Tool clamp for machining cutting edge of workpiece and operation method of tool clamp

A technology for machining workpieces and fixtures. It is used in the control of workpiece feed motion, manufacturing tools, and grinding workpiece supports. It can solve the problem that the workpiece is not easy to reverse, adjust, clamp and locate a single function, and the waste is not easy to centralize processing, etc. It can improve transmission efficiency and transmission accuracy, facilitate collection, and reduce noise and resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

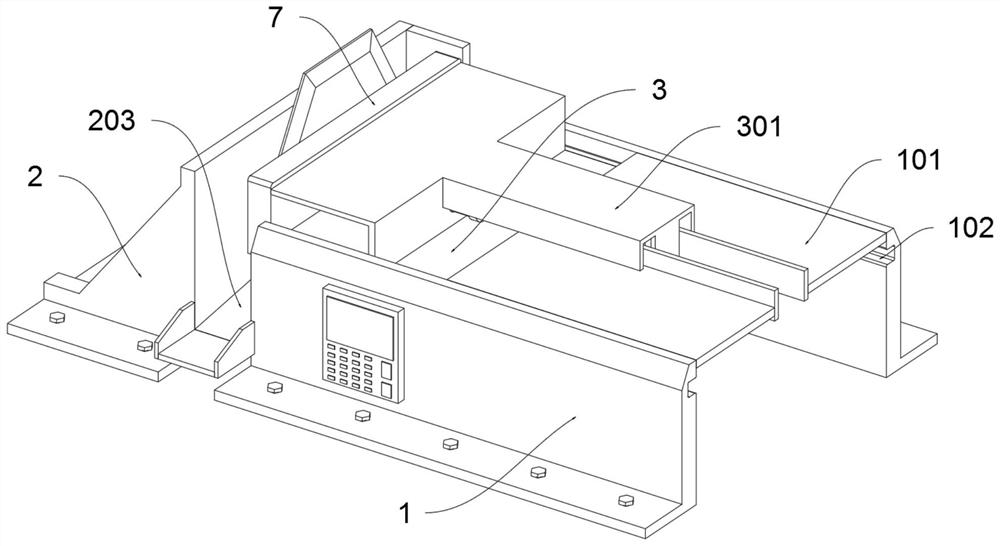

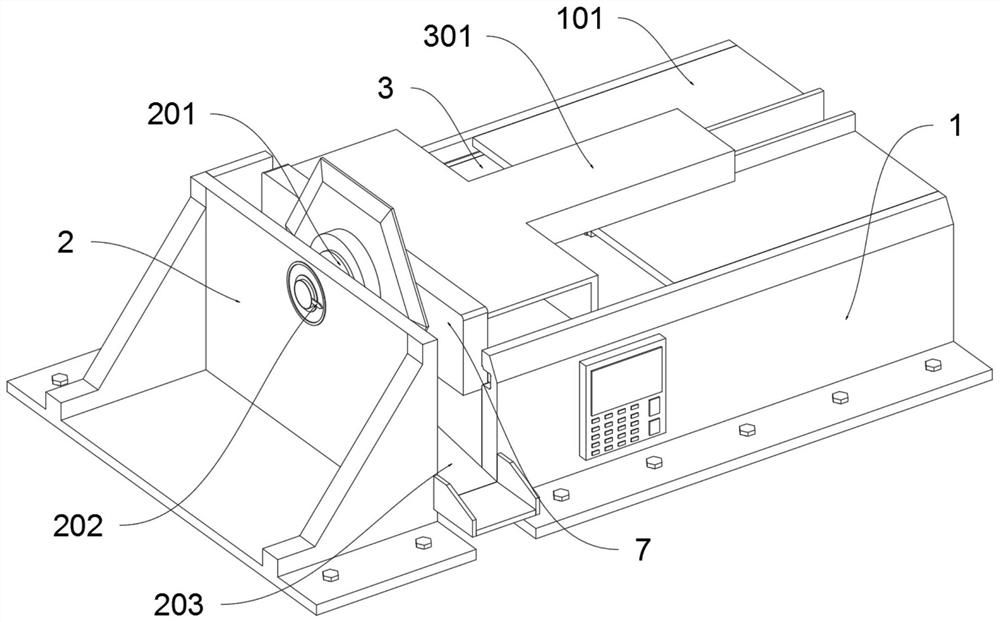

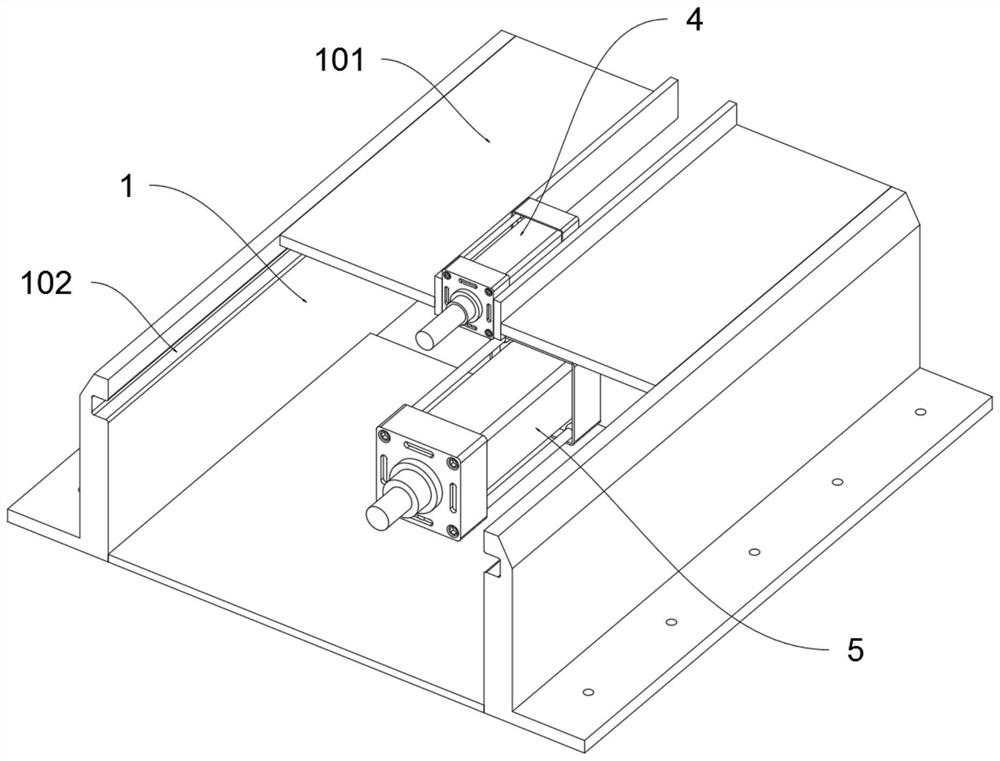

[0034] as attached figure 1 To attach Figure 8 Shown:

[0035] The present invention provides a tooling fixture for processing workpiece cutting edge and its operation method, which comprises an active clamping table 1; a positioning frame 2 is fixedly connected to the left side of the active clamping table 1; In the middle; the reversing pusher 4 is fixedly connected to the top of the active clamping table 1 by screws; the clamping pusher 5 is fixedly connected to the bottom plate of the active clamping table 1 by screws, and the output rod of the clamping pusher 5 is connected and driven to move The bottom of the push frame 3; the top frame 6 is fixedly connected to the output push rod of the reversing pusher 4; the positioning pressure plate 7 is fixedly connected to the left end of the movable push frame 3; the rotary drive member 8 is fixedly connected to the lower surface of the upper baffle plate 301 , and the rotary drive member 8 is connected and drives the top fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com