Zirconium dispersoid gel complex oil displacing system and preparing method thereof

一种复合驱油、驱油方法的技术,应用在化学仪器和方法、开采流体、土方钻采等方向,能够解决未考虑提高驱油剂洗油效率、混合表面活性剂成份复杂、聚合物流度控制能力弱等问题,达到避免不利影响、良好老化稳定性、提高驱油效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

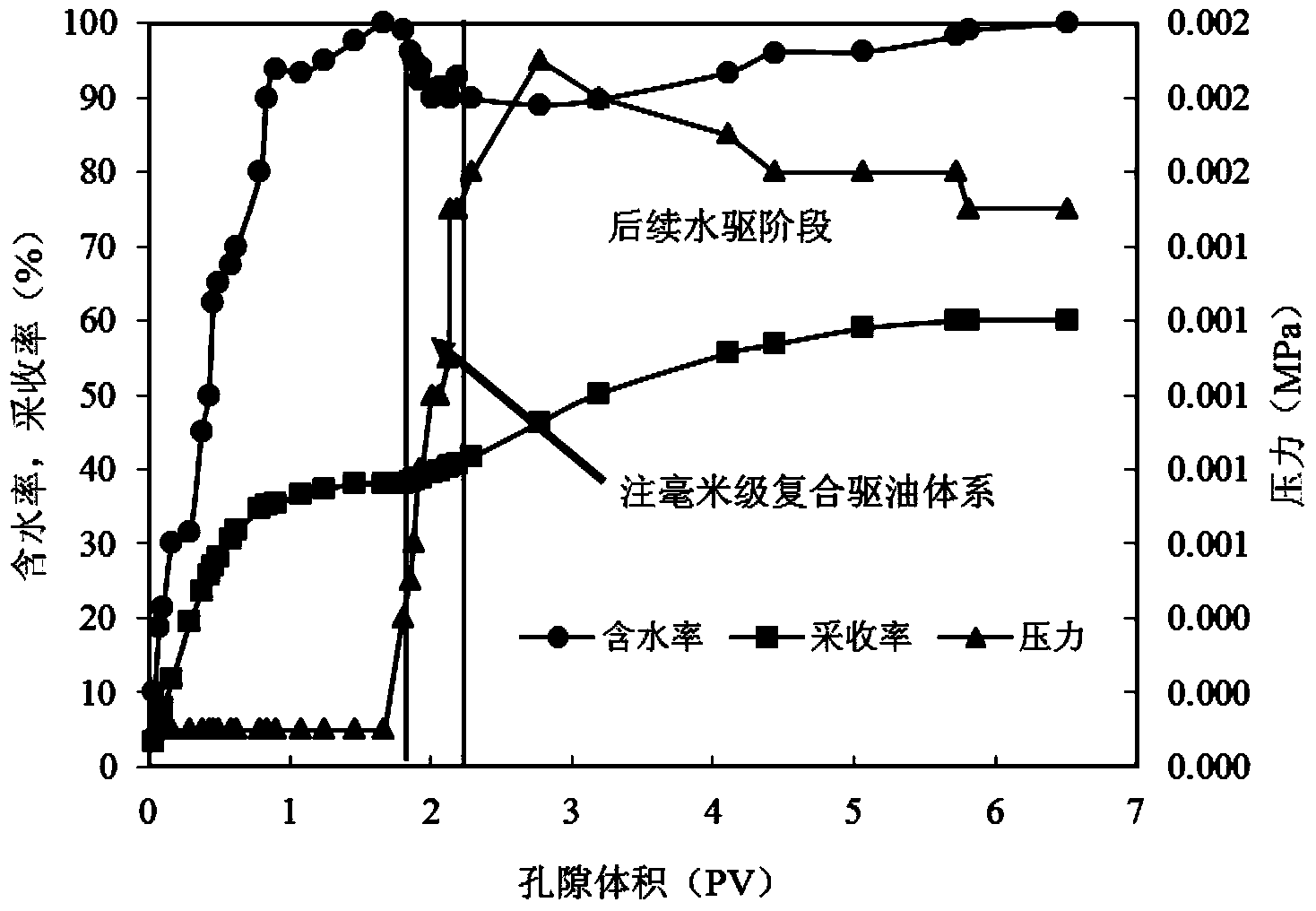

[0039] The preparation method of the above-mentioned zirconium jelly dispersion composite oil displacement system comprises the following steps:

[0040] At room temperature (20±5°C), add one of the nanoscale, micronscale or millimeter-scale zirconium jelly dispersions to the liquid preparation water, stir for 5 minutes until it is uniformly dispersed; then add polyether-type nonionic surfactant Stir for 5 minutes until it is fully dissolved. In the zirconium jelly dispersion composite oil displacement system, the mass fraction of the zirconium jelly dispersion is 0.16% to 0.24%, and the mass fraction of the surfactant is 0.1% to 0.4%. , so as to obtain the composite flooding system of zirconium jelly dispersion.

