Transducer calibration method for vehicle weighing system

A calibration method and vehicle weighing technology, which is applied in the field of sensor calibration of vehicle weighing systems, can solve problems such as large data errors, and achieve the effects of easy maintenance, improved weighing accuracy, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments.

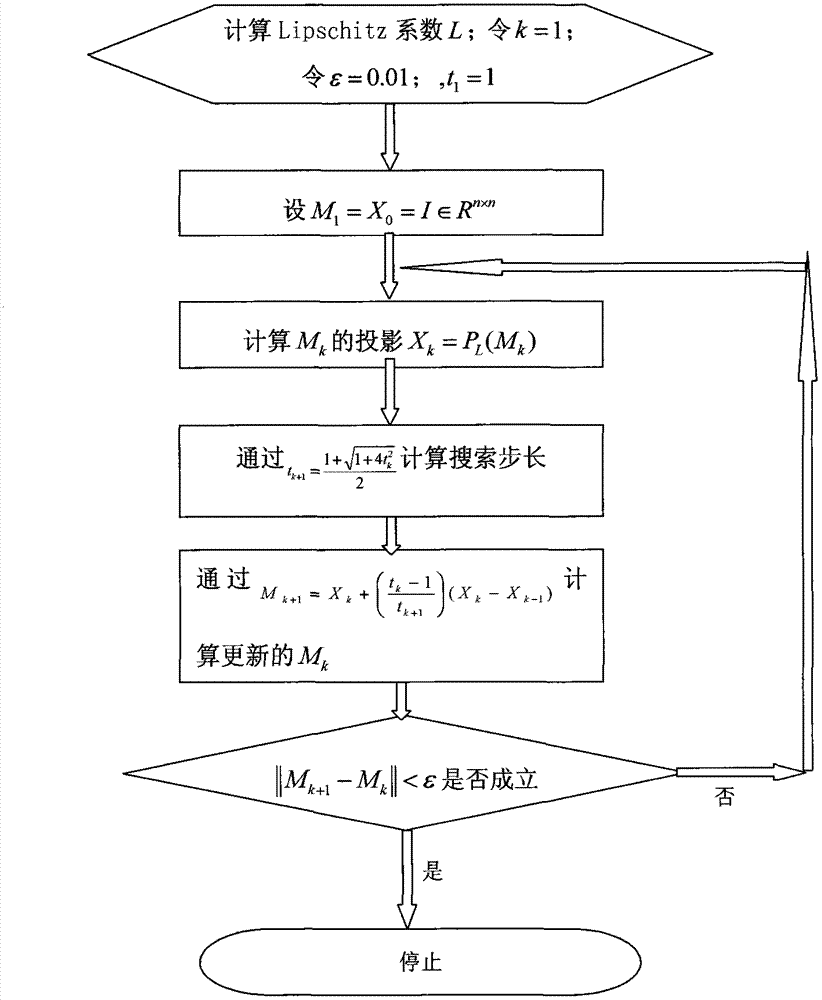

[0031] A design method for an intelligent vehicle weighing system, which includes strain resistance analog sensors, a junction box, and a sensor calibration algorithm, the steps of which are as follows:

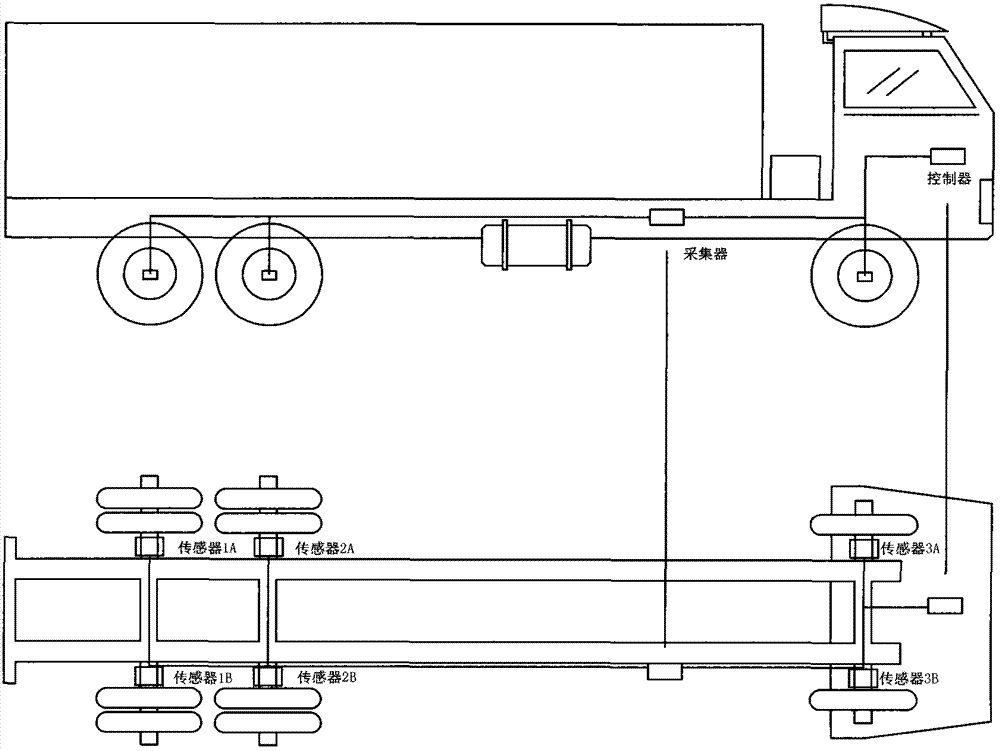

[0032] 1) Reference figure 1 , Weld a sensor at both ends of the car axle; figure 1 Among them, a total of 6 sensors are welded, among which sensor 1A and sensor 1B are welded on the same axle; sensor 2A and sensor 2B are welded on the same axle; sensor 3A and sensor 3B are welded on the same axle superior. When welding, use top-mounted sensors as much as possible. If there is no space to weld top-mounted sensors, use side-mounted sensors;

[0033] 2) Connect the sensor to the data collector with an analog line;

[0034] 3) Calibrate the sensor and store the calibrated parameters in the memory of the main controller and data collector;

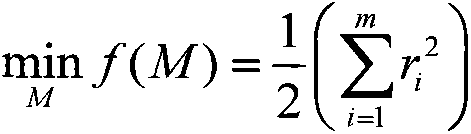

[0035] 4) Calculate the weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com