Method for extracting and separating cytisine

A separation method, the technology of cytisine, applied in the direction of organic chemistry, etc., can solve the problems of low purity, high cost and long cycle of separating cytisine, and achieve the effect of raw material source method, simple operation and simple regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

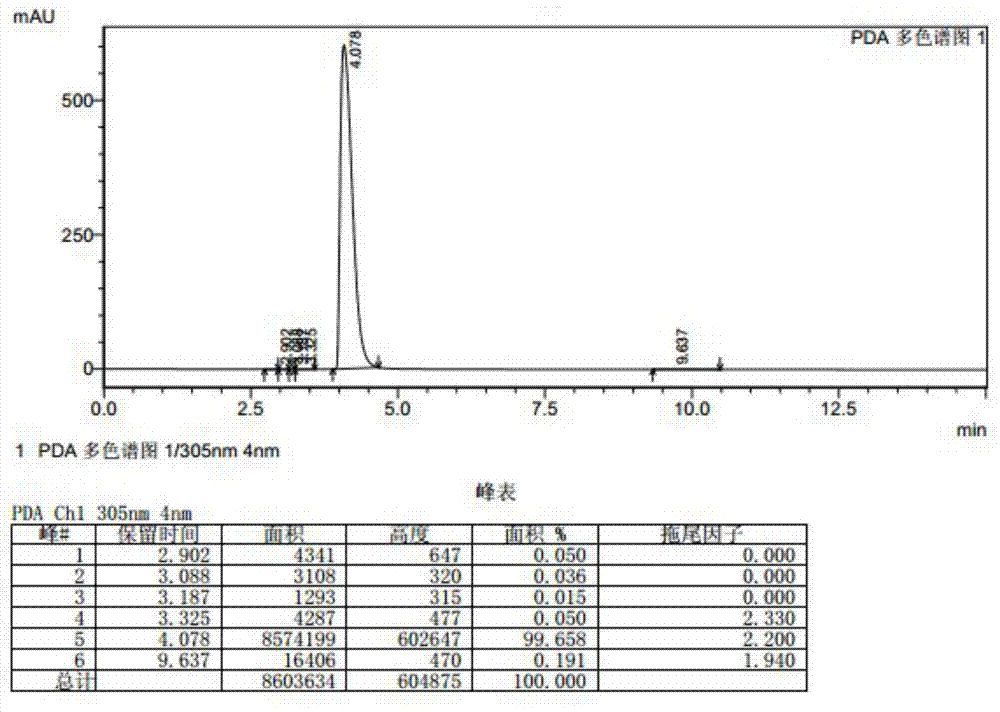

Embodiment 1

[0027] Take 100kg of the raw material of the herbaceous bean and grind it, pass the raw material obtained through the above-mentioned treatment through a 10-mesh sieve, and use 8 times the mass of ethanol with a concentration of 95% to reflux and extract for 1 hour to obtain an extract. Concentrate the extract to a mass concentration of 1.0g / mL, adjust the pH to 8.0, and put it on a pretreated X-5 macroporous resin column (315×1500mm), with a sample volume of 0.1 times the column volume, let it stand for 30min, and then Elute with 8 times column volume of pure water and 8 times column volume of 10% ethanol aqueous solution, the elution rate is 1.0mL / min, collect the 10% ethanol eluate, and then concentrate to a mass concentration of 1.0g / mL, Adjust the pH to 9.0, put on the pretreated DM18 macroporous resin column (315×1500mm), the loading volume is 0.1 times the column volume, let stand for 30min, then use 5 times the column volume of pure water, 5 times the column volume of ...