[0041]An oil displacement method, when the water content of the oil well corresponding to the water injection well increases significantly, the water flooding is inefficient or ineffective and the development effect becomes poor, and a large amount of remaining oil ...

Embodiment 1

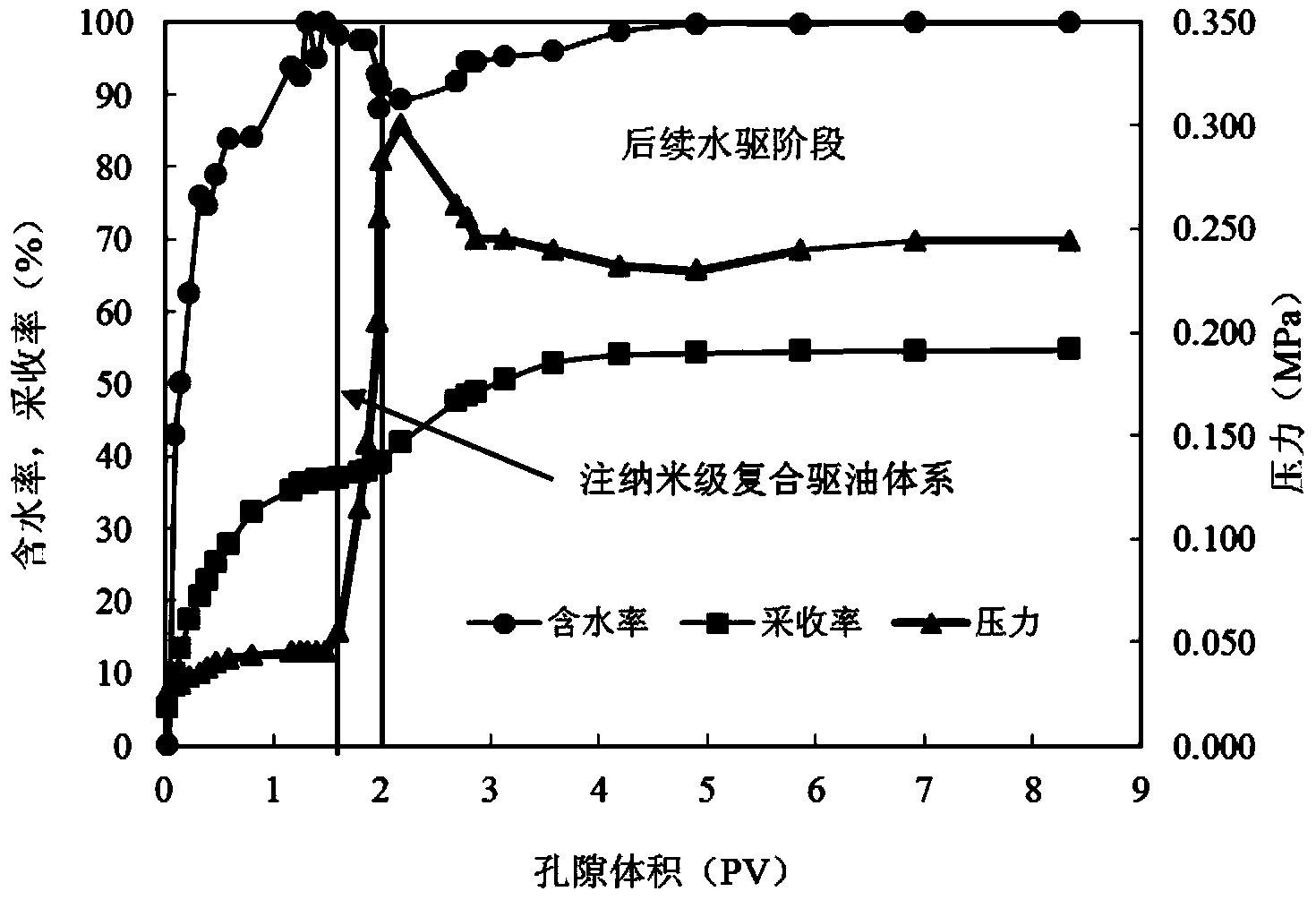

[0051] This example provides the preparation method and oil displacement method of the nano-scale zirconium jelly dispersion composite oil displacement system.

[0052] Nanoscale zirconium jelly dispersion composite oil displacement system, including: nanoscale zirconium jelly dispersion, mass fraction is 0.24%; polyether type nonionic surfactant, mass fraction is 0.1%; The fraction is 99.66%, and the sum of the mass fractions of each component is 100%.

[0053] At room temperature (20±5°C), add 0.24g of nano-sized zirconium jelly dispersion (particle size: 108nm) and 0.1g of polyether-type nonionic surfactant in sequence while stirring in 99.66g of clear water, and stir evenly for 5 The complex oil displacement system of zirconium jelly dispersion was formulated in minutes, and the composite oil displacement system reduced the interfacial tension of oil and water by 2.4135×10 -3 mN / m.

