficient utilization of filter residue, low onion juice yield, and high intensity of wastewater treatment, so as to improve comprehensive utilization value and process design. Scientific and reasonable, less environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Soak the onion in water for 30 minutes, then wash off the old skin, soil and other impurities on the outside of the yellow onion with a fruit brushing machine, and use a rotary hammer crusher to crush the onion into slurry particles below 2.5mm. Then the slurry particles are processed by a belt filter press (filter cloth pore size φ0.5mm) and press-filtered to obtain filtered juice and filter residue. After the filtered juice is separated by a 3000rpm high-speed disc machine, the onion juice and filter residue are obtained. After mixing the above-mentioned filter residue after press filtration and centrifugation, add 1 times its weight of water, place it in an ultrasonic treatment device, add pectinase and cellulase, start ultrasonic, and perform ultrasonic enzymatic hydrolysis. The ratio of pectinase to cellulase is 1:1, the added amount is 0.05% of the weight of the filter residue, the pH value of the enzymatic hydrolysis is 4, the enzymatic hydrolysis temperature is ...

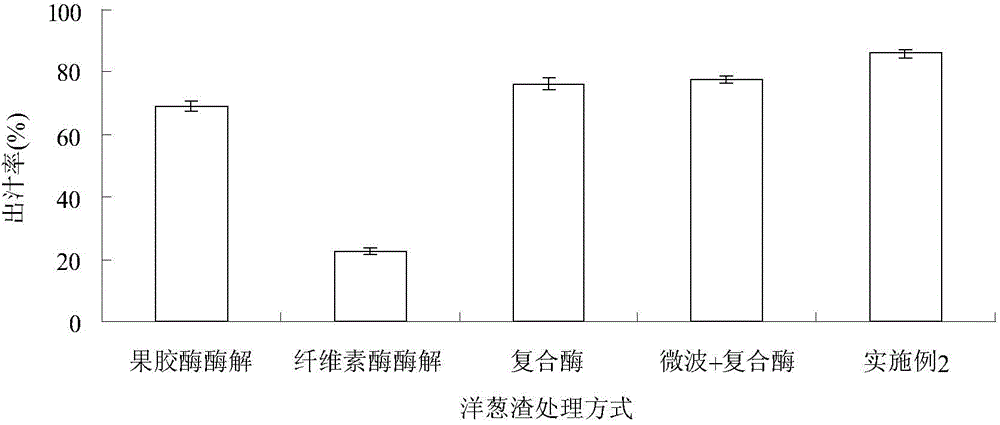

Embodiment 2

[0043] Soak the onion in water for 60 minutes, then wash off the old skin, soil and other impurities on the outside of the yellow onion with a fruit brushing machine, and use a rotary hammer crusher to crush the onion into slurry particles below 2.5mm. Then the slurry particles are processed by a belt filter press (filter cloth aperture φ0.8mm) to obtain filtered juice and filter residue. After the filtered juice is separated by a 3000rpm high-speed disc machine, the onion juice and filter residue are obtained. After mixing the above-mentioned filter residue after press filtration and centrifugation, add water 3 times its weight, place it in an ultrasonic treatment device, add pectinase and cellulase, start ultrasonic, and perform ultrasonic enzymolysis. The ratio of pectinase to cellulase is 3:1, the added amount is 0.1% of the weight of the filter residue, the pH value of the enzymatic hydrolysis is 5, the enzymatic hydrolysis temperature is 50°C, and the enzymatic hydrolysi...

Embodiment 3

[0045] Soak the onion in water for 50 minutes, then wash off the old skin, soil and other impurities on the outside of the yellow onion with a fruit brushing machine, and use a rotary hammer crusher to crush the onion into slurry particles below 2.5mm. Then the slurry particles are processed by a belt filter press (filter cloth pore size φ1.0mm) to obtain filtered juice and filter residue. After the filtered juice is separated by a 3000rpm high-speed disc machine, the onion juice and filter residue are obtained. After mixing the above-mentioned filter residue after press filtration and centrifugation, add 1 times its weight of water, place it in an ultrasonic treatment device, add pectinase and cellulase, start ultrasonic, and perform ultrasonic enzymatic hydrolysis. The ratio of pectinase to cellulase is 2:1, the added amount is 0.08% of the weight of the filter residue, the pH value of the enzymatic hydrolysis is 4.5, the enzymatic hydrolysis temperature is 45°C, and the enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com