Disperse and reactive printing method for polyester-cotton fabric

A technology for dispersing active polyester-cotton fabrics, applied in the field of textile printing, which can solve problems such as cloth surface dullness, fabric yellowing, and lower dyeing performance, and achieve the effects of environmental protection, stable color paste, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

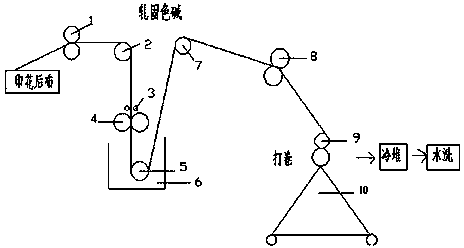

Method used

Image

Examples

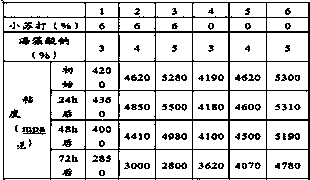

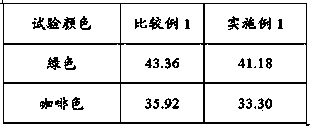

Embodiment 1

[0048] Weighing: Wuxi Zhenyang Reactive Red K-2BP 8kg, Reactive Orange K-GN 10kg, Reactive Black K-BR 30kg; Zhejiang Longsheng Disperse Red S-2G 8kg, Disperse Orange S-4RL 10kg, Disperse Black S-2BL 30kg Put it into a bucket, add an appropriate amount of room temperature water to make the dye into a paste, then add an appropriate amount of hot water at 70°C, and stir until the dye is fully melted, and the dye solution is transparent and free of particles. Then weigh 210kg of sodium alginate paste, and finally add the dye solution into the paste and stir until uniform and free of lumps. Measure its viscosity, the viscosity after fine-tuning is 3000mpa.s. Then add 7.5kg of dissolved anti-staining salt S and 5kg of chelating agent CM-5 to obtain a brown color paste, add water to make the total mass of the brown color paste 500kg, then filter for subsequent use.

[0049] Weighing: Wuxi Zhenyang Active Green Blue K-GL 17kg, Active Yellow K-RN 20kg, Active Black K-BR 22kg; Zhejiang...

Embodiment 2

[0068] Weighing: Wuxi Zhenyang Active Cuilan K-GL 6kg, Active Bright Yellow K-4G 10kg; Zhejiang Longsheng Disperse Blue S-GL 6kg, Disperse Bright Yellow 6GSL 10kg into a bucket, add appropriate amount of room temperature water to prepare the dyes Make a paste, then add an appropriate amount of hot water at 70°C, stir until the dye is fully dissolved, and the dye solution is transparent and free of particles. Then weigh 210kg of sodium alginate paste, and finally add the dye solution into the paste and stir until uniform and free of lumps. Measure its viscosity, the viscosity after fine-tuning is 3000mpa.s. Then add 7.5kg of dissolved anti-dyeing salt S and 5kg of chelating agent CM-5 to obtain a grass-green color paste, add water to make the total mass of the grass-green color paste 500kg, then filter for later use.

[0069] Weigh: Wuxi Zhenyang Active Active Bright Red K-2G 25kg; Zhejiang Longsheng Disperse Red 2GH 25kg into the bucket, add an appropriate amount of room temp...

Embodiment 3

[0088] Weigh: Wuxi Zhenyang Reactive Red K-2BP 1kg, Reactive Orange K-GN 16kg; Zhejiang Longsheng Disperse Red S-2G 1kg, Disperse Orange S-4RL 16kg into the bucket, add an appropriate amount of room temperature water to dissolve the dye Make it into a paste, then add an appropriate amount of hot water at 70°C, stir until the dye is fully dissolved, and the dye solution is transparent and free of particles. Then weigh 210kg of sodium alginate paste, and finally add the dye solution into the paste and stir until uniform and free of lumps. Measure its viscosity, the viscosity after fine-tuning is 3000mpa.s. Then add 7.5kg of dissolved anti-staining salt S and 5kg of chelating agent CM-5 to obtain an orange color paste, add water to make the total mass of the orange color paste 500kg, then filter for subsequent use.

[0089] Weighing: Wuxi Zhenyang Reactive Red K-2BP 3kg, Reactive Yellow K-RN 8kg, Reactive Black K-BR 30kg; Zhejiang Longsheng Disperse Red S-2G 3kg, Disperse Yellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com