[0054] This example provides the oil displacement method of the nano-scale zirconium jel...

Embodiment 2

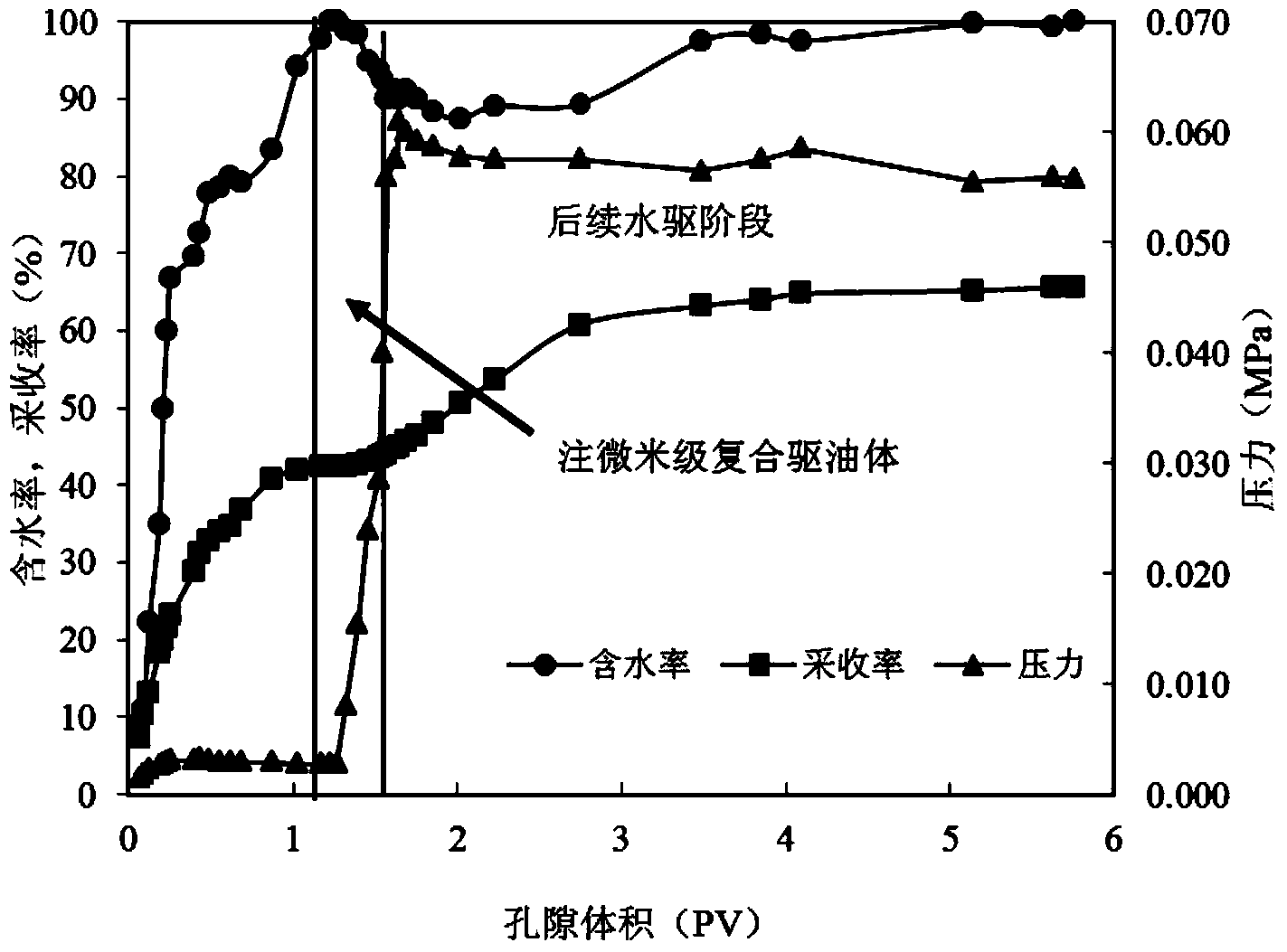

[0060] This example provides the preparation method and oil displacement method of the composite oil displacement system of micron-sized zirconium jelly dispersion.

[0061] Micron-sized zirconium jelly dispersion composite oil displacement system, including: micron-sized zirconium jelly dispersion, the mass fraction is 0.2%; polyether type nonionic surfactant, the mass fraction is 0.3%; The fraction is 99.5%, and the sum of the mass fractions of each component is 100%.

[0062] At room temperature (20±5°C), add 0.2g of micron-sized zirconium jelly dispersion (particle size: 5.6μm) and 0.3g of polyether-type nonionic surfactant in 99.5g of clear water while stirring, and stir evenly The composite oil displacement system of micron-sized zirconium jelly dispersion was prepared in 5 minutes, and the composite oil displacement system reduced the oil-water interfacial tension by 1.6352×10 -3 mN / m.

[0063] This example provides the oil displacement method of the micron-sized zirc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com