Method for preparing carbon-coated superparamagnetic ferroferric colloidal spheres

A technology of ferric oxide and superparamagnetism, which is applied in the direction of iron oxide/iron hydroxide, magnetic properties of inorganic materials, oxides of ferrous iron, etc. It can solve the problems of high reaction conditions, complicated process, poor stability, etc. problems, achieve high chemical and colloidal stability, simple process, and overcome the high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1. prepares uniform ferric oxide colloidal ball

[0034] Take 0.3g of ferrocene, dissolve it in 30.0mL of acetone, ultrasonically disperse it, then add 1.5ml of 30% hydrogen peroxide dropwise, stir magnetically at 1000r / min for 30 minutes, and then transfer the solution to a volume of 40ml In an autoclave, seal and heat to 240°C, keep it warm for 72 hours, and then cool to room temperature to obtain a black powdery solid; then wash the sample 3 times with acetone and ethanol to remove residual organic matter in the solid powder; then the solid The powder was dried in a vacuum oven at 40°C for 6 hours to obtain the product.

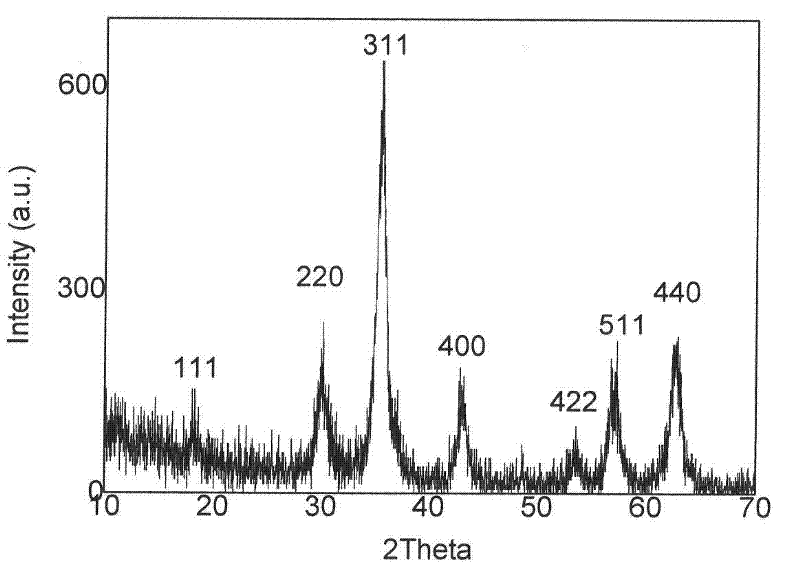

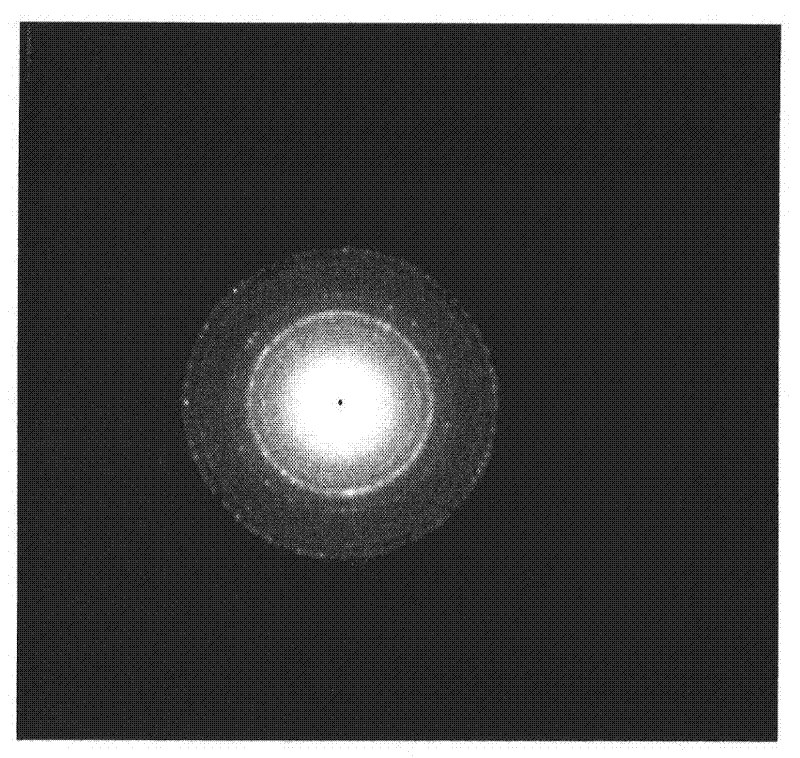

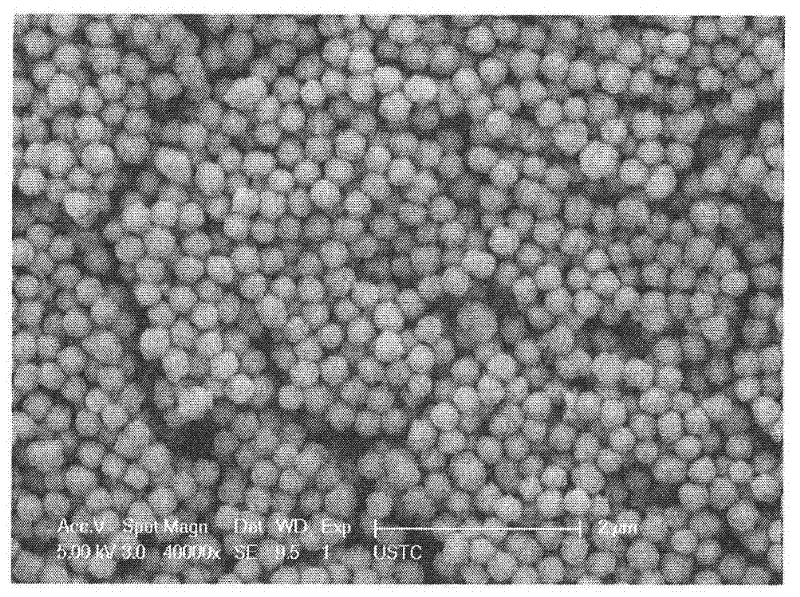

[0035] like figure 1 Shown, according to the X-ray diffraction of present embodiment product Figure, all diffraction peak positions correspond to (111), (220), (311), (222), (400), (422), (511), (440) face of ferric oxide respectively, show product as Ferric oxide; By the transmission electron microscope electron diffraction image of ...

Embodiment 2

[0036] Example 2. Effect of the amount of ferrocene on the product

