Disc solar furnace

A solar furnace and dish-type technology, which is applied in the field of solar thermal utilization, can solve the problems of reducing the cost of unit power generation capacity, and the difficulty of reliable connection between the collector and the external medium system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

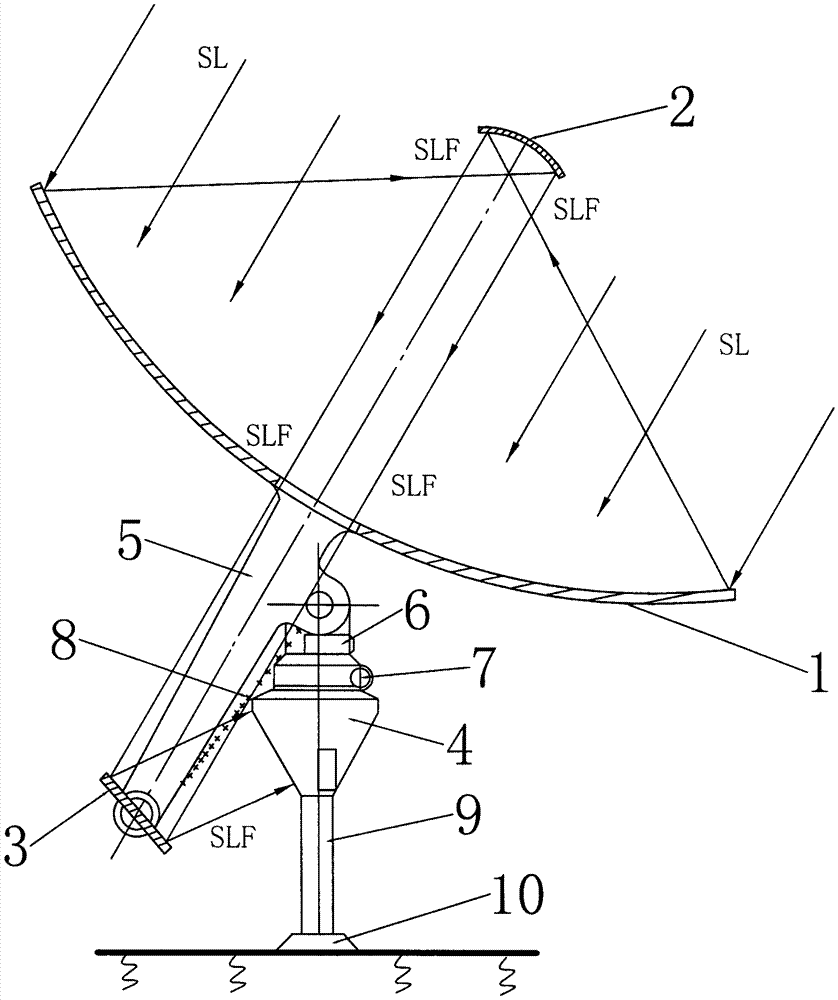

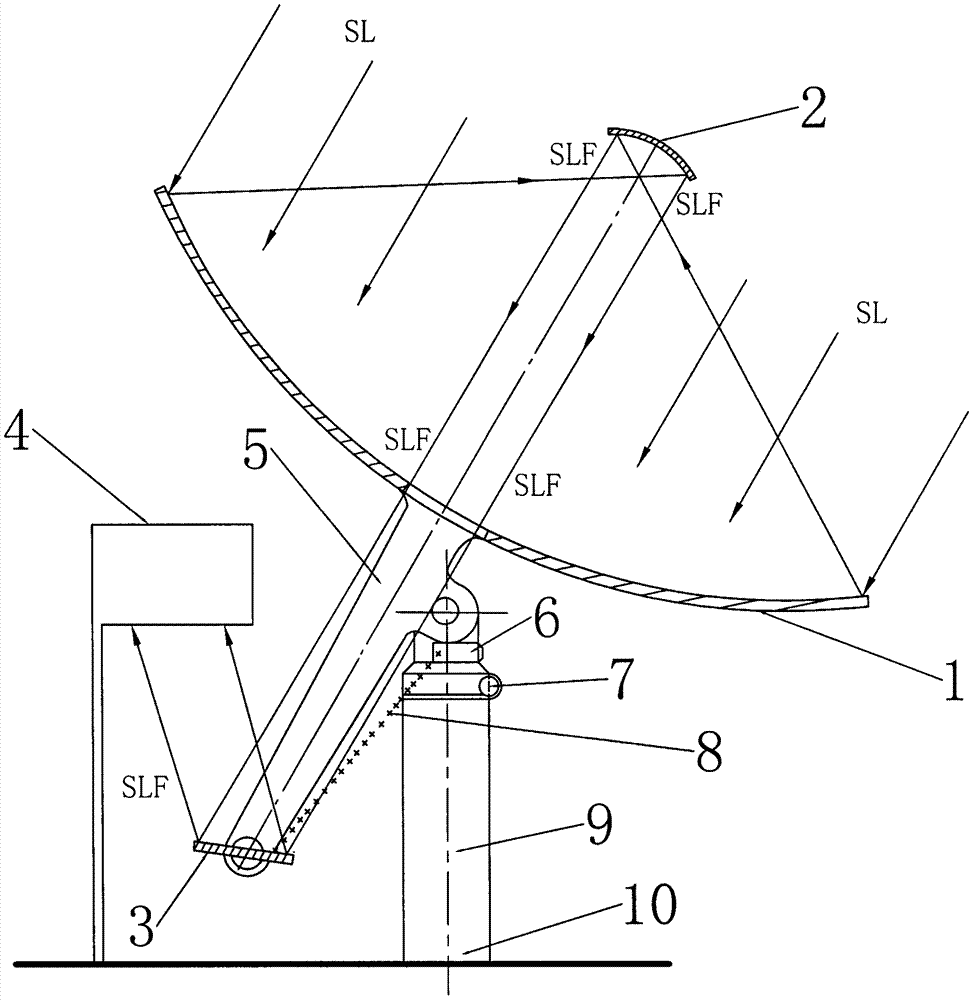

[0012] according to figure 1 and figure 2 According to the structural requirements of the dish solar furnace shown, the concentrating dish (1), reflective cap (2), plane reflector (3), black cavity (4), support arm (5), elevation angle tracking device (6), Horizontal angle tracking device (7), plane mirror transmission mechanism (8), support (9) and base (10), carry out on-site assembly again.

[0013] 1. Condenser (1) is a rotating paraboloid, the relationship between its depth H, diameter D and focal length F is D 2 =16FH. A window is opened in the center of the disc. The structure of laying a parabolic substrate on the skeleton can be adopted, and the concave surface can be made of mirror aluminum as a reflective mirror. The optical disc (1) can also be made into a foldable form according to the folding principle of an umbrella, and can be folded together with other components into a smaller volume for easy travel.

[0014] 2. The reflection cap (2) is also a parabolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com