Rotary guide shoe

A technology of guiding shoes and swivel seats, which is applied in the direction of drilling equipment, earthwork drilling, drill pipes, etc., and can solve the problems of not being able to reduce casing resistance, affecting cementing quality, and having no rotatable structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

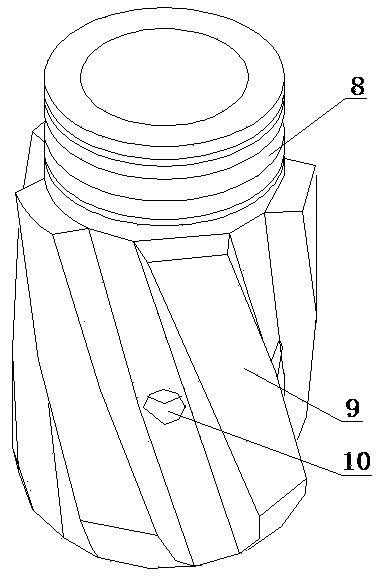

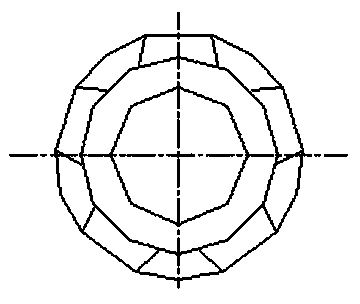

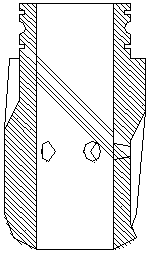

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 The shown rotating shoe includes a rotating base 1 and a guiding end 2 arranged at the lower end of the rotating base 1. The guiding end 2 is a hollow structure, and its outer surface is provided with a plurality of blades 9 inclined from top to bottom. A discharge hole 10 leading to the inside of the guide end 2 is provided between adjacent blades 9; a rotating turbine blade 5 connected through a blade seat 13 is provided inside the guide end 2; the blade seat 13 is arranged on the top of the guide end 2; The center of the blade base 13 is provided with a central hole, and the bottom surface of the blade base 13 is provided with a hollow column coaxial with the central hole. There are at least three rotating turbine blades 5, and the inner ends of the rotating turbine blades 5 are connected to the The hollow column is connected, and the top of the rotating turbine blade 5 is ...

Embodiment 2

[0020] On the basis of Embodiment 1, the blade seat 13 is integrally formed with the leading end 2 or connected through threads. The inner wall of the lower end of the rotating seat 1 is provided with a first ball groove 7, the outer wall of the upper end of the leading end 2 is provided with a second ball groove 8 matching the first ball groove 7, and the surface of the rotating seat 1 is provided with a through hole. Assembly holes 11 for assembling balls to the first ball groove 7 and the second ball groove 8, the first ball groove 7 and the second ball groove 8 contain a plurality of balls 3, and plugs 6 are installed on the assembly holes; A sealing ring 4 is also provided between 1 and the leading end 2, and the sealing ring 4 is located below the first ball groove 7 and the second ball groove 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com