Variable polarity arc welding power supply and control method thereof

An arc welding power supply and polarity-changing technology, which is applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problem of unstable welding arc, variable polarity positive and negative half-waves are not easy to control in consistency, and does not consider the direction of the electrode to the mother. The discharge capacity of the material is different, so as to achieve the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0022] [Hardware structure]

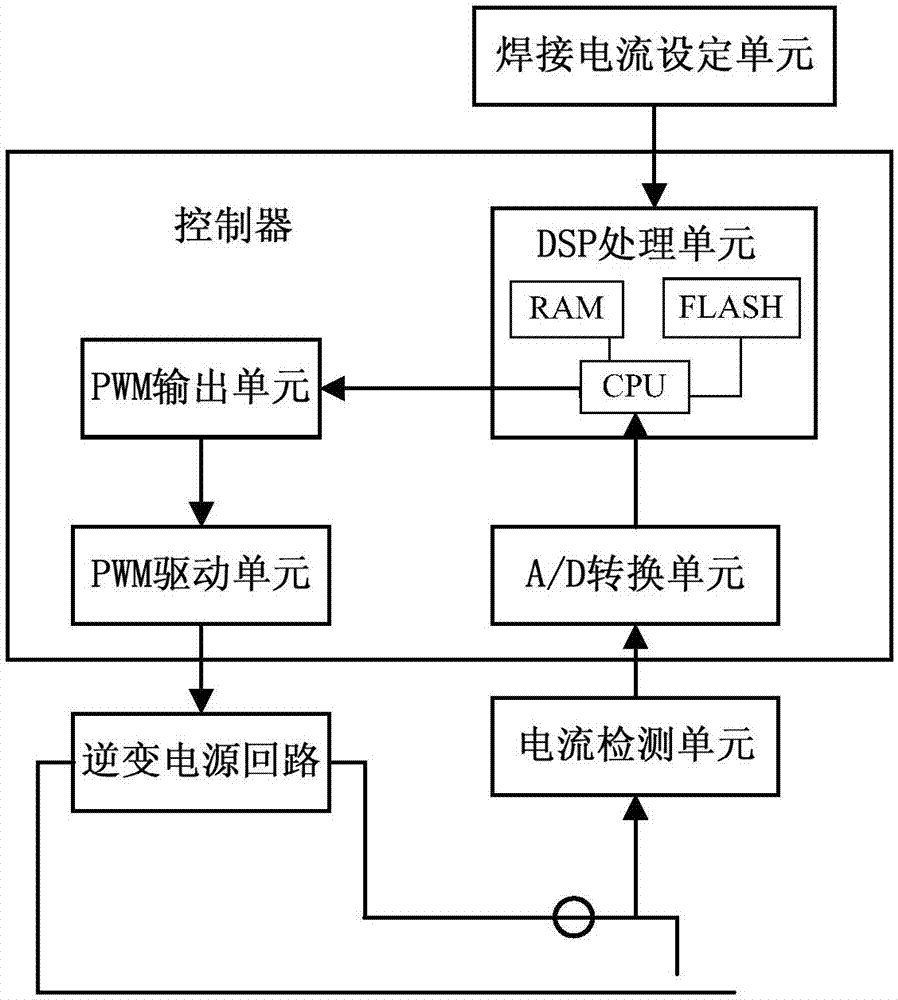

[0023] Refer below figure 1 The hardware structure of the polarity-changing arc welding control device according to the first embodiment of the present invention will be described.

[0024] The polarity-changing arc welding power source shown in this embodiment is a TIG welding power source.

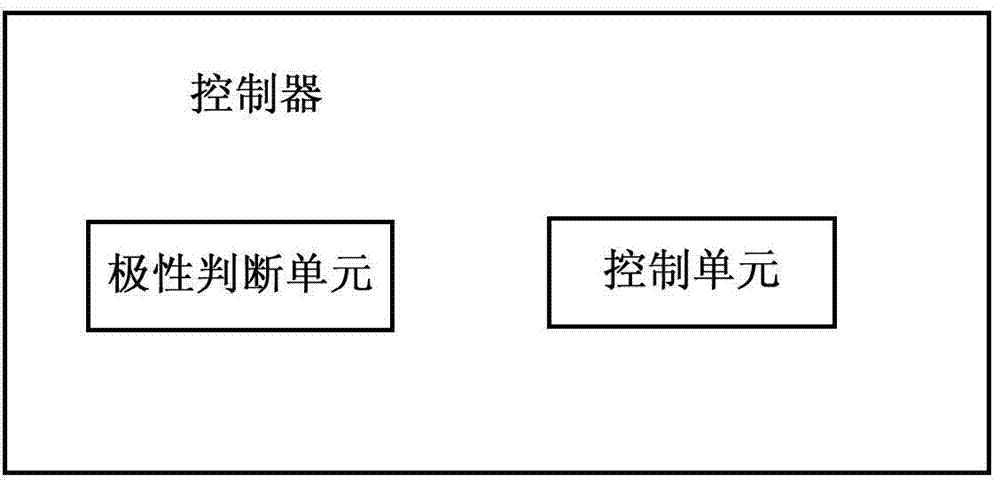

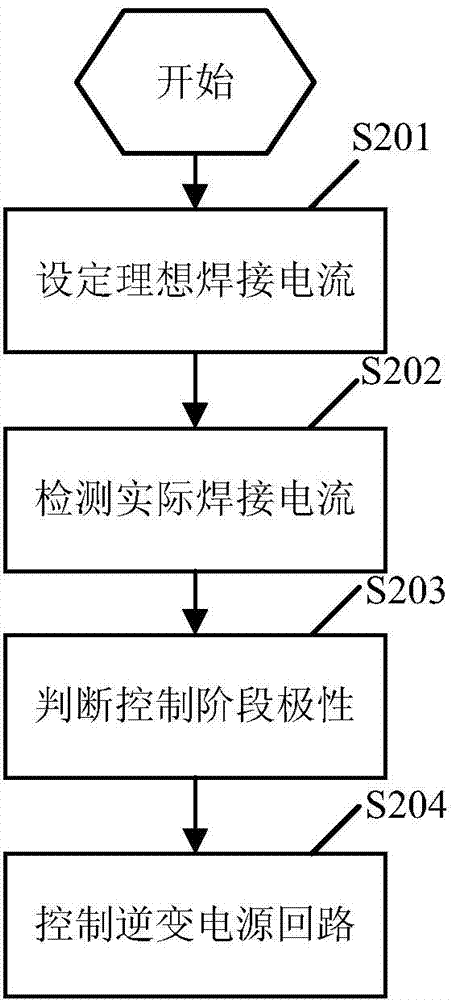

[0025] Such as figure 1 As shown, the variable polarity arc welding power source of the present invention includes: a welding current setting unit, a current detection unit, a controller and an inverter power circuit. The welding current setting unit, the current detecting unit and the inverter power circuit are respectively electrically connected to the controller. The welding current setting unit is used to set an ideal welding current. The current detection unit is used to detect the welding current, which can adopt a current transformer. The inverter power circuit is used to output welding current. The controller is used to control the inverter pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com