Method for recovery of carbon fiber by use of low temperature molten salt

A technology for recycling carbon fiber and carbon fiber, which is applied in the field of carbon fiber reinforced polymer recycling carbon fiber, which can solve problems such as pollution, polymer dissolution or cracking, and low temperature, and achieve the effect of simple and easy control of the process and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

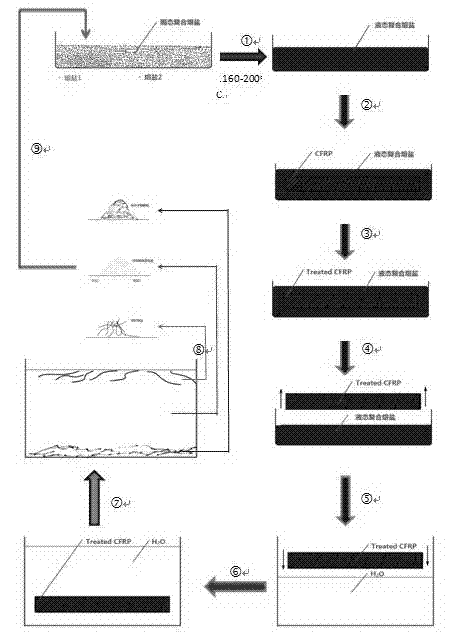

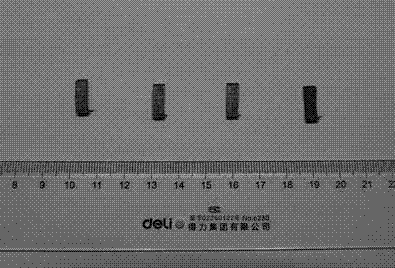

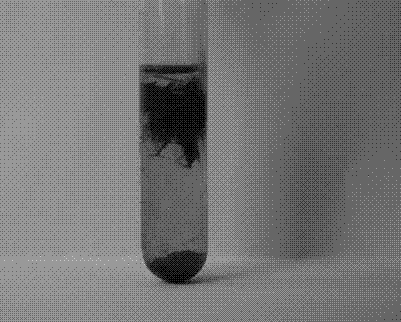

[0027] according to figure 1 The flow chart in the recovery of carbon fiber, specifically: Weigh 2.41g KCl powder and 7.73 g AlCl 3 After mixing well, grind and put the powder into a 30mL crucible. Place the crucible in a muffle furnace and heat it to 200°C, take a 13mm*4mm*3mm carbon fiber reinforced polymer material into it, and keep it warm for 0.5 hours. Then the processed carbon fiber reinforced polymer material is taken out of the crucible, added to a beaker filled with water, and left to stand for 2 hours after ultrasonic treatment for 30 minutes. The carbon fiber is separated from the resin and suspended in water, such as image 3 shown. The separated carbon fibers are clamped out with tweezers, washed and dried to obtain carbon fiber products, such as Figure 6 shown.

Embodiment 2

[0029] according to figure 1 The flow chart in the carbon fiber recovery, specifically: Weigh 2.29 g NaCl powder and 7.98 g AlCl 3 After mixing well, grind and put the powder into a 30mL crucible. Put the crucible in a muffle furnace and heat it to 220°C, take a 13mm*4mm*3mm carbon fiber polymer reinforcement material into it, and keep it warm for 1.0 hour. Then the processed carbon fiber reinforced polymer material is taken out of the crucible, added to a beaker filled with water, and left to stand for 2 hours after ultrasonic treatment for 30 minutes. The carbon fiber is separated from the resin and suspended in water, such as Figure 4 shown. The separated carbon fibers are clamped out with tweezers, washed and dried to obtain carbon fiber products, such as Figure 6 shown.

Embodiment 3

[0031] according to figure 1 The flow chart in the recycling carbon fiber is specifically: Weigh 5.22g ZnCl 2 and 4.86 g AlCl 3 After mixing evenly, grind, then put the mixed powder into a 30mL crucible, place the crucible in a muffle furnace and heat it to 200°C, take a piece of carbon fiber polymer reinforcement material of 13mm*4mm*3mm, and keep it warm for 1.0 Hour. Then the processed carbon fiber reinforced polymer material is taken out of the crucible, added to a beaker filled with water, and left to stand for 2 hours after ultrasonic treatment for 30 minutes. The carbon fiber is separated from the resin and suspended in water, such as Figure 5 shown. The separated carbon fibers are clamped out with tweezers, washed and dried to obtain carbon fiber products, such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com