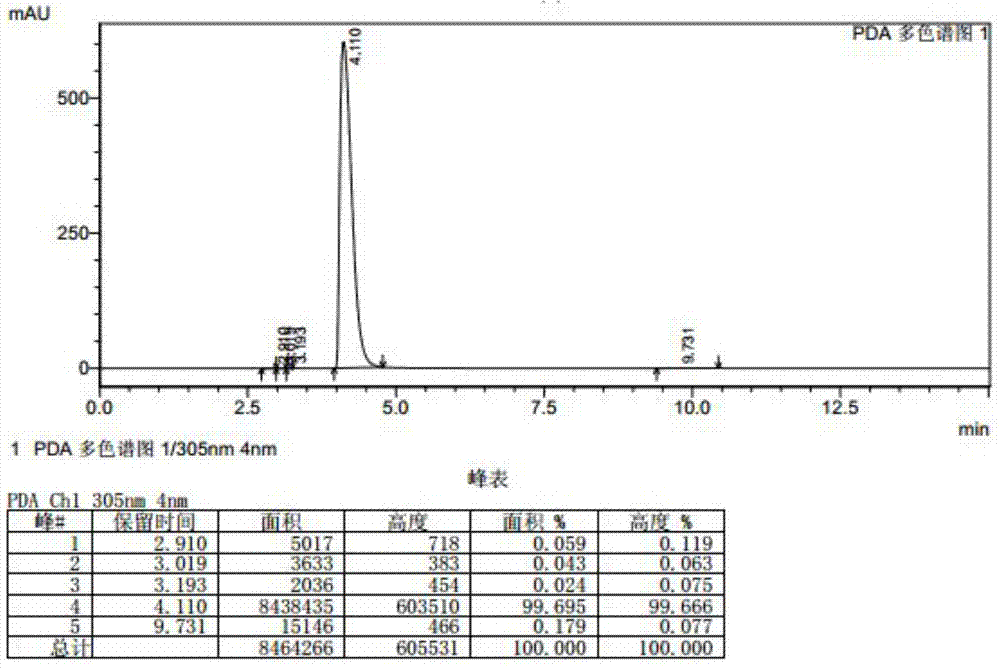

Embodiment 2

[0049]Take 100 kg of the raw material of the herbaceous bean and grind it, pass the raw material obtained from the above-mentioned treatment through a 20-mesh sieve, and use 10 times the amount of methanol with a concentration of 35% to reflux extract for 3 hours to obtain an extract. Concentrate the extract to a mass concentration of 0.5g / mL, adjust the pH to 9.0, and put it on a pretreated AB-8 macroporous resin column (315×1500mm), with a sample volume of 0.2 times the column volume, let it stand for 50min, and then Use 10 times column volume of pure water and 10 times column volume of 30% ethanol aqueous solution to elute, the elution rate is 3mL / min, collect the 30% ethanol eluate, then concentrate to a mass concentration of 0.5g / mL, adjust pH to 8.0, on the pretreated DM18 macroporous resin column (315 × 1500mm), the sample volume is 0.2 times the column volume, let stand for 20min, and then use 6 times the column volume of pure water, 6 times the column volume of 10 % e...

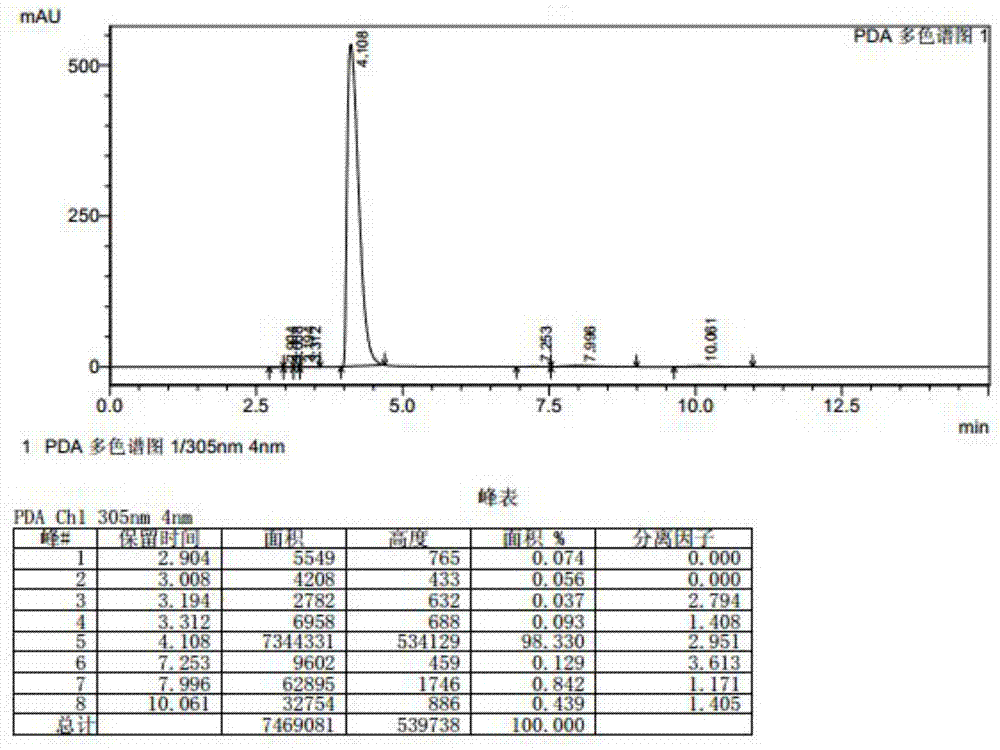

Embodiment 3

[0071] Take 100 kg of the raw material of the herba bean and grind it, pass the raw material obtained from the above treatment through a 60-mesh sieve, and reflux extract with 4 times the amount of ethanol with a concentration of 65% for 4 hours to obtain an extract. Concentrate the extract to a mass concentration of 1.5g / mL, adjust the pH to 8.5, and put it on a pretreated X-5 macroporous resin column (315×1500mm), with a sample volume of 0.01 times the column volume, let it stand for 10min, and then Elute with 5 times column volume of pure water and 5 times column volume of 40% ethanol aqueous solution, the elution rate is 5mL / min, collect the 40% ethanol eluate, then concentrate to a mass concentration of 1.5g / mL, adjust pH to 8.5, on the pretreated DM2 macroporous resin column (315 × 1500mm), the sample volume is 0.01 times the column volume, let stand for 40min, followed by 4 times the column volume of pure water, 4 times the column volume of 10 % ethanol water solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com