Winding-up and roll-replacing device of wide-width thin films

A film and wide-width technology, which is applied in the field of rewinding and changing devices for wide-width films, can solve problems such as difficult bottoming, loss of tension, and large width, and achieve the effect of improving the quality of bottoming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

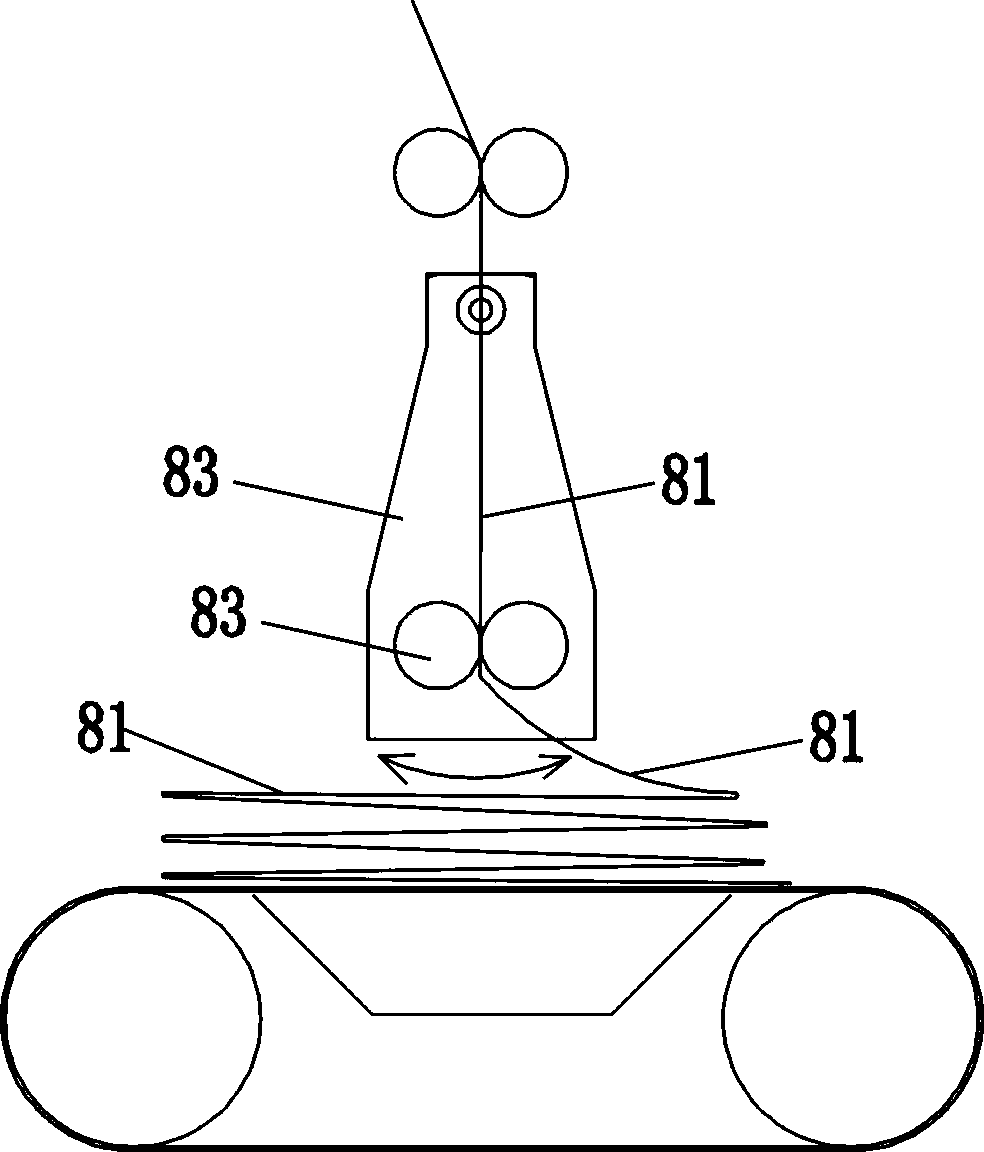

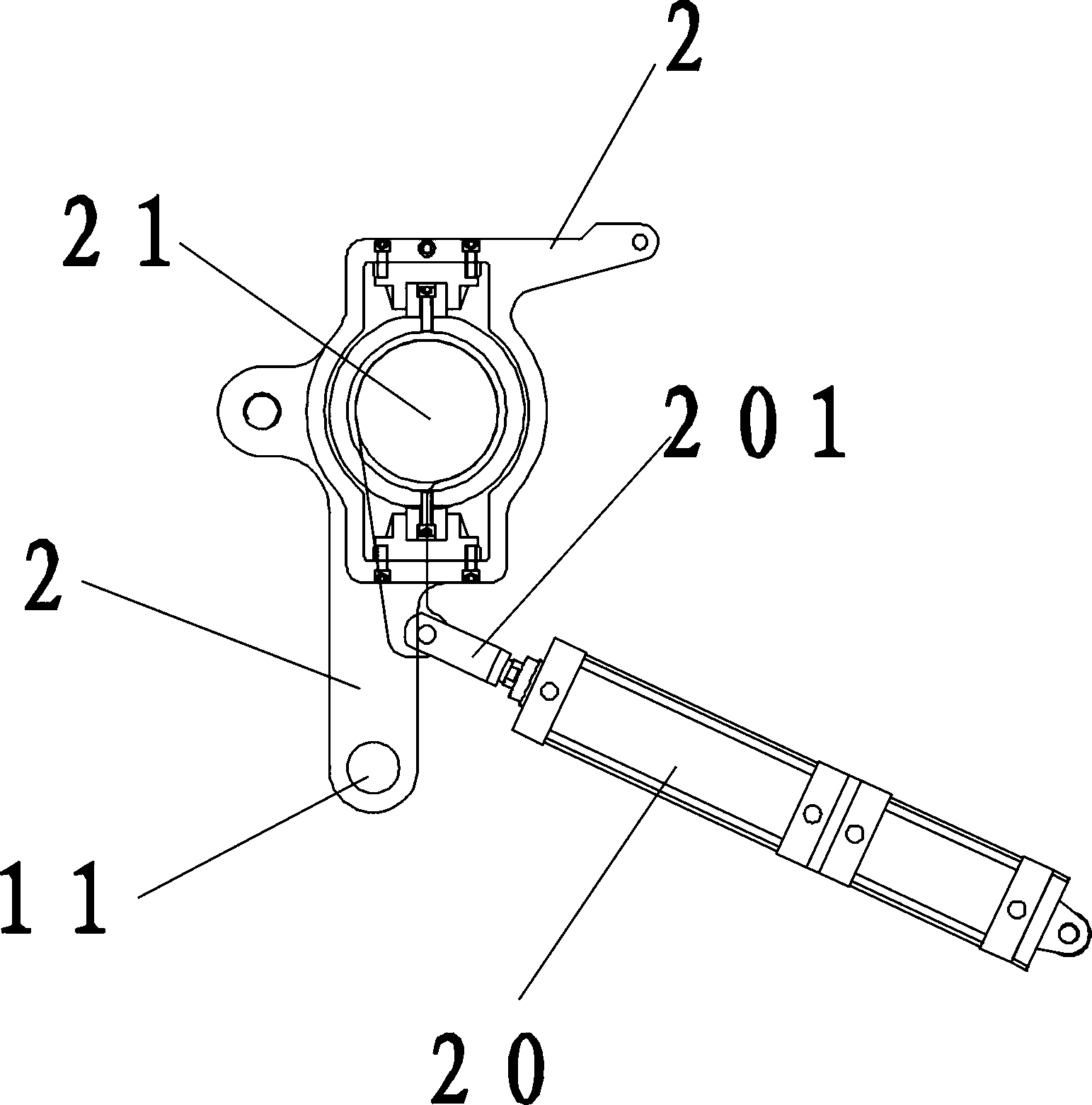

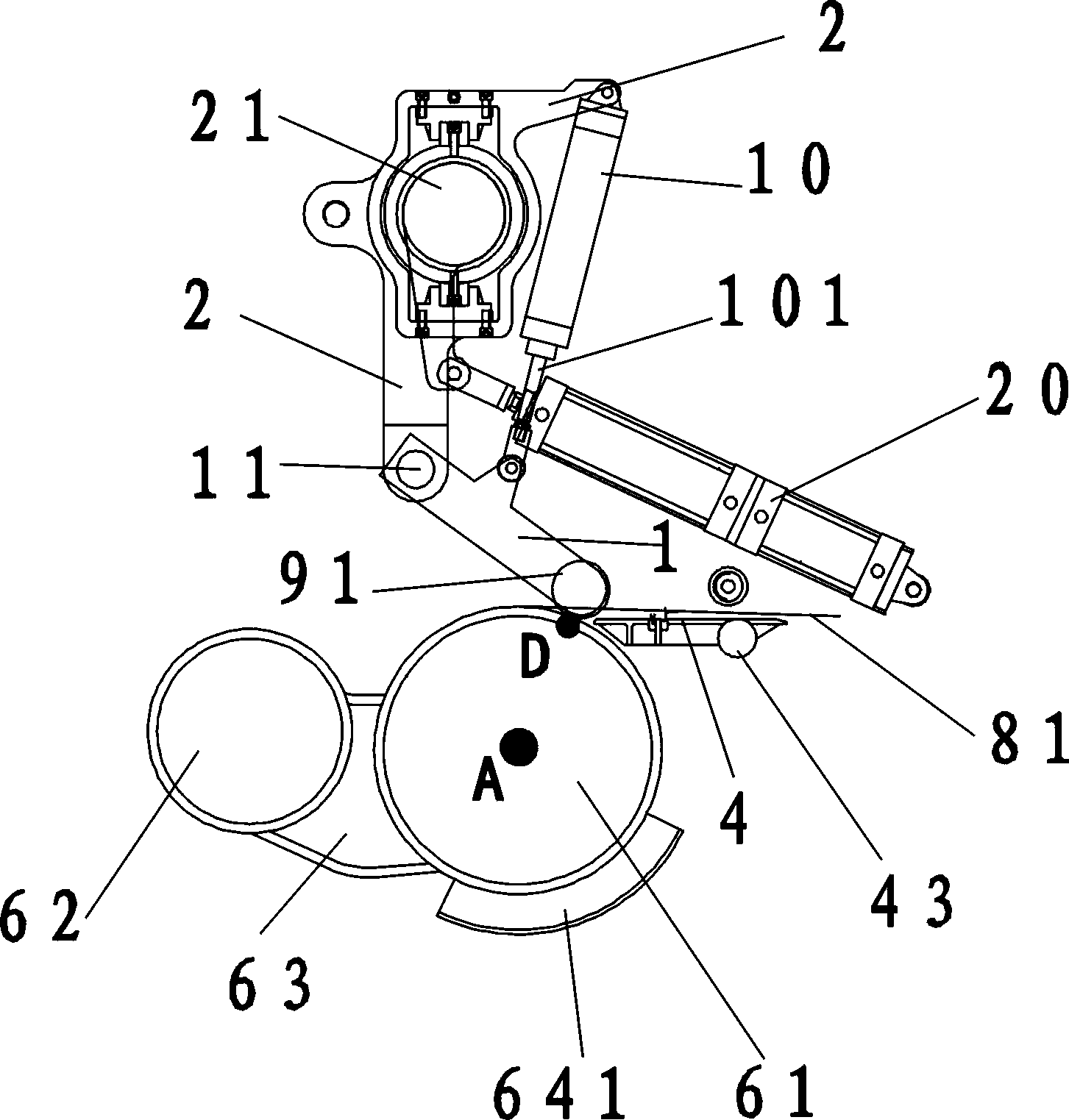

[0046] figure 2 , image 3 , Figure 4 , Figure 5 As shown, the rewinding and changing device of the wide-width film includes a frame on which a core chamber 9 for storing paper core tubes, a cutter 5 for transversely cutting the film, and a cutter 5 for driving the cutter to move laterally are installed on the frame. The cutter driving mechanism 51; the lower end of the storage core chamber 9 is provided with an opening 92, and the opening width of the storage core chamber can accommodate a standard paper core tube 91 to pass through; two small swing arms 1 are also provided to drive the left and right two small swing arms. A small cylinder with a swinging arm. The small cylinder includes a cylinder barrel 10 and a piston rod 101. The piston rod 101 of the small cylinder is connected to the small swing arm 1. The swing ends of the two small swing arms are respectively equipped with chucks that can hold the paper core. 3. There is also a chuck axial drive mechanism 31 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com