A Method for Determining Installation Parameters of Satellite Orbit Control Engine

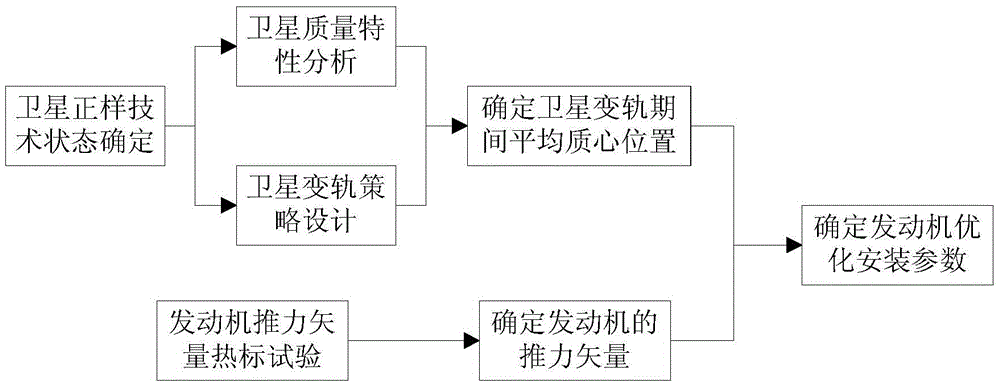

An orbit control engine and determination method technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that the installation orientation is not optimal, save satellite propellant, increase the payload weight, and prolong the in-orbit effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

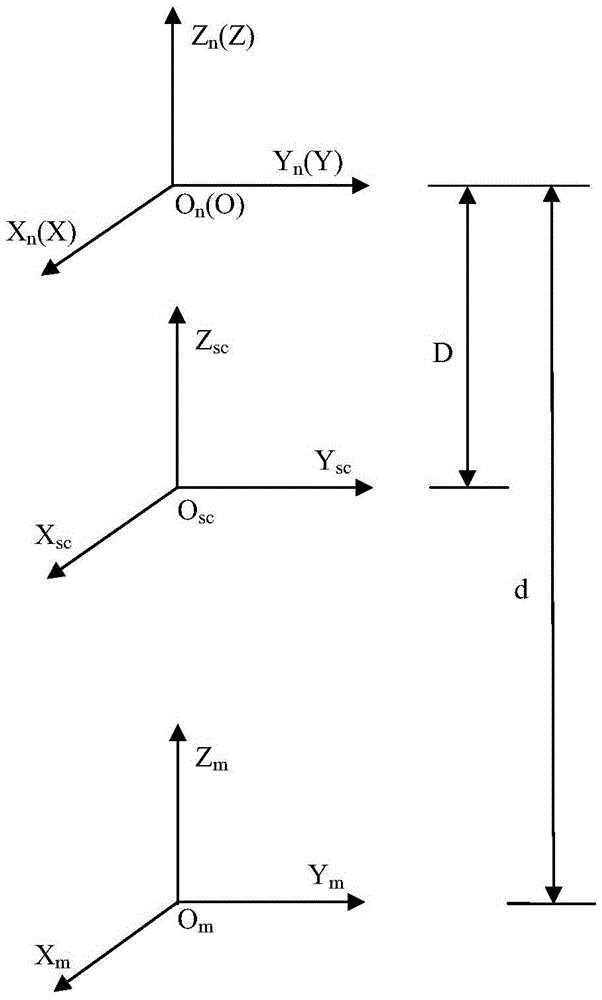

[0011] During the installation process of the satellite orbit control engine, four coordinate systems will be involved, which are the satellite mechanical coordinate system O sc x sc Y sc Z sc , engine installation coordinate system O n x n Y n Z n , the engine body coordinate system OXYZ and the engine precision measuring mirror coordinate system O m x m Y m Z m , their relationship is as figure 1 shown.

[0012] Among them, the engine installation coordinate system O n x n Y n Z n Fixed on the center of the end face of the satellite orbit control engine mounting bracket, and the satellite mechanical coordinate system O sc x sc Y sc Z sc is the translation relationship, and the translation distance is D, that is, the theoretical distance between the lower installation end surface of the engine mounting bracket and the separation surface of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com