[0037] Take 0.1g and 0.2g of ferrocene, dissolve them in 30.0mL of acetone, ultrasonically disperse and then add 1.5ml of 30% hydrogen peroxide dropwise, stir magnetically at 1000r / min for 30 minutes, and transfer the solution to In an autoclave with a capacity of 40ml, sealed and heated to 240°C for 72 hours, and then cooled to room temperature to obtain a black powdery solid; then acetone and ethanol were respectively washed the sample 3 times to remove the residual organic matter in the solid powder; then The solid powder was dried in a vacuum oven at 40°C for 6 hours to obtain the product. The appearance of the product is as Figure 8 (0.10g) and Figure 9 (0.20g). Figure 8 and Figure 9 It is shown that the smaller the amount of ferrocene, the smaller the thickness of the carbon layer on the surface of the iron tetroxide nanospheres.

Embodiment 3

[0038] Example 3. Effect of the amount of hydrogen peroxide on the product

[0039] The same solution was prepared in the same way as in Example 1, that is, 0.3g of ferrocene was weighed and dissolved in 30.0ml of acetone, but the amount of hydrogen peroxide added later was changed to 0.5ml, 1.5ml, and 3ml, respectively. , and the other processes are the same. The obtained results were confirmed by X-ray diffraction analysis that they were all colloidal spheres of iron tetroxide. The difference was that colloidal spheres with particle sizes of 90 nm, 150 nm and 200 nm were obtained respectively. A smaller amount of hydrogen peroxide can only obtain small particles with weak magnetic properties, not ferric oxide, and too much hydrogen peroxide has little effect on the change of particle size, so the amount of hydrogen peroxide is usually 0.5ml- between 3ml. The obtained product looks like Figure 10 , Figure 11 and Figure 12 shown. Figure 10 , Figure 11 and Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com