Method for studying disinfected recycled water reuse equipment corrosion influence factors

A technology of influencing factors and equipment corrosion, applied in general water supply saving, test water, special data processing applications, etc., can solve problems such as low corrosion rate and equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

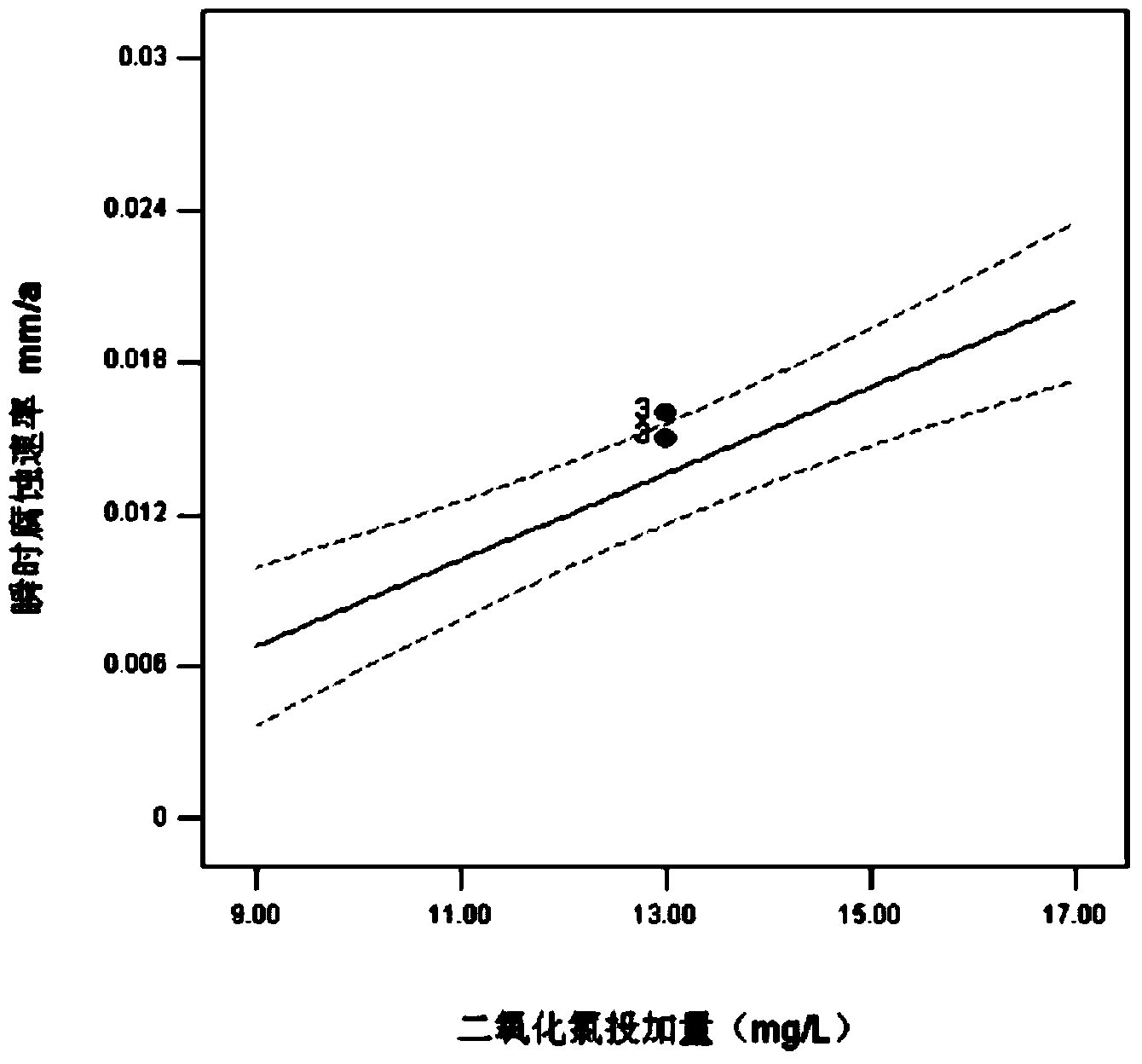

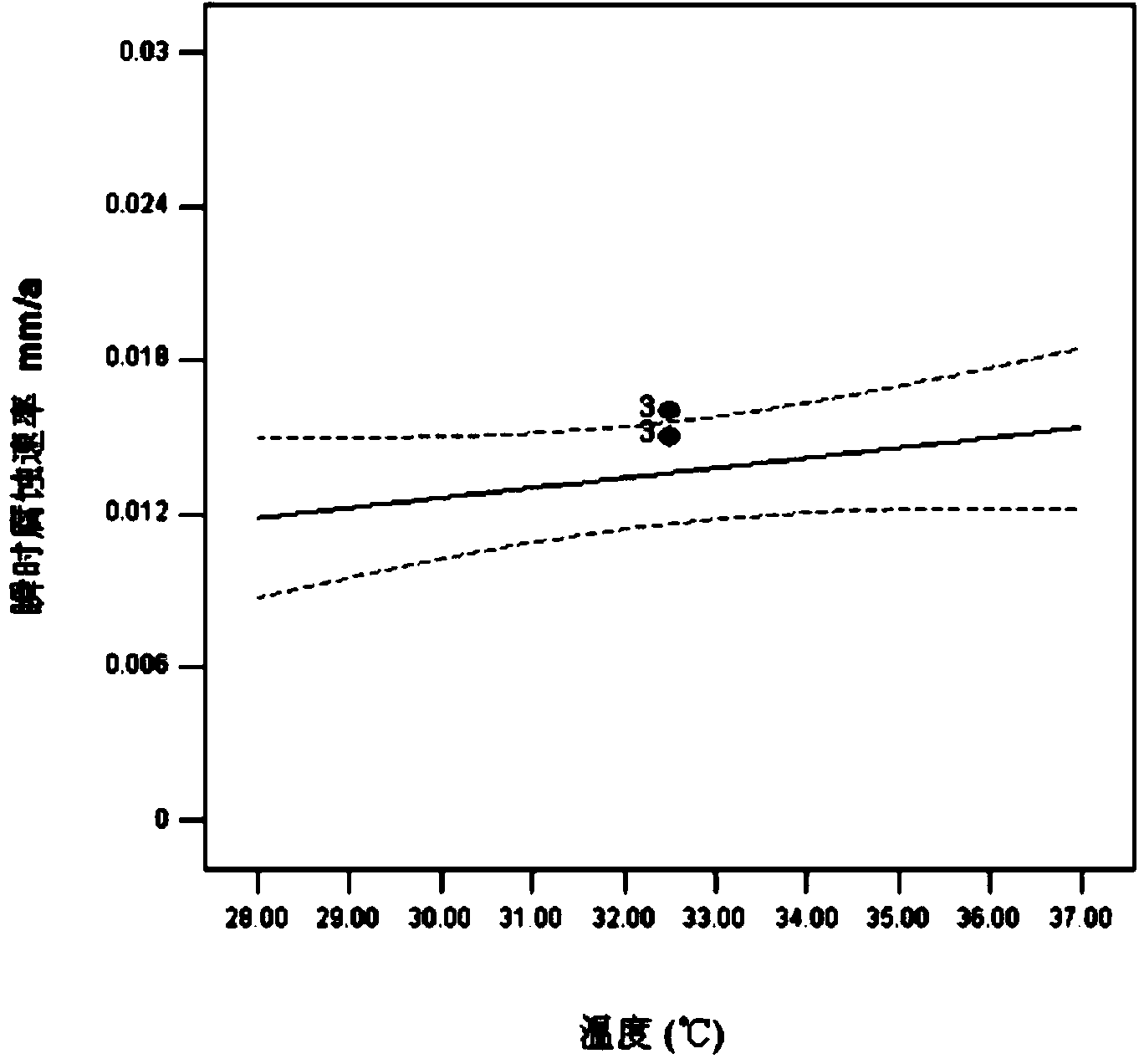

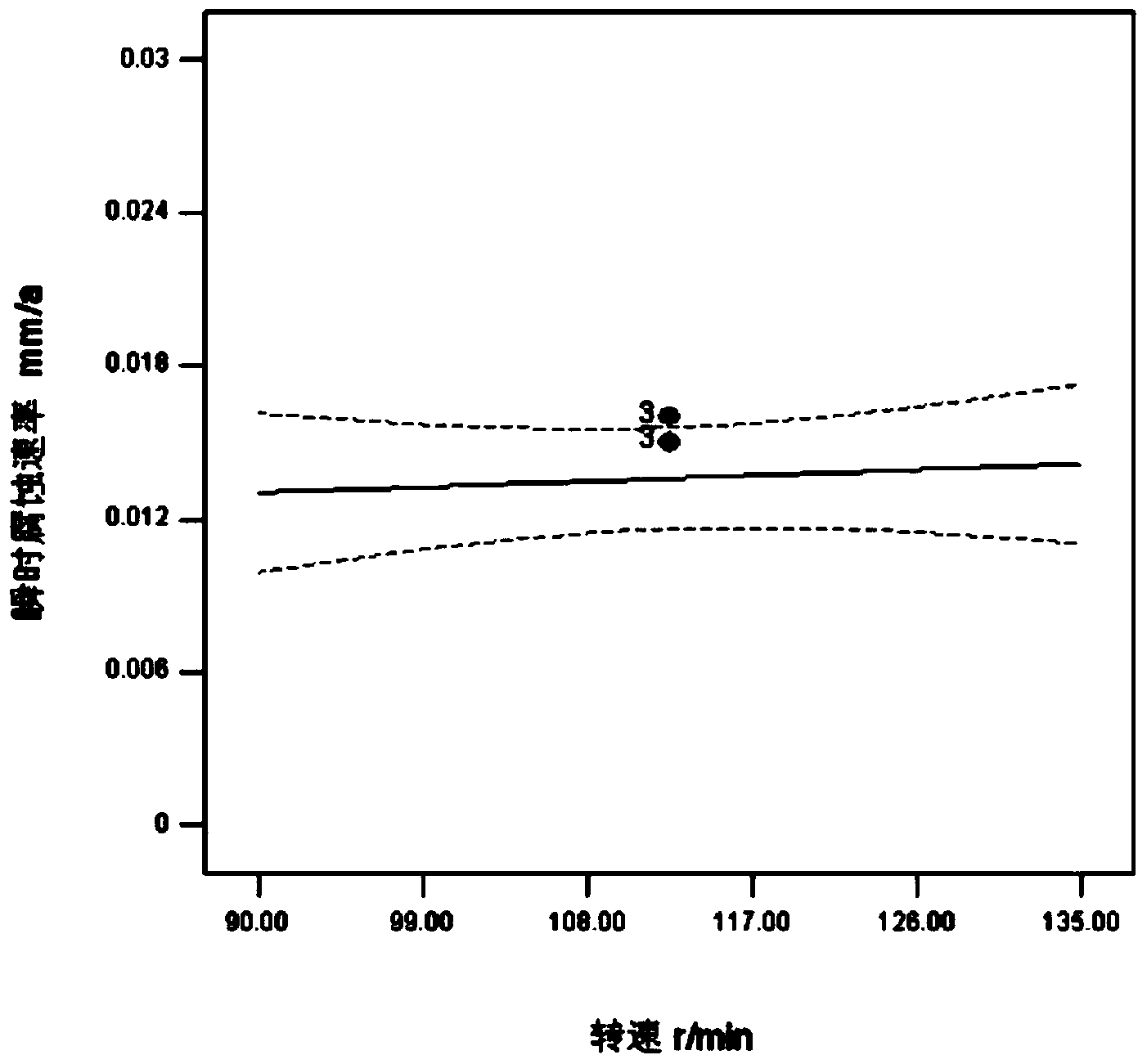

[0041] The present invention provides a method for studying the factors affecting corrosion of reclaimed water reuse equipment after disinfection. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0042] At present, the commonly used disinfectants in reclaimed water reuse include chlorine dioxide, liquid chlorine, ultraviolet rays, ozone, etc., and various disinfection techniques have their own advantages and limitations, among which chlorine disinfection is the most widely used. In the process, the cost is low and the operation is simple, but excessive dosing will produce harmful substances, which will cause corrosion hazards to the water supply pipeline. Therefore, many experts are committed to the research of liquid chlorine disinfection substitutes, among which organic disinfectants have already occupied the field of disinfection In some markets, however, relatively few organic disinfec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com