Functionalized grapheme/superparamagnetic ferroferric oxide nano particle composite material and preparation method thereof

A technology of ferroferric oxide and superparamagnetism, which is applied to the magnetism of organic materials/organic magnetic materials, iron oxide/iron hydroxide, nanotechnology, etc., can solve the problems of difficult modification of functional groups and weak hydrophilicity, and achieve Strong external magnetic field response, good durability, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

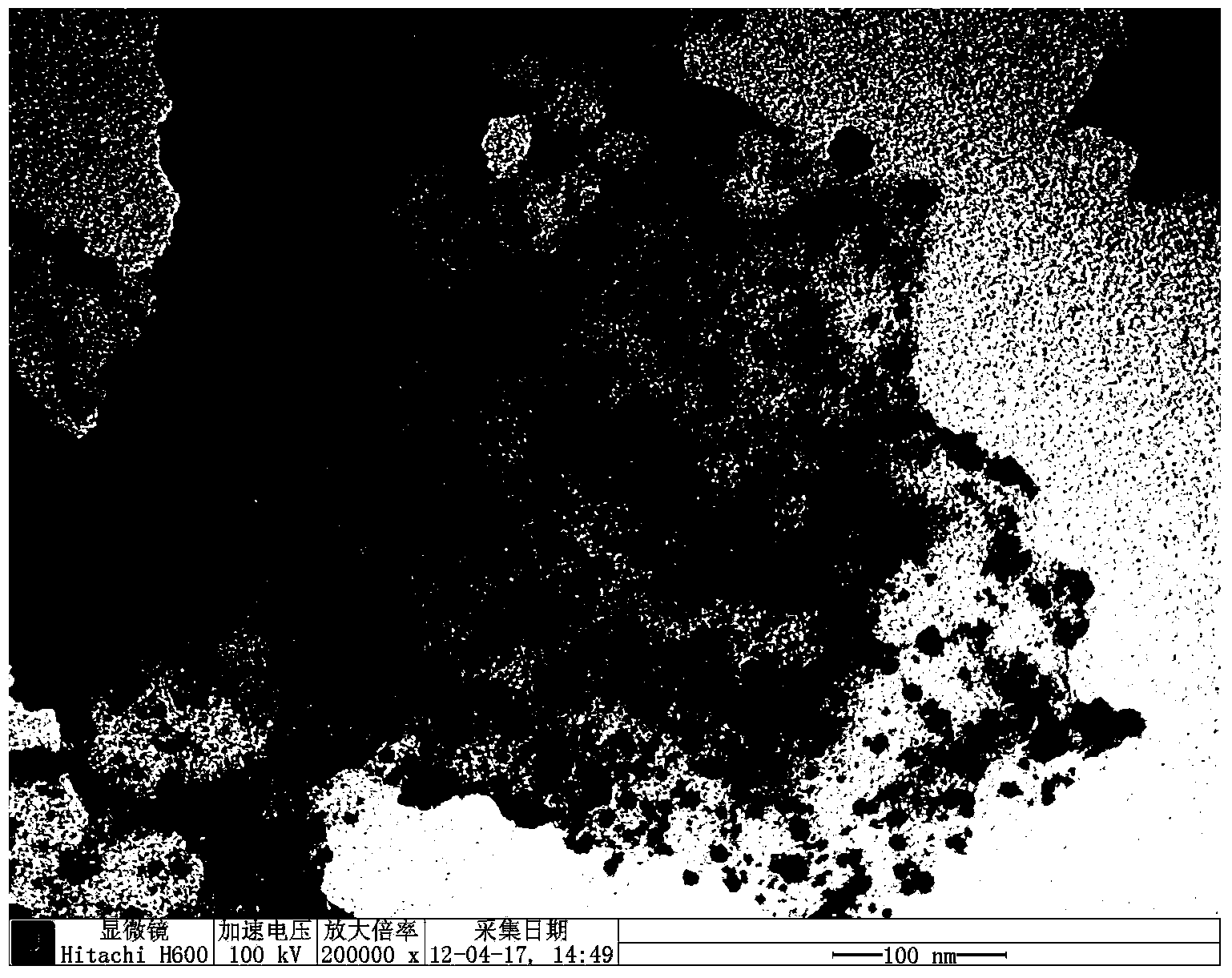

Image

Examples

preparation example Construction

[0029] In the preparation method of the above-mentioned functionalized graphene, the aqueous solution of the polymer can be obtained commercially, wherein, the average molecular weight of polyacrylamine is 15,000, and the average molecular weight of polyacrylic acid is 240,000; the centrifugation and washing process can be carried out at 15,000 rpm. Centrifuge at low speed and rinse with deionized water.

[0030] When the functionalized graphene is polyethyleneimine functionalized graphene, its preparation is a prior art (Nanoscale, 2013, 5, 663–670).

[0031] As a preferred version, the preparation method of polyallylamine functionalized graphene:

[0032] (1) Add an aqueous solution of polypropylene amine (the average molecular weight of polypropylene amine is 15000) to the GO dispersion, add hydrazine hydrate, and ultrasonically stir at room temperature for 20min-1h to obtain the mixture;

[0033] The mass ratio of described polypropylene amine, graphene oxide and hydrazin...

Embodiment 1

[0059] Preparation of polyallylamine functionalized graphene:

[0060] Add 2.4mL of 58mg / mL polyallylamine aqueous solution (the average molecular weight of polyallylamine is 15000) to 40mL of 0.4mg / mL uniform GO dispersion, add 160μL of hydrazine hydrate, and ultrasonically stir at room temperature for 30min, the resulting mixture React at 140° C. for 4 hours to obtain a black solution. Centrifuge the black solution at a speed of 15,000 rpm and rinse it with deionized water three times to remove excess polyallylamine in the solution to obtain polyallylamine functionalized graphene.

Embodiment 2

[0062] Preparation of polyacrylic acid functionalized graphene:

[0063] Add 3.5mL of 25wt% polyacrylic acid aqueous solution (density 1.09g / mL, average molecular weight of polyacrylic acid is 240000) to 40mL of 0.4mg / mL uniform GO dispersion, add 160μL of hydrazine hydrate, and stir at room temperature for 20min, the resulting mixture React at 140°C for 4 hours to obtain a black solution product. The black solution was centrifuged at a speed of 15,000 rpm and washed three times with deionized water to remove excess polyacrylic acid in the solution to obtain polyacrylic acid functionalized graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com