Organic electroluminescent device and preparation method thereof

An electroluminescent device and electroluminescent technology, which are applied in the fields of electro-solid devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low device life, large current driving light-emitting devices, low luminous efficiency, etc., and improve the injection rate. efficiency, reducing the starting voltage, and improving the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

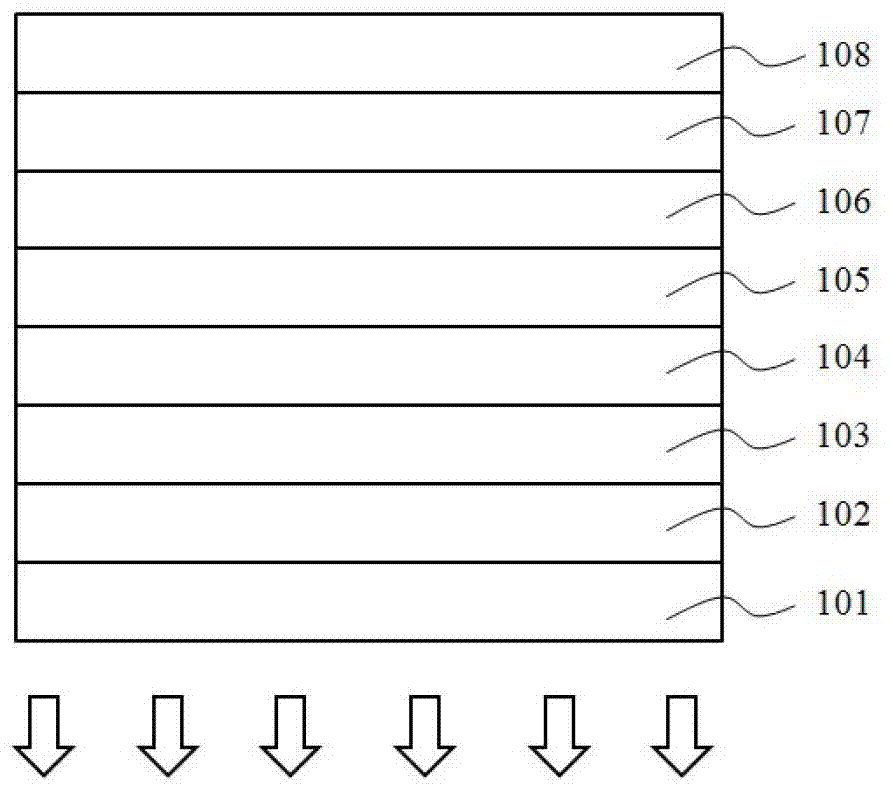

[0044] The organic electroluminescent device of this embodiment has a structure of: glass / ITO / ReCl 4 :m-MTDATA / TAPC / NPB:Ir(MDQ) 2 (acac) / BAlq / Li 2 CO 3 :Alq 3 / Ag

[0045] The fabrication method of the organic electroluminescent device is as follows:

[0046] 1. Use detergent, deionized water, isopropanol, and acetone to ultrasonically clean the glass substrate for 20 minutes, and then dry it with nitrogen;

[0047] 2. After the glass is cleaned, it is placed in a vacuum sputtering system, and an indium-doped tin oxide (ITO) film with a thickness of 100 nm is sputtered on its surface as an anode layer; then treated with plasma;

[0048] 3. In the vacuum thermal evaporation system, the hole transport layer (the material is ReCl 4 Doped into m-MTDATA, expressed as ReCl 4 :m-MTDATA, ReCl 4 The doping mass ratio is 5%, the thickness is 30nm), the electron blocking layer (the material is TAPC, the thickness is 10nm), the light-emitting layer (the material is Ir(MDQ) 2 (aca...

Embodiment 2

[0050] The organic electroluminescence device of the present embodiment, its structure is: glass / ITO) / ReF 4 :MeO-TPD / TAPC / TCTA:Ir(ppy) 3 / TPBi / LiN 3 :TPBi / Al.

[0051] The fabrication method of the organic electroluminescent device is as follows:

[0052] 1. Use detergent, deionized water, isopropanol, and acetone to ultrasonically clean the glass substrate for 20 minutes, and then dry it with nitrogen;

[0053] 2. After the glass is cleaned, it is placed in a vacuum sputtering system, and an indium-doped tin oxide (ITO) film with a thickness of 100 nm is sputtered on its surface as an anode layer; then treated with plasma;

[0054] 3. In the vacuum thermal evaporation system, the hole transport layer (the material is ReF 4 Doped into: MeO-TPD, expressed as ReF 4 : MeO-TPD, ReF 4 The doping mass ratio is 10%, the thickness is 50nm), the electron blocking layer (the material is TAPC, the thickness is 5nm), the light-emitting layer (the material is Ir(ppy) 3 Doped as a gu...

Embodiment 3

[0056] The organic electroluminescence device of present embodiment, its structure is: glass / ITO / ReCl 5 :NPB / TAPC / TCTA:Ir(ppy) 3 / BAlq / LiF:BAlq / Al-Mg.

[0057] The fabrication method of the organic electroluminescent device is as follows:

[0058] 1. Use detergent, deionized water, isopropanol, and acetone to ultrasonically clean the glass and wash the substrate for 20 minutes, and then dry it with nitrogen;

[0059] 2. After the glass is cleaned, it is placed in a vacuum sputtering system, and an indium-doped tin oxide (ITO) film with a thickness of 100 nm is sputtered on its surface as an anode layer; then treated with plasma;

[0060] 3. In the vacuum thermal evaporation system, the hole transport layer (the material is ReCl 5 Doped into NPB, expressed as ReCl 5 : NPB, ReCl 5The doping mass ratio is 15%, the thickness is 100nm), the electron blocking layer (the material is TAPC, the thickness is 10nm), the light-emitting layer (the material is Ir(ppy) 3 Doped as a gue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com