Compound saltwater drilling fluid for plugging fractures of coal seam

A brine drilling fluid and drilling fluid technology, applied in the field of oil drilling, can solve the problems of coal seam mechanical damage, less plugging particles, construction measures and construction parameters are not in place, etc., to improve the success rate, reduce complexity, single well construction The effect of cycle shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

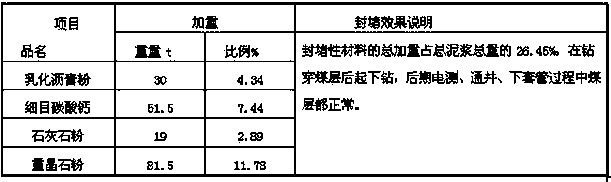

[0019] A composite brine drilling fluid for sealing coal seam fissures, which is composed of the following components and their mass percentages: 7.44% fine calcium carbonate, 4.34% emulsified asphalt powder, 11.78% barite, and 2.89% limestone powder , carboxymethyl starch is 3.5%, sodium formate is 9%, industrial salt is 5%, potassium chloride is 3%, polyanionic cellulose is 0.7%, and the remaining components are clear water; the emulsified asphalt, fine calcium carbonate , barite and limestone powder are collectively referred to as plugging materials. The preparation method is as follows: polyanionic cellulose, carboxymethyl starch, emulsified asphalt powder, fine-mesh calcium carbonate, sodium formate, industrial salt, potassium chloride, limestone powder, and barite are mixed into clear water and stirred evenly. The particle size of the fine-mesh calcium carbonate is 10 μm, the particle size of the emulsified asphalt powder is 5 μm, the particle size of the barite is 50 μm...

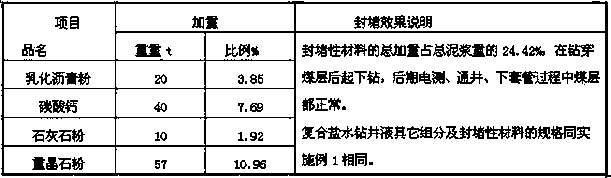

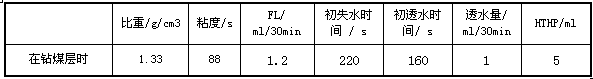

Embodiment 2

[0021] A composite brine drilling fluid for sealing coal seam fissures, which is composed of the following components and their mass percentages: 6% fine calcium carbonate, 4% emulsified asphalt powder, 10% barite, and 2% limestone powder , carboxymethyl starch is 3%, sodium formate is 8%, industrial salt is 4%, potassium chloride is 2%, polyanionic cellulose is 0.6%, and all the other components are clear water, and the particle size of described detailed calcium carbonate is 1 μm, the particle size of emulsified asphalt powder is 0.1 μm, the particle size of barite is 10 μm, and the particle size of limestone powder is 20 μm. Others are with embodiment 1.

Embodiment 3

[0023] A composite brine drilling fluid for sealing coal seam fissures, which is composed of the following components and their mass percentages: 8% fine calcium carbonate, 6% emulsified asphalt powder, 12% barite, and 4% limestone powder , carboxymethyl starch is 4%, sodium formate is 10%, industrial salt is 6%, potassium chloride is 4%, polyanionic cellulose is 0.8%, and all the other components are clear water, and the particle size of described detailed calcium carbonate is 20μm, the particle size of emulsified asphalt powder is 10μm, the particle size of barite is 100μm, and the particle size of limestone powder is 160μm